Sink Roll, One of The Very Important Spare Parts of Hot DIP Galvanizing Unit

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Stainless Steel

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Transport Package:Woodern Case

- Specification:Export package

- Trademark:FANGLE

- Origin:China

- Production Capacity:20000tons,Year

Description

Basic Info.

Model NO. as the drawing Transport Package Woodern Case Specification Export package Trademark FANGLE Origin China Production Capacity 20000tons/YearProduct Description

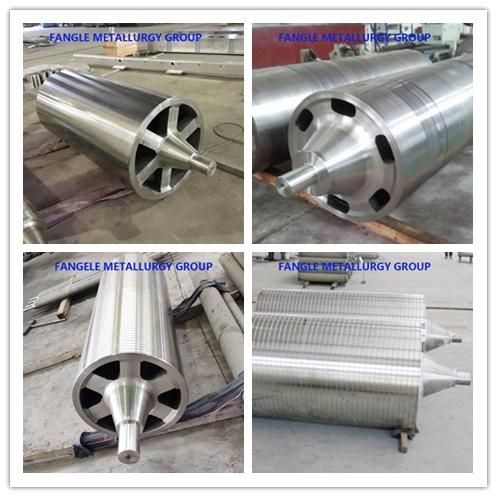

sink roll, one of the very important spare parts of hot dip galvanizing unitDescription

Sink roll is in continuous hot galvanizing production line work in molten zinc base alloy slot roller, is an important part of a hot dip galvanizing unit, out of the annealing furnace of strip hot galvanizing technology through sink roll, the quality of the sink roll and running state directly affects the quality of the surface of galvanized steel, its service life determines the production efficiency and running cost of the unit.

In the metallurgy industry, in order to get high qualified galvanized products, sink rolls play very important role in the continuous hot dip galvanizing line. Sink roll is one of the three rolls in CGL (continuous galvanizing line); Along with other two rolls, stabilizer roller and back-up roller, they are the main composition of continuous galvanizing line.

Material : Sink roll is used in zinc pot,usually produced with 316L or 317L.

Working condition : Working temperature is 500ºC-700ºC. It plays a turning role the whole sink roll assembly. In the process of production, the whole sink roll is immersed into molten zinc liquid. Cooperated with stabilizer roll, agitating molten zinc liquid to the surface of plate. The surface structure and quality of the sinking roller will directly affect the galvanizing quality of the sheet and affect its service life. Therefore, the sinking roller is one of the key factors determining the production quality and production efficiency of the galvanizing line.

Products Parameters

| Materials | 316L,317L,316,HK,HT,HU,HP,HH,22H,HF,Super 22H etc. |

| Diameter | Mainly100-1600mm, or as requirements |

| Process | Centrifugal casting Sink roll body, static casting Cone |

| Hardness | Meet the customers' requirements |

| Surface Processing | Thermal Spraying: cermet; Prax air coating LCO-56/LC1C |

| Quality tests | composition by spectrometer, size test, mechanical test, NDT/UT/RT/PT/MT/ET |

| Lead time | about 45 days |

| Delivery condition | Finished machining |

| Application | CGL (Continuous hot dip galvanizing line),Plating aluminizing line, Plating silicon line |

| Market | India,Saudi Arab,Russia,Slovenia,Thailand,Vietnam etc. |

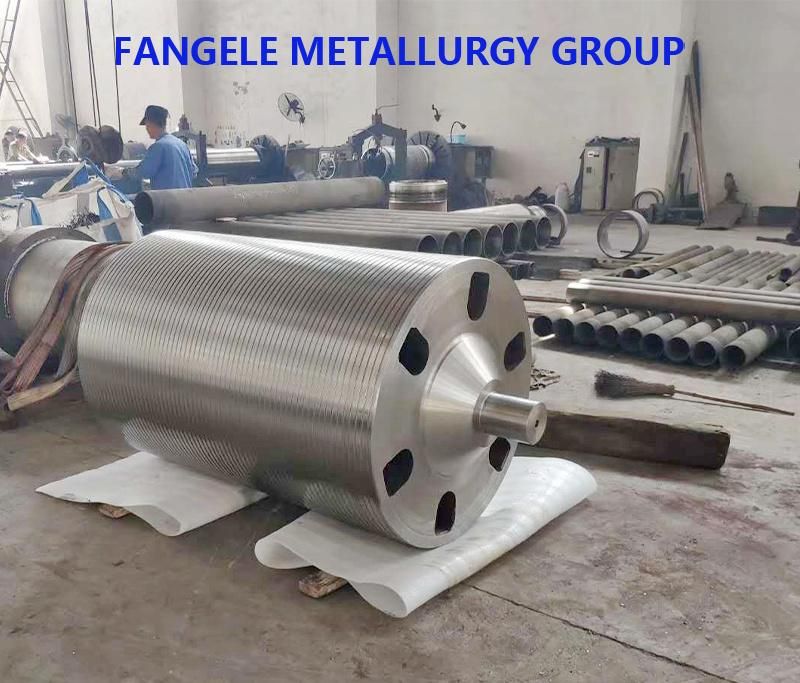

Products show

Workshop show

Customer Visit