PLC Control Induction Scanning Tools for Metal Quenching

Dongguan Guangyuan Inverter Electronic Equipment Factory- Warranty:12 Months

- Feature:High Efficiency

- Customized:Customized

- Duty Cycle:100%

- Cooling:Water

- System Control:IGBT

Base Info

- Model NO.:GY-PLC1000

- Work Condition:Continuously for 24hours

- Work Principle:Electromagnetic Induction Heating

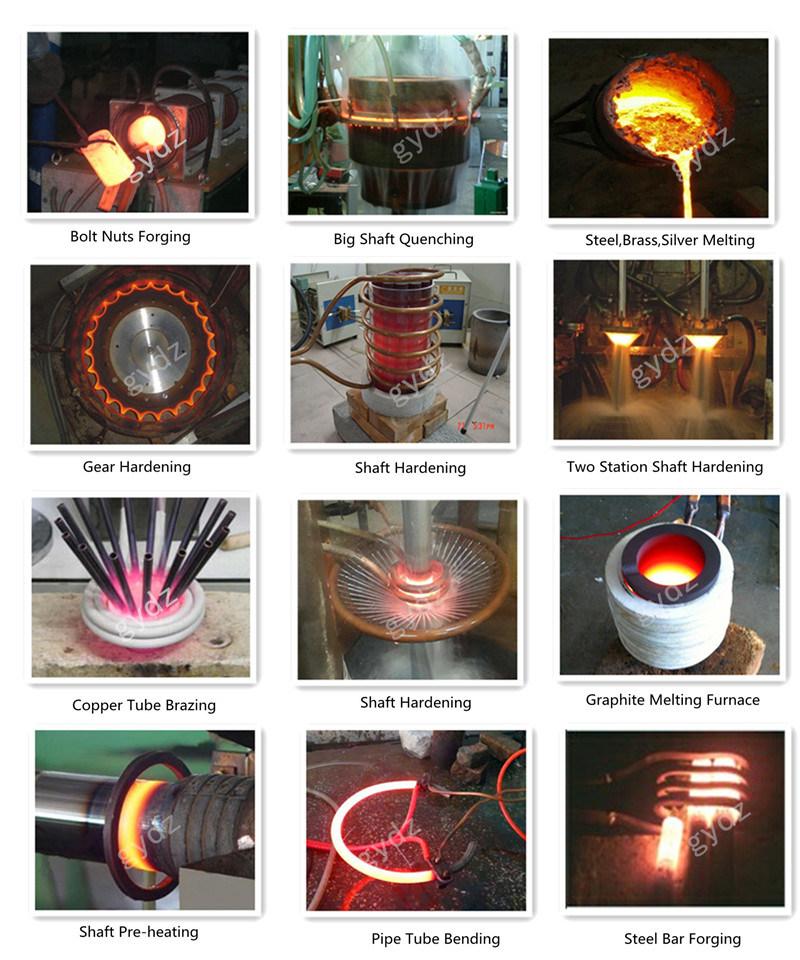

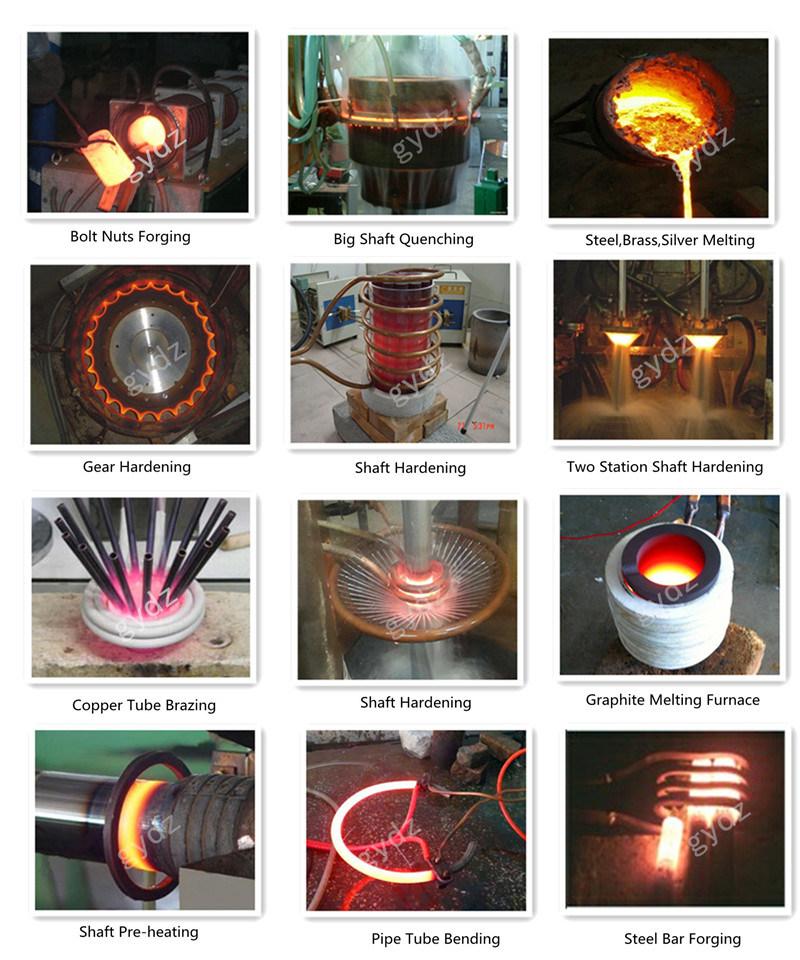

- Application:Heating, Forging, Melting, Hardening and etc

- Heat Transfer Surface:Tubular Heat Exchanger

- Transport Package:Wooden Boxes

- Trademark:GY

- Origin:Dongguan, China

- HS Code:85144000

- Production Capacity:300sets Per Month

Description

net weightmain : 150gks transformer : 120kgs

Delivery Time: within 7 workdays.

