PVD Vacuum Coating Machine/Painting Line UV Line for Auto Parts

Ningbo Danko Vacuum Technology Co., Ltd.- Type:Coating Production Line

- Coating:Vacuum Coating

- Substrate:Plastic Automotive Parts

- Certification:CE, ISO, TUV

- Condition:New

- Machine:PVD Vacuum Coating Machine for Metallizing Plastic

Base Info

- Model NO.:DK

- Weight:1.5t

- Business Type:Manufacturer

- Coating Filml:Decorative Film

- After Sales Service:Engineer Available to Service on Site

- Other Service:24h, Remote Guidance

- Application:Plasatic Metallizing

- Film Color:Golden Color

- Structure Type:Vertical or Horizantal Type

- Controlling System:PLC Touching Screen

- Transport Package:Wood Case, Container

- Specification:1600*1800

- Trademark:DANKO

- Origin:Ningbo, China

- HS Code:8479899990

- Production Capacity:1000sets , Year

Description

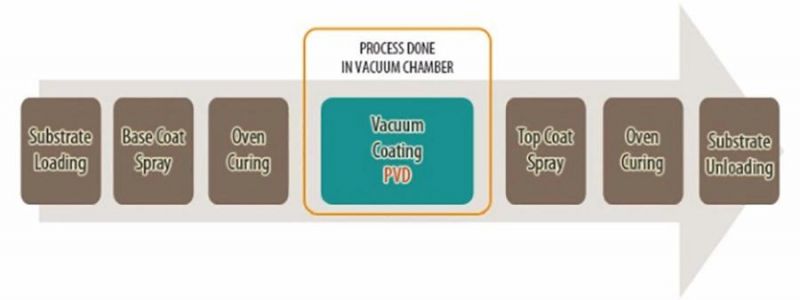

Process

Application

A. Car light reflective film

B. Automotive head lamp, rear lamp, turn light

C. Car logo

D. Car wheel

Advantages

A. Fast to film forming, with high deposition speed;

B. It can make auto-lamp get the metal effects, nice appearance and reflection effect.

C. Complete evaporation coating aluminum and plating protective film process steps by one time inside chamber room

D. By using nanotechnology.

E. High pumping speed can complete a round of plating in about 7 or 8 minutes

F. Without any gas or liquid wasted

G. Working stably with good vacuum performance

H. Customized processing services

I. High Standards to control quality

Configurations

A. Pumps:

Mechanical pump + roots pump + diffusion pump + holding pump (or optional: cryogenic pump, cryogenic pump system)

B. Limited Vacuum: 8*10-4 pa (cleanroom, no-loading)

C. Shaft: 6 / 8 /9 shafts

D. Power Sources: Resistance heating tungsten wire evaporator power supply, high voltage ion bombardment power supply, thyristor power supply

E. Controlled by Manual, Semi-automatic, Full automatic, PLC

Customer visit

Shipment

Workshop

For more details on configurations quotations, please contact us.

Ningbo Danko Vacuum Technology Co.,Ltd

https://dankovac.en.made-in-china.com

Sara