Piercer Mill Plug for Piercing Rolling Mill to Produce Seamless Steel Tubes and Pipes

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Cast Steel

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Application Range:Piercer Mill,Plug Bar Assembly

- Transport Package:Woodern Case

- Specification:Cast steel, 35CrMo, H13, 20CrNi4 etc.

- Trademark:FANGLE

- Origin:China

- Production Capacity:30000tons,Year

Description

Basic Info.

Model NO. as the drawing Application Range Piercer Mill,Plug Bar Assembly Transport Package Woodern Case Specification Cast steel, 35CrMo, H13, 20CrNi4 etc. Trademark FANGLE Origin China Production Capacity 30000tons/YearProduct Description

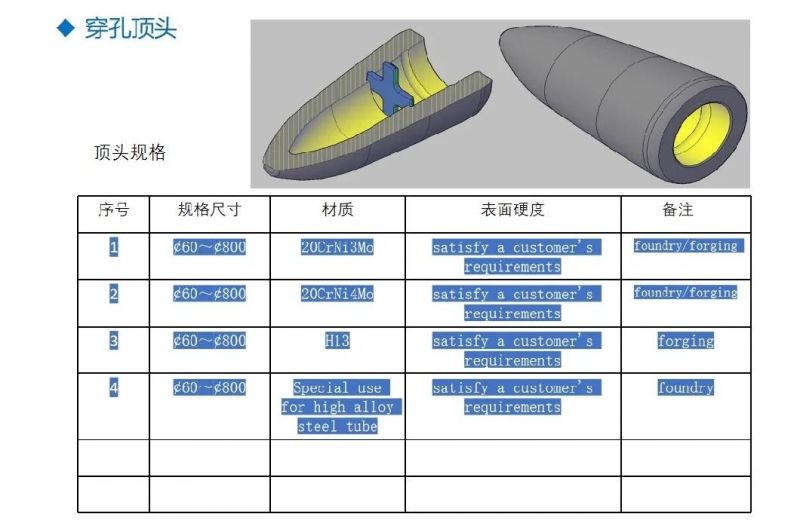

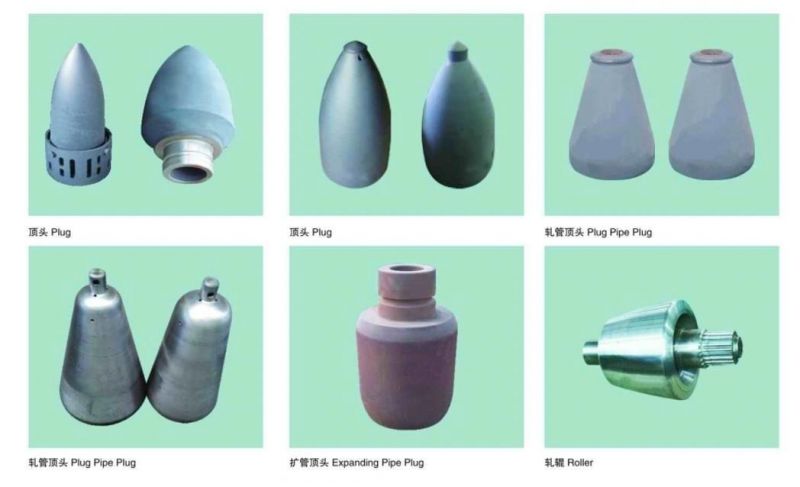

Piercering Mill Plug for Cross Rolling Piercer

Brief Description

Piercing Mill plugs are the wearing part of piercing mill in the production of seamless tubes and pipes.

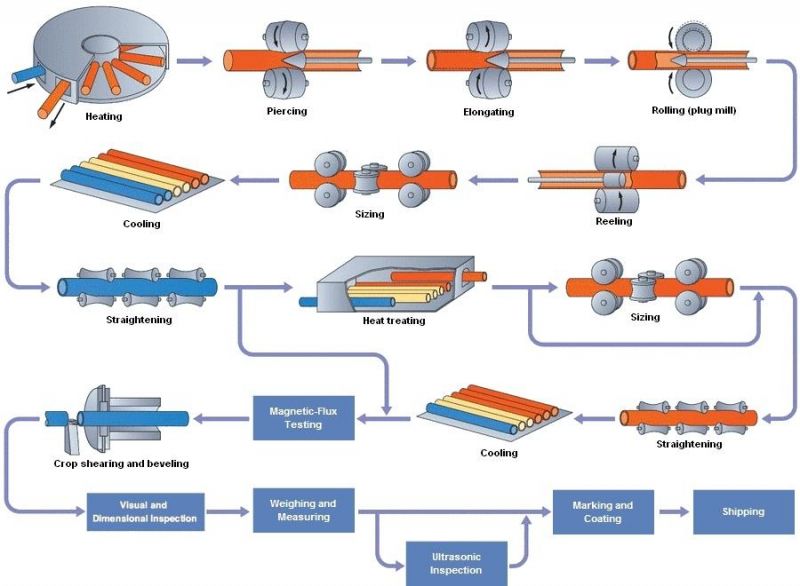

Plug Mill Process, a solid round (billet) is used. It is uniformly heated in the rotary hearth heating furnace and then pierced by a Mannesmann piercer. The pierced billet or hollow shell is rollreduced in outside diameter and wall thickness. The rolled tube simultaneously burnished inside and outside by a reeling machine. The reeled tube is then sized by a sizing mill to the specified dimensions. From this step the tube goes through the straightener. This process completes the hot working of the tube. The tube (referred to as a mother tube) after finishing and inspection, becomes a finished product.

We can produce plugs for all kinds of pipes, carbon steel pipes, alloy steel pipes and stainless steel pipes.

Material: H13,35CrMo,20CrNi4

Surface Treatment: Nitriding oxidation