PVD Vacuum Deposition Metallizing Evaporation Coating Equipment

Ningbo Danko Vacuum Technology Co., Ltd.- Type:Coating Production Line

- Coating:Vacuum Coating

- Substrate:Plastic Materials

- Certification:CE, ISO, TUV

- Condition:New

- Structure Type:Vertical, Double Door

Base Info

- Model NO.:DK

- Coating Film:Aluminum, Chrome, Copper

- Machine Type:PVD System Thin Film Depostition Machine

- Substrate Materials:Glass Diamond

- Parts:Pump, Sealed Ring

- Application 1:Plastic Buttons

- Application 2:Hells

- Working Life:About 10 Years

- After Service:24h, Remote Guidance

- Maintenance:Easy

- Transport Package:Wood Case, Container

- Specification:1800mm*1800mm

- Trademark:DK

- Origin:Ningbo, China

- HS Code:8479899990

- Production Capacity:1000 Sets ,Year

Description

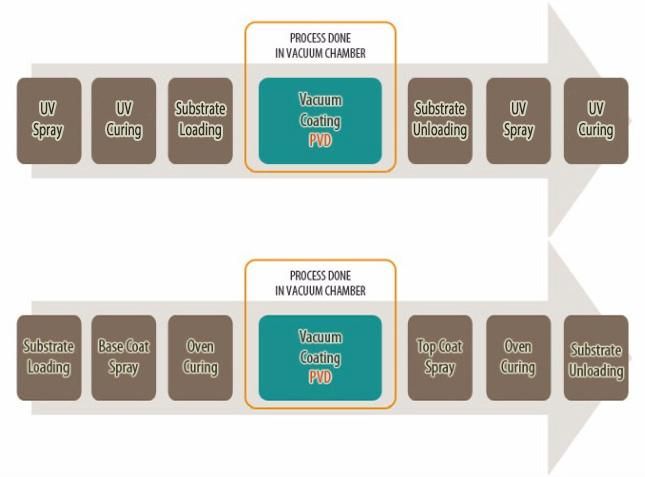

Process

Application

A. Disposable tableware, such as fork and spoon

B. Plastic Artworks, such as Christmas ball

C. Clothing Accessories, such as buttons, zippers

D. Shoe Materials, such as heels

E. Fittings, such as fan button, toys, phone shell, cosmetic bottle and cap

F. Glass jewelry, glass diamond, rhinestone,

G. Car logo, car inner decoration parts

F. Other plastic products

Advantages

A. Fast to film forming, with high deposition speed;

B. Beautiful Color, well distributed

C. Without any gas or liquid wasted

D. Working stably with good vacuum performance

E. Customized processing services

F. High Standards to control quality

Configurations

A. Pumps:

Mechanical pump + roots pump + diffusion pump + holding pump (or optional: cryogenic pump, cryogenic pump system)

B. Limited Vacuum: 8*10-4 pa (cleanroom, no-loading)

C. Shaft: 6 / 8 /9 shafts

D. Power Sources: Resistance heating tungsten wire evaporator power supply, high voltage ion bombardment power supply, thyristor power supply

E. Controlled by Manual, Semi-automatic, Full automatic, PLC

Customer visit

Shipment

Workshop

For more details on configurations quotations, please contact us.

Ningbo Danko Vacuum Technology Co.,Ltd

https://dankovac.en.made-in-china.com

Sara