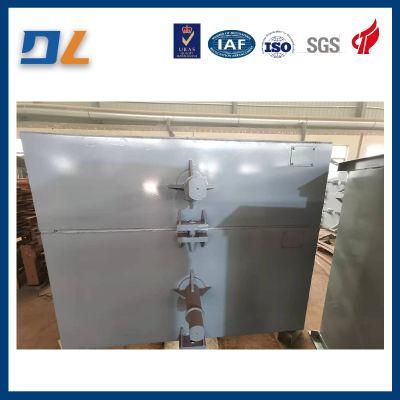

Custom Lost Mold Vacuum Negative Pressure Sand Box

Qingdao Ding Li Machinery Co., Ltd.- After-sales Service:After-Sales Service

- Warranty:One Year Warranty,

- Control Type:PLC

- Customized:Customized

- Condition:New

- Automatic Grade:Automatic

Base Info

- Model NO.:XSM-00

- Certification:CE, RoHS, GS, ISO9001

- Type:Sand Casting

- Transport Package:Custom

- Trademark:DL

- Origin:Qingdao, China

- HS Code:8474802000

- Production Capacity:800

Description

Basic Info.

Model NO. XSM-00 Certification CE, RoHS, GS, ISO9001 Type Sand Casting Transport Package Custom Trademark DL Origin Qingdao, China HS Code 8474802000 Production Capacity 800Product Description

Qingdao Dingli machinery Co., Ltd. is located in the beautiful seaside - Qingdao Pingdu, the company set scientific research, manufacturing, installation and commissioning, after-sales service in one. Mainly produces resin sand production line, clay sand production line, coated sand production line equipment, all kinds of sand processing single equipment. The company has advanced casting machinery manufacturing and development technology, the production of products can fully meet the international and domestic market demand. The company has excellent design and development team, skilled construction team, domestic leading casting equipment design concept, perfect after-sales service system, willing to cooperate with the majority of casting enterprises, create a better tomorrow.In line with the "down-to-earth, integrity-based, pay attention to service, continuous innovation" business philosophy, through continuous efforts. With our own efforts and focus on the development of a series of perfect processing equipment, to meet the different needs of the majority of users.

Lost mode casting (EPC) is a kind of new technology of near zero margin and precise molding. It has no mold taking, no parting surface and no sand core, so the casting has no flanges, burrs and drawing inclination, and reduces the dimensional error caused by core combination. The surface roughness of casting can reach Ra3.2 to 12.5μm. The casting dimension accuracy can reach CT7 to 9; Machining allowance of up to 1.5 to 2mm can significantly reduce machining costs and reduce machining time by 40% to 50% compared to traditional sand casting methods.

Lost mode casting (EPC) is a kind of new technology of near zero margin and precise molding. It has no mold taking, no parting surface and no sand core, so the casting has no flanges, burrs and drawing inclination, and reduces the dimensional error caused by core combination. The surface roughness of casting can reach Ra3.2 to 12.5μm. The casting dimension accuracy can reach CT7 to 9; Machining allowance of up to 1.5 to 2mm can significantly reduce machining costs and reduce machining time by 40% to 50% compared to traditional sand casting methods.Flexible design

It provides sufficient freedom for casting structure design. Highly complex castings can be produced by combination of foam moulds.

There is no sand core in traditional casting

Therefore, there will be no uneven wall thickness of the casting due to the inaccurate size of the sand core or the inaccurate position of the lower core in the traditional sand casting.

Cleaner production

There is no chemical binder in the molding sand, the foam plastic is harmless to the environment at low temperature, and the recovery rate of used sand is above 95%.

Reduce investment and production costs

Reduce the weight of casting blank, small machining allowance.

Disadvantages and Limitations

The lost mode casting process, like other casting processes, has its shortcomings and limitations. Not all castings are suitable for production by lost mode casting process. The adoption of this process is mainly based on the following factors. 1. The larger the batch of castings, the more considerable the economic benefit. 2. The order of good and bad applicability of casting material is roughly: gray cast iron -- non-ferroalloy -- ordinary carbon steel -- nodular cast iron -- low carbon steel and alloy steel; Make necessary preparations so as not to prolong the process test and commissioning cycle. 3. The casting size mainly considers the use range of the corresponding equipment (such as vibrating table, sand box). 4. Casting structure The more complex the casting structure, the more the advantages and economic benefits of lost mode casting process can be reflected. For the case of narrow inner cavity passage and interlayer in the structure, the lost mode process needs to be tested in advance before it can be put into production.

folding

Note: the size of the sand box below is for reference only, the specific size is the standard provided by the buyer

| The name of the | Lost mold sand box | Lost mold sand box | Lost mold sand box | Lost mold sand box | Lost mold sand box | Lost mold sand box | Lost mold sand box |

| (XX) | 2000X1000X900 | 2200X1200X1000 | 2500X1500X1200 | 2800X1600X1200 | 3000X1800X1500 | 3300X2000X1700 | 3500X2200X2000 |