Shipping Term:By sea,By air,by express.

Extra accessories accept choose,

1>Chiller

2>Customer design Coil

3>Infrared Thermometer

4>Back-up Electronic Boards

5>Forging Furnace,Melting Furnace,Hardening Fixture

Induction hardening is a process used for the surface hardening of steel and other alloy components. The parts to be heat treated are placed inside a water cooled copper coil and then heated above their transformation temperature by applying an alternating current to the coil. The alternating current in the coil induces an alternating magnetic field within the work piece, which if made from steel, caused the outer surface of the part to heat to a temperature above the transformation range. Parts are held at that temperature until the appropriate depth of hardening has been achieved, and then quenched in oil, or another media, depending upon the steel type and hardness desired. The core of the component remains unaffected by the treatment and its physical properties are those of the bar from which it was machined or preheat treated. The hardness of the case can be HRC 37 - 58. Carbon and alloy steels with a carbon content in the range 0.40 - 0.45% are most suitable for this process. In some cases, parts made from alloy steels such as 4320, 8620 or 9310, like steel and paper mill rolls, are first carburized to a required case depth and slow cooled, and then induction hardened. This is to realize the benefit of relatively high core mechanical properties, and surface hardness greater than HRC 60, which provides excellent protection.

While induction hardening is most commonly used for steel parts, other alloys such as copper alloys, which are solution treated and tempered, may be induction hardened as well. Applications include hardening bearing races, gears, pinion shafts, crane (and other) wheels and treads, and threaded pipe used for oil patch drilling.

About service question

Q: Why choose GuangYuan Company?

A: We are manufacture which had in this filed for nearly 20 years.No matter quality,price,service,delivery time,we all have large advantage.

Q:How to choose suitable machine?

A:You can tell us your application,need forging,hardening,welding,melting or other,pass me workpiece material & size,Temperature requirement and heating time requirement.Then we will recommend fit machine for you reference.

Q:How about the machine payment term&delivery time&Shipping term?

A: Our company payment term accept T/T,Western Union,L/C and so on.Small machine delivery time is 3~7 workdays.Big machine delivery time 15~25 workdays.Shipping term accept EXW,FOB,CIF and so on.

Q:How about the machine warranty?

A:Our goods support one year warranty not by personal purpose,support technical service all life.

During the warranty,if machine have problem need change spare parts,we can replace for you charge free

| Model | GY-PLC1000 |

| Maximum clamping parts length | 1000mm |

| Maximum quenching diamention | 100mm |

| Maximum workpiece weight | 200kg |

| Workpiece travel speed | 1-30mm/s |

| Workpiece updown speed | 120mm/s |

| Rotating speed | 1-200r/min |

| Cooling way | immersion ,spray, |

| Machine size after packing | 2440*1320*900MM |

| Operation | automatically or manually |

Delivery Time: within 7 workdays.

Shipping Term:By sea,By air,by express.

Extra accessories accept choose,

1>Chiller

2>Customer design Coil

3>Infrared Thermometer

4>Back-up Electronic Boards

5>Forging Furnace,Melting Furnace,Hardening Fixture

Induction hardening is a process used for the surface hardening of steel and other alloy components. The parts to be heat treated are placed inside a water cooled copper coil and then heated above their transformation temperature by applying an alternating current to the coil. The alternating current in the coil induces an alternating magnetic field within the work piece, which if made from steel, caused the outer surface of the part to heat to a temperature above the transformation range. Parts are held at that temperature until the appropriate depth of hardening has been achieved, and then quenched in oil, or another media, depending upon the steel type and hardness desired. The core of the component remains unaffected by the treatment and its physical properties are those of the bar from which it was machined or preheat treated. The hardness of the case can be HRC 37 - 58. Carbon and alloy steels with a carbon content in the range 0.40 - 0.45% are most suitable for this process. In some cases, parts made from alloy steels such as 4320, 8620 or 9310, like steel and paper mill rolls, are first carburized to a required case depth and slow cooled, and then induction hardened. This is to realize the benefit of relatively high core mechanical properties, and surface hardness greater than HRC 60, which provides excellent protection.

While induction hardening is most commonly used for steel parts, other alloys such as copper alloys, which are solution treated and tempered, may be induction hardened as well. Applications include hardening bearing races, gears, pinion shafts, crane (and other) wheels and treads, and threaded pipe used for oil patch drilling.

About service question

Q: Why choose GuangYuan Company?

A: We are manufacture which had in this filed for nearly 20 years.No matter quality,price,service,delivery time,we all have large advantage.

Q:How to choose suitable machine?

A:You can tell us your application,need forging,hardening,welding,melting or other,pass me workpiece material & size,Temperature requirement and heating time requirement.Then we will recommend fit machine for you reference.

Q:How about the machine payment term&delivery time&Shipping term?

A: Our company payment term accept T/T,Western Union,L/C and so on.Small machine delivery time is 3~7 workdays.Big machine delivery time 15~25 workdays.Shipping term accept EXW,FOB,CIF and so on.

Q:How about the machine warranty?

A:Our goods support one year warranty not by personal purpose,support technical service all life.

During the warranty,if machine have problem need change spare parts,we can replace for you charge free