Steel Parts Aluminum Parts Fabrication CNC Machining Factory Supplying

Luckym Technology (HK) LIMITED- After-sales Service:After Sales Services

- Warranty:After Sales Services

- Condition:New

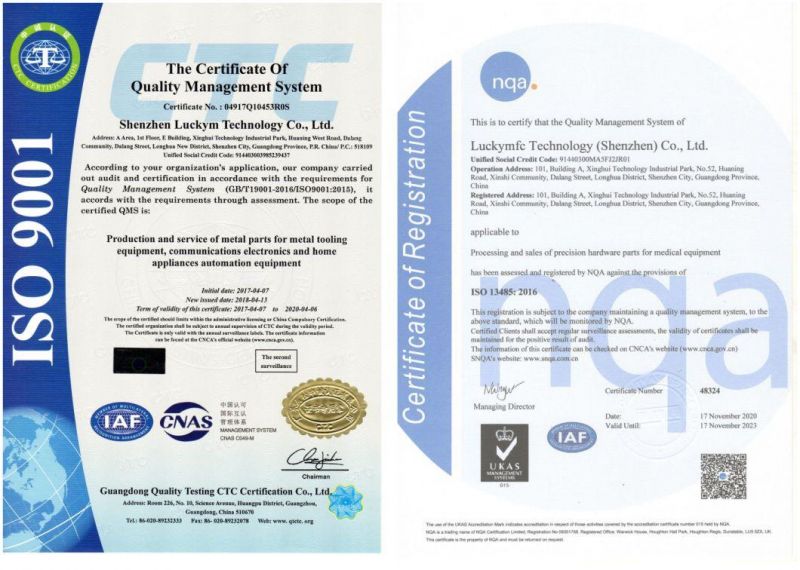

- Certification:RoHS, ISO9001

- Standard:DIN, ASTM, GB, JIS, ANSI, BS

- Customized:Customized

Base Info

- Model NO.:custom-made

- Material:Stainless Steel

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

- Materials:Stainless Steel

- Fitting:Fitting Parts Copmonents

- Type:Insert Parts Components

- Processing:CNC Machining

- Precision:High Precision

- Transport Package:Standard Export Carton or Customized

- Specification:Customized

- Trademark:N,A

- Origin:China

- Production Capacity:50000

Description

Basic Info.

Model NO. custom-made Material Stainless Steel Application Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery Materials Stainless Steel Fitting Fitting Parts Copmonents Type Insert Parts Components Processing CNC Machining Precision High Precision Transport Package Standard Export Carton or Customized Specification Customized Trademark N/A Origin China Production Capacity 50000Product Description

OEM&ODM ( Single piece customization)

CNC Machining parts ,CNC milling parts, CNC turning parts,Grinding parts,Wire cutting parts,Assembly parts,tooling fixtures, special kinds of automated device etc.

Stainless steel component Milling parts with metal brass copper insert part for heavy equipment

Custom-made stainless steel Parts for Valve and Pump System, Medical Equipment,Optical Instrument, Electronic Machine, Automatic Robotic system, Laser machinery

Brief introduction of Luckym :

| Our Product Application Spectrum: | |

| Application 1 | Automation systems, Test systems. |

| Application 2 | 3C (Computer,Communication,ConsumerElectronic). |

| Application 3 | Food, Printing,Textile machinery, Optical, Lighting, Security and safety. |

| Application 4 | Home appliance, Pumps, Power and energy, Agriculture. |

| Metal Fabrication Capacity: | |

| Material spectrum | Stainless Steel, Aluminum Alloys,Aluminum, Brass, Bronze, Brass, Carbon steel, Chrome steel, Cold rolled sheet, Bearing steel, Chrome copper, Mold steel, Plastic, Teflo, Fiber glass etc. |

| Machining processing 1 | CNC machining center (For more pictures pls reference the content of "Home Page ") |

| Machining processing 2 | Lathe,Turning,Millling,Grinding. |

| Machining processing 3 | Cutting, Welding ,Stamping, Die casting ,Punching,Aluminum Extrusion. |

| Precision control | 0.005mm for Metal Part / 0.1mm for Plastic Part |

| Value added | Lasering, Engraving,Boring,Broaching,Drilling,Rolling ,Tapping |

| Surface treatment | Anodize, Vacuum plating, Nickel, Chromate ,Zinc, Titanium, Tin Brass, Silver, Gold plating, Paint, Powder coating, Passivation, Electrolytic polishing, Sandblasting, Brushing, Gas nitriding etc. |

| File Formats | PDF ,JPG, , CAD (DXF,DWG) ,Pro/E ,SolidWorks, UG (IGS,STP,X-T) . ( 2D or 3D drawing) |

| Quality System and the Environment: | |

| Management System | ISO9001 , PND Production Management. |

| Available Certificate | RoHS, SGS, Material Cert , Treatment Cert. |

| Accident Prevention | Safty Operation Management. |

| Quality Control | Liability System and Technican self-inspection , Periodical QC on line per hour ,Final inspection 100% from each lot ,standard inspection report |

Certification

Packaging :

(Inner: PE bag/bubble bag or customized. Outer: standard carton or wooden case or customized.)

Logistics :

By international express to global is around 7-10 working days to be reached (DHL/UPS/TNT/EMS/FEDEX etc. as per demand).

For sea shipment to global is around 15-20 working days to be reached.

Customer visiting

Each of our products are manufactured to assure quality ,accuracy and dependability for constant assembly production requirement for clients,clients will benefit a lot from our services either the time or cost.

That's what we valued to our customers , may we know what's your needs ? from below you can send us a message.

Looking Forward to Our Cooperation !