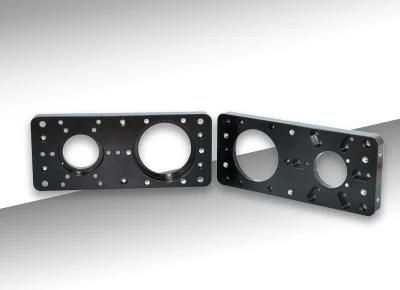

Customized High Precision CNC Machining Aluminum Alloy Profile Parts

Ningbo Hento Metal Products Co., Ltd.- After-sales Service:Maintenance

- Warranty:1 Year

- Condition:New

- Certification:CE, RoHS, GS, ISO9001

- Standard:DIN, ASTM, GOST, GB, JIS, ANSI, BS

- Customized:Customized

Base Info

- Material:Aluminum

- Application:Metal Cutting Machine, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

- Transport Package:Carton

- Specification:precision customized

- Trademark:Hento

- Origin:China

- HS Code:84779000

- Production Capacity:10000PCS ,Month

Description

Our AdvantagesReliable Quality Competitive Price High precision, high quality, tight tolerance On-Time Delivery Continuous Improvement Defect-Free Products Customer Satisfaction Excellent After-Sales Service No. Name Model Q'TY Equipment Manufacturer Size Spec./ Range of Work Machine Accuracy 1 CNC machining center 850(950*520) 10 HANVOS ¢500*800(D*L) 0.002 2 CNC machining center V52(750*420) 2 HANVOS ¢400*600(D*L) 0.002 3 CNC machining center V64(1300*600) 1 HANVOS ¢600*1000(D*L) 0.002 4 CNC lathe SX-6136P/450 9 ShengXiang ¢150*400(D*L) 0.005 5 CNC lathe SX-6150/450 2 ShengXiang ¢150*400(D*L) 0.01 6 CNC lathe CJK0640B 2 YaoFa 200*500(D*L) 0.01 7 CNC lathe D370 1 David Beijing 300*700(D*L) 0.005 8 Benchtop tapping machine SWJ-6 3 West Lake ¢1-¢25 9 Bench boring machine Z512-2 2 West Lake ¢1-¢20 10 Laser marking machine JG300/200 1 HongGuang 300*200(L*L)

About Hento

Ningbo Hento Metal Products Co., LTD, located in Ningbo City, Zhejiang Province, China, is a professional manufacturer integrated with production and research & development.

Products are widely used in industries such as petroleum, electric power, automobile, food, chemical engineering, railway, mining, steel, shipbuilding and machinery etc.;

Our main products are silica sol precision casting, forging and precision machining of stainless steel 304, 304 L, 304, 316 L and A182 - F316L; other related materials: zinc alloy, alloy steel, brass, lead-free copper, ductile iron, grey iron, etc.; related technology: precision casting, forging, zinc-aluminum die-casting, punching press, welding, structural section and bar processing etc.

The tolerance of finished products can be controlled within 0.01 mm (0.0004 in); and the roughness can be controlled at Ra0.4

90% of Products are exported to countries and regions such as the United States and the European Union

Manufacturing equipment: 4-axis CNC machining center; CNC lathe; and related auxiliary equipment;

Test equipment: advanced testing methods and equipment such as tensile strength tester, hardness tester, projector and CMM are adopted to ensure production process

Surface treatment: powder spraying, painting, electroplating, electrophoresis and polishing, etc.

Working Time

Part of our Test Equipment

Part of our Test Equipment

About Hento

Ningbo Hento Metal Products Co., LTD, located in Ningbo City, Zhejiang Province, China, is a professional manufacturer integrated with production and research & development.

Products are widely used in industries such as petroleum, electric power, automobile, food, chemical engineering, railway, mining, steel, shipbuilding and machinery etc.;

Our main products are silica sol precision casting, forging and precision machining of stainless steel 304, 304 L, 304, 316 L and A182 - F316L; other related materials: zinc alloy, alloy steel, brass, lead-free copper, ductile iron, grey iron, etc.; related technology: precision casting, forging, zinc-aluminum die-casting, punching press, welding, structural section and bar processing etc.

The tolerance of finished products can be controlled within 0.01 mm (0.0004 in); and the roughness can be controlled at Ra0.4

90% of Products are exported to countries and regions such as the United States and the European Union

Manufacturing equipment: 4-axis CNC machining center; CNC lathe; and related auxiliary equipment;

Test equipment: advanced testing methods and equipment such as tensile strength tester, hardness tester, projector and CMM are adopted to ensure production process

Surface treatment: powder spraying, painting, electroplating, electrophoresis and polishing, etc.

Working Time

Part of our Test Equipment

Part of our Test Equipment