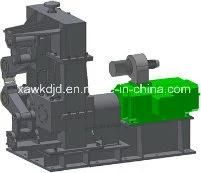

Steel Cutting Equipment

Xi'an Weikeduo Electrical & Mechanical Equipment Co., Ltd.- Structure:Vertical

- Spinning Strength:High Power Spinning

- Pressure Supply Type:Atmospheric Pressure

- Spinning Direction:Reverse

- Metal Material:Steel

- Riveting Principle:Orbital Models (BM Series)

Base Info

- Model NO.:HJ-005

- Spinning Deformation Condition:Hot Spinning

- Spinning Belt Wheel Type:Combined Belt Wheel

- Spinning Wheel Number:Double

- Finished Product:Belt Wheel

- Finished Product Shape:Cylinder Shape

- Steel to Be Processed:Steel to Be Processed

- Material Diameter:Dia12.7_Dia18

- Rolling Speed:7-12m,S

- Cutting Temperature:850°c

- Product Length:150~230mm

- Rotary Sword Diameter:800mm

- Motor Power:112kw

- Motor Speed:255-465r,Min

- Transport Package:Seaworthy Packing

- Specification:ISO9001, SGS, BV

- Trademark:Hangji

- Origin:China

- HS Code:8455213000

- Production Capacity:300sets,Year

Description

Basic Info.

Model NO. HJ-005 Spinning Deformation Condition Hot Spinning Spinning Belt Wheel Type Combined Belt Wheel Spinning Wheel Number Double Finished Product Belt Wheel Finished Product Shape Cylinder Shape Steel to Be Processed Steel to Be Processed Material Diameter Dia12.7_Dia18 Rolling Speed 7-12m/S Cutting Temperature 850°c Product Length 150~230mm Rotary Sword Diameter 800mm Motor Power 112kw Motor Speed 255-465r/Min Transport Package Seaworthy Packing Specification ISO9001, SGS, BV Trademark Hangji Origin China HS Code 8455213000 Production Capacity 300sets/YearProduct Description

1.Equipment composition and structural characteristics.

Flying shear is composed by transmission equipment, cutting support base and upper & lower spindle. Rotary tool rest has installed backsword, two spindles which are parallel with start-stop work system. Tool rest makes one revolution to finish one cutting period. Motor drive the spindle through reduction gears and make the upper, lower spindle rotated through the gear.

The lower spindle is connected with transmission equipments. Motor adapt separately ventilated machine and equipped speed measuring motor to measure the speed of the direct motor. Safety gear coupling is installed between the motor and reduction gears to insure the safety to use the equipment.

Cutting support base is a welded case with four-layers, it has four gear rolls inside, including upper, lower spindle and the others are transition gear rolls

Upper spindle has optical-electricityencoder to control the start-stop position of the shear blade in the processing of the cutting.

2.Lubrication

Recycled lubrication is adopted for internal gear and bearing of the shearing machine with dilute oil supplied by outside dilute oil station. Sump lubrication is applied for redactor.