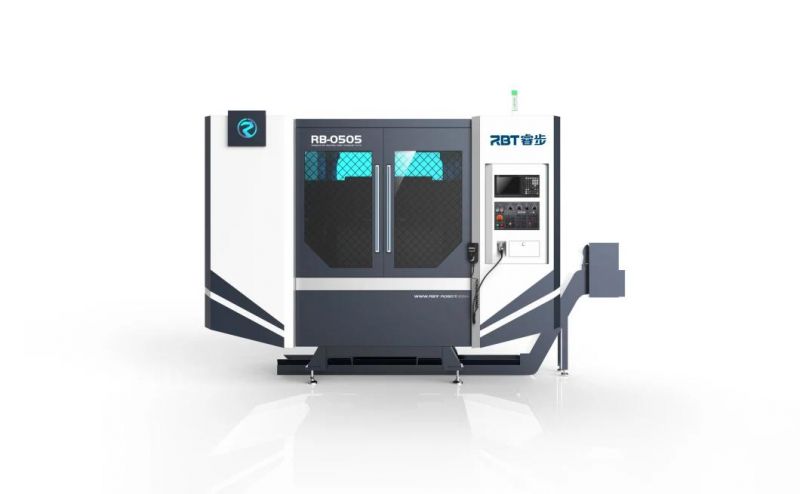

Bathroom Ware and Hardware Multi-Head CNC Engraving and Milling Machine

Fujian RBT Intelligent Equipment Co., Ltd.- After-sales Service:Technical Support, Online Support, Spare Parts

- Warranty:One Year

- Certification:ISO, CE

- Condition:New

- Voltage:380V

- Application:Metal Tube

Base Info

- Model NO.:RB-F3-0505-Z04-8

- Number of Spindle:8

- Control System:Syntec,Mitsubishi,Fanuc

- Total Power:55kw

- Spindle Power:5.5kw

- Weight:8t

- X Axis Stroke:500mm

- Y Axis Stroke:500mm

- Z Axis Stroke:400mm

- Maximum Speed of Three-Axis Machining:15m,Min

- Positioning Accuracy:+,- 0.01,300mm

- Repeat Accuracy:+,- 0.01,300mm

- Applicable Industries:Bathroom Ware (Eg. Faucet), Hardware, Casting

- OEM:Machine Can Be Customized as Required

- Lead Time:15days

- Function:Engraving and Milling Machine

- Transport Package:Export Safety Packing (Customized Packing)

- Specification:L3380*W2260*H2410mm

- Trademark:RBT

- Origin:Quanzhou, China

- Production Capacity:200set,Month

Description

Basic Info.

Model NO. RB-F3-0505-Z04-8 Number of Spindle 8 Control System Syntec/Mitsubishi/Fanuc Total Power 55kw Spindle Power 5.5kw Weight 8t X Axis Stroke 500mm Y Axis Stroke 500mm Z Axis Stroke 400mm Maximum Speed of Three-Axis Machining 15m/Min Positioning Accuracy +/- 0.01/300mm Repeat Accuracy +/- 0.01/300mm Applicable Industries Bathroom Ware (Eg. Faucet), Hardware, Casting OEM Machine Can Be Customized as Required Lead Time 15days Function Engraving and Milling Machine Transport Package Export Safety Packing (Customized Packing) Specification L3380*W2260*H2410mm Trademark RBT Origin Quanzhou, China Production Capacity 200set/MonthProduct Description

Bathroom Ware and Hardware Multi-Head CNC Engraving and Milling Machine

Parameters

Machine Feature

1. The overall body has high strength, annealing and aging treatment after welding, the overall stability of the machine is good, and the accuracy is stable and reliable.

2. Constant and high speed motorized spindle (maximum speed 24000 RPM), high precision, good reliability.

3. Adopt high-precision grinding ball screw rod.

4. Direct coupling connection, transmission rigid, high precision and stability.

4. HIWIN sliding rail from Taiwan is adopted to ensure high precision of machine movement.

5. Adopt timing and quantitative automatic centralized oil supply lubrication system to ensure that any lubricating part can be fully lubricated.

6. Taiwan SYNTEC CNC control system, humanized man-machine operation interface, safety specifications, convenient operation.

7.Nitrogen balance system is used in z-axis of machine to ensure stable and smooth operation.

Application

Suitable for the surface peeling of the bathroom ware (eg. faucet), hardware, casting pieces, car accessory, lock, door knob, jewelry.

1.Plastic film packaging and put in plywood wooden cases or according to customer's requirements.

2.Shipping : Container transport.

FAQ

Q1. Where is your factory located ? How can I visit it ?

A : Our factory is located in Quanzhou city,Fujian province,China. You can fly to Jinjiang or Xiamen air port, we will pick you up.

Q2. Are you produce polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings. Usually one machine have different molds and fixtures like metal polishing machine,die casting machine.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce or the spare parts.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: How is your development ability?

A: We have a strong engineer team to support the drawing, technology proposal, test and certification; We can customize the machine per customer requirement.