M Shaped Roll Forming Machine (YX55-100)

Zhangjiagang City Saibo Science & Technology Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Electric

- Feature:High Efficiency

- Certification:ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:YX55-100

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Color:Blue and Yellow

- Transport Package:no packing

- Specification:CE SGS

- Trademark:SAIBO

- Origin:Jiangsu, China

- HS Code:84552210

- Production Capacity:300 units,year

Description

Basic Info.

Model NO. YX55-100 Customized Customized Advantage Easy to Maintenance Condition New Color Blue and Yellow Transport Package no packing Specification CE SGS Trademark SAIBO Origin Jiangsu, China HS Code 84552210 Production Capacity 300 units/yearProduct Description

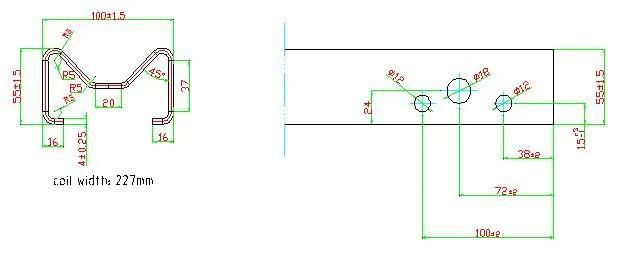

Profile drawing:

Details of each composition

A: Roll forming main machine

1: Coil width: 247mm

2: Working speed: 12m/min

3: Roll station: 15 stations

4: Material of roller: Gcr15 forge steel, polished and coated with hard chrome HRC58-60

5: Material of main shaft: 45forge steel diameter roller: 100mm

6: Main power: 37kw

7: Forming thickness: 3mm_4.5mm galvanized steel or metal sheet

8: Transmission: By gear (surface of the gear HRC 50-55)

9: Dimension of the body machine: : 11000× 1000× 1200mm

10: Weight of machine: About 10000kg

B: Cutting system

(1)Machine adopt hydraulic after cutting.

(2)Cutting after forming: Cut the sheet after roll forming to required length

(3)Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

(4)Material of blade: CR12with heat treatment

(5)Length measuring: Automatic length measuring

(6)Tolerance of length: 3m +/- 1.5mm

C: Punching system

1: Base on customer profile this machine need one punching unit

2: Machine will adopt hydraulic pre-punching

3: Punching mould material: Cr12

4: Punching pressure: 20Mpa

5: Punching distance is controlled by PLC control system

D: PLC control system Panasonic

(1)Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase

(2)Automatic length measurement:

(3)Automatic quantity measurement

(4)Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved

(5)Length inaccuracy can be amended easily.

(6). Control panel: Button-type switch and touch screen

(7)Unit of length: Millimeter (switched on the control panel)

E: Hydraulic station

1: Hydraulic station power: 5.5kw

2: Hydraulic pressure: 20Mpa