High Productivity Stainless Steel Circular Gear Saw Blade

Nanjing Shanduan Cnc Machine Tool Co., Ltd.- Condition:New

- Certification:CE

- Standard:GB

- Customized:Customized

- Material:Packing

- Application:Metal Cutting Machine

Base Info

- Transport Package:Standrad

- Trademark:YSDCNC

- Origin:Nanjing

- HS Code:8208900000

Description

Basic Info.

Transport Package Standrad Trademark YSDCNC Origin Nanjing HS Code 8208900000Product Description

High productivity stainless steel circular Gear saw blade

machine cutting blade

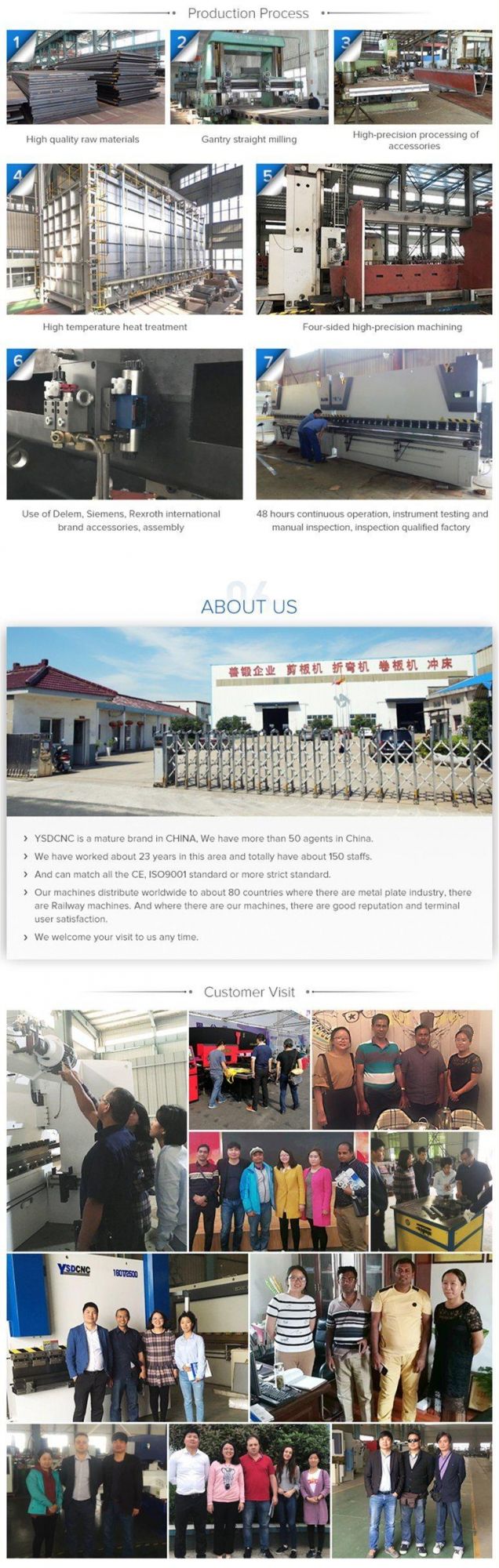

Nanjing Shanduan CNC Machine Tool Co., Ltd is one of the Top 3 press brake and shearing machine in China, which specializing in manufacturing and marketing of press brake,shearing machine,press machine, square duct production line LINE5,4,3,2,1;spiral duct machine, locking forming machine;folding machine,plasma cutting machine, power press,ironworker,hydraulic notching machine, beading machine,flange forming machine,shearing machine & press brake,Blade/Mold, etc.

| Company Name (manufacturer): Nanjing Shanduan CNC Machine Tool Co., Ltd. |

| Brand: YSDCNC |

| Address: MINGJUR INDUSTRIAL CONCENTRATION DISTRICT,SHIQIU TOWN,LISHUI AREA,NANJING,JIANGSU |

| Tel:+86 025-57262305 Phone:+86 18851629789 |

| Website: www.ysdcnc.com |

Gear saw blade:

The different kinds of tooth forms are used according to different requirements of cutting.

How to choose the right tooth form?

1.Tooth form "A" and "AW"

For thin Metal Slitting carbide gear milling cutters with a tooth pitch up to approx. 3.0mm Advisable for brass, tooth form "A" is

suitable for slotting materials. All teeth of tooth form "AW" are bevelled alternatively.

2.Tooth form "B" and "BW"

Suitable for cutting tubes and profiles made of steel or non-ferrous metals. Tooth form "B" is specialized for cutting very thin walled popes and profiles. All teeth of tooth form "BW" are bevelled alternatively.

3.Tooth form HZ

This tooth is also known as form "HZ". Teeth are ground according to the roughing and finishing tooth system. A tooth pair is consisting of one roughing tooth(1/3 cutting width) and one finishing tooth(2x1/3 cutting width). According to the triple chip geometry the roughing tooth is approx.0.2-0.3mm higher compared with the finishing tooth. Tooth form "HZ" is suitable for cutting solid materials.

4.Tooth Form BR

Tooth form BR is a parrot tooth with chip breaker.This tooth form is sutiable for cutting pipes under high performance conditions because the teeth are side cutting.

machine cutting blade