Track Roller Ball Bearings CNC Machinery Part

Dongguan Guanchuang Precision Machinery Co., Ltd.- Condition:New

- Certification:CE, RoHS, ISO9001

- Standard:DIN, ASTM, GB, BS

- Customized:Customized

- Material:Metal

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Base Info

- Model NO.:GC20275

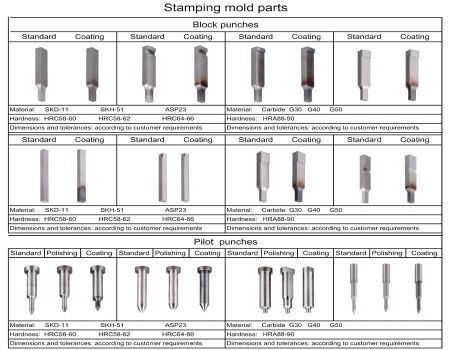

- Surface Treatment:Anodizing,Plating,Polishing,Blacken,Sand Blast

- Aluminum Material:6061,6063,7075,5050

- Tolerance:+,-0.005mm

- Model No.:CNC Machine Parts

- Drawing File:STP,Pdf,Pic

- MOQ:1 PCS

- Bronze Material:C51000,C52100,C54400

- Stainless Steel:Ss201,Ss303,SS304,SS316

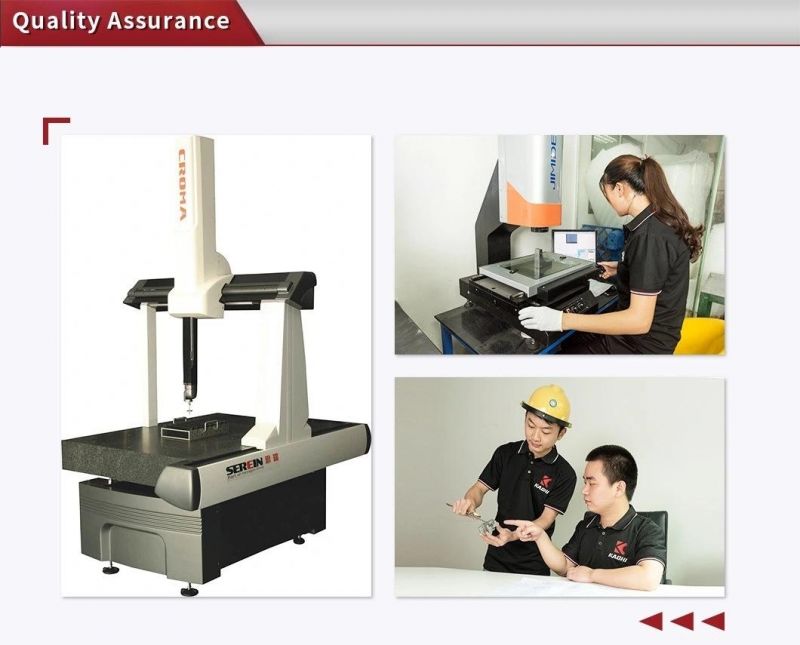

- Quality:100% Inspection on Critical Dimensions

- Delivery Date:Short

- Transport Package:Carton Box, Wooden Box

- Specification:Follow client requirements

- Trademark:OEM

- Origin:Dongguan, China

- HS Code:847990909

- Production Capacity:2000000

Description

1 Series LR rollers are also called CAM ROLLERS, can be used in the heavy loads track or used as an idler wheel. They are widely used in the particular application that the friction should be reduced.

2 The outer diameter surface of rollers is shaped to the crowned runner surface with R500 (suffix U), so make the stresses well when rollers working.

3 Rollers take the internal structure design of deep groove ball bearings or double row angular contact ball bearings and have a particularly thick-walled outer ring, so the rollers can accommodate higher loads.

4 Rollers are made of the high-quality bearing steel, processed by heat treatment and precision grind, and are filled with a long service life, high -grade and multi-purposes grease. Rollers take the metal shield (suffix KDD) or rubble seal (suffix NPP) to prevent the dust.

Being cam rollers with crowned runner surface R500, make its stresses in well-distributed between rollers and track when working, thus the stresses centralization are avoided, the friction resistance are reduced and the service life of rollers have been improved a lot. Most of the double row cam rollers can be relubricated through the filling hole on the inner ring to adapt the adverse working conditions.

2. Easy installation

After rollers assembled the concentric or eccentric pivot, installation can be made convenient. To adjust the eccentric one's eccentricity, the rollers can get the fitting preload.

3. Smooth running, minimum error

Besides we produce the series LR cam rollers according to the standard of rolling bearings, we also make the strict control on the rotary accuracy of outer ring in order to meet special working mode that inner ring is fixed while outer ring running.

