Piercer Plug Used for Piercing Mill Process

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Cast Steel

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Application Range:Piercer Mill,Plug Bar Assembly

- Transport Package:Woodern Case

- Specification:Cast steel, 35CrMo, H13, 20CrNi4 etc.

- Trademark:FANGLE

- Origin:China

- Production Capacity:30000tons,Year

Description

Basic Info.

Model NO. as the drawing Application Range Piercer Mill,Plug Bar Assembly Transport Package Woodern Case Specification Cast steel, 35CrMo, H13, 20CrNi4 etc. Trademark FANGLE Origin China Production Capacity 30000tons/YearProduct Description

Piercer plug used for piercing mill process

Brief introduction

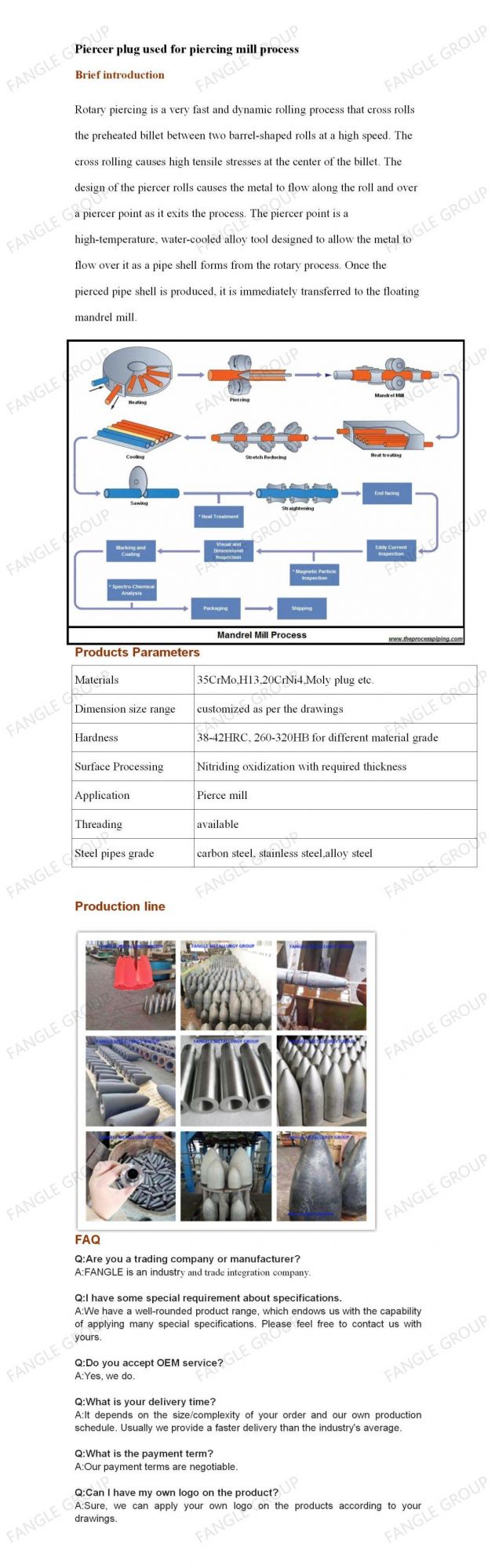

Rotary piercing is a very fast and dynamic rolling process that cross rolls the preheated billet between two barrel-shaped rolls at a high speed. The cross rolling causes high tensile stresses at the center of the billet. The design of the piercer rolls causes the metal to flow along the roll and over a piercer point as it exits the process. The piercer point is a high-temperature, water-cooled alloy tool designed to allow the metal to flow over it as a pipe shell forms from the rotary process. Once the pierced pipe shell is produced, it is immediately transferred to the floating mandrel mill.