Fine Quality Mill Mandrel for Producing Seamless Steel Tubes

Yantai Fangle Metallurgy Group Co., Ltd.- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

- Application Range:Fine Quality Mill

Base Info

- Model NO.:as the drawing

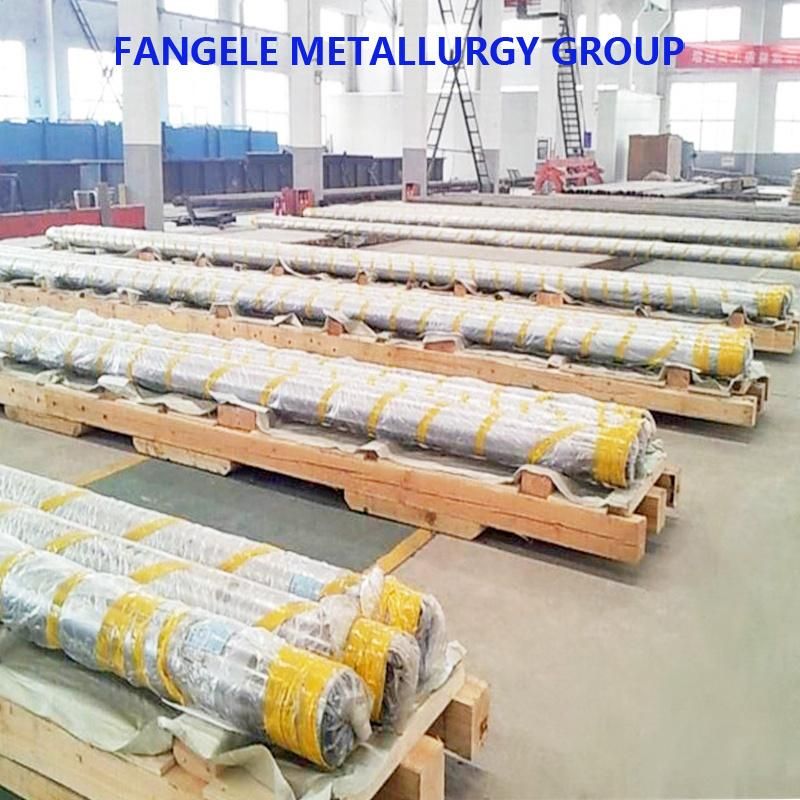

- Transport Package:Woodern Case

- Specification:length max 20m

- Trademark:FANGLE

- Origin:China

- Production Capacity:50000tons,Year

Description

Basic Info.

Model NO. as the drawing Transport Package Woodern Case Specification length max 20m Trademark FANGLE Origin China Production Capacity 50000tons/YearProduct Description

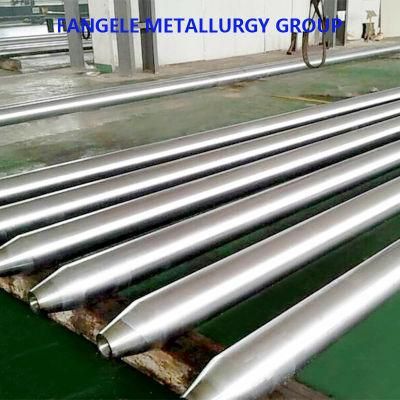

MPM & PQF mandrel bars are also named retained mandrels.Mandrel bars are the key parts during the production of Seamless Tubes and Pipes. Once the billet has been pierced, the Mandrel Bar supports the tube internally during elongation and wall thickness reduction.Mainly technical parameters are below:

(1)Diameter : up to 500mm;

(2)Length: max to 20,000mm;

A variety of seamless tube mill types including;

MPM, PQF and FQM mills;

Assel Mills - both floating and retained;

Material specification as required, including AISI H13, X35CrMo V51 and 4CrMoSi V1;

Threading available ;

Chrome plating;

Both solid and hollow bars.

Detail specification:

Material: H13, 4Cr5MoSiV1;

Range of dimensions: 80-600mm

Length: 8000-18000mm

Dimension tolerance:+0, -0.2mm

Roughness:Ra 0.4μm

Chromic Plating thickness:0.045-0.065mm

Straightness tolerance per meter:≤1mm

Length tolerance:±2mm

Workpiece rotate speed:80rpm

Process route: EAF+VD+LF+ESR;

Application:Mandrel Bars for seamless tube production like PQF/MPM/FQM Rolling Mill, Assel Mill, Accu-roll mill, Push Bench, Pilger mill etc

Manufacturing process:

Steel making (EBT + LF (VD) + ESR);

Forged using both hydraulic press and rotary forging;

Annealing;

Rough machining;

Magnetic testing;

Heat treatment - either vertical or horizontal;

Ultrasonic testing;

Finish machining including threading if required;

Chrome plating; and

Thread phosphating.

Chemistry(%)

Chemical Components of H13(4Cr5MoSiV1)

| C | Si | Mn | S | P | Cr | Mo | Ni | V | H | O |

| 0.32~0.45 | 0.80~1.20 | 0.20~0.50 | ≤0.008 | ≤0.012 | 4.75~5.50 | 1.10~1.75 | ≤0.25 | 0.80~1.20 | ≤2PPm | ≤2PPm |