About us

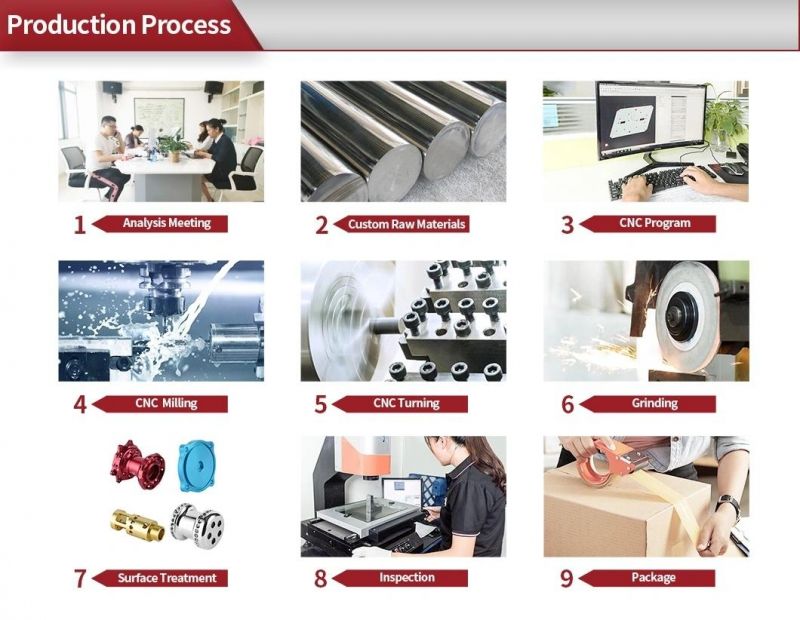

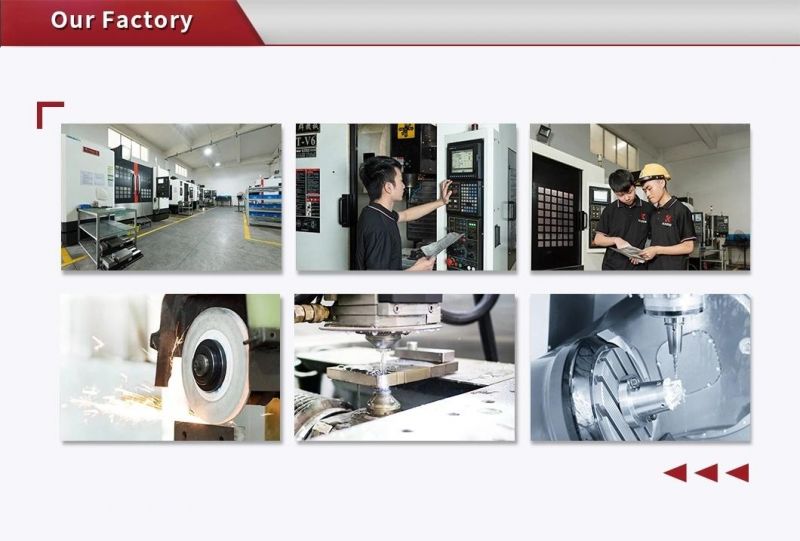

Dongguan Guanchuang Precision Machinery Co., Ltd. specializes in machining all sorts of high precision machinery components, precision CNC metal and non-metal machining parts with various surface treatments, which apply to packaging machines, printing machines, assembly machinery, electronic packing facilities, metal processing facilities, food machinery and pharmaceutical industry, etc. We have been in CNC precision machining industry for over 10 years. We can manufacture all kinds of high precision machine parts with good quality and favorable prices.

We are a reliable and experienced machining company, manufacturing many kinds of machinery parts&Metal components, including CNC machining parts, turning parts, CNC Milling parts, auto lathe part, casting&forging parts for a wide of variety of industries.

We design, manufacture and assemble all kinds of different metal parts according to customers Designs or drawings and requirements.

Specially, we are in line of hydraulic cylinder component parts, construction machinery parts, Auto parts, Agricultural Machinery Parts, Electric power fitting, hot die forging part, metal glass seal etc.

And most of our parts were exported to Europe and north America.

After ten years of development, we know how to use our equipment and knowledge to do the good job. Our primary goal is to achieve high quality levels that provide our customers with safe and reliable products with on time delivery at competitive prices meeting or exceeding their needs.

Our Engineering can help you with your ideas, drawings and products from initial prototype, right through to production and deliver of precision components in various materials, such as: Mild steel, copper, , aluminum, stainless steel, steel alloys, brass and plastics.

Our company supplies different kinds of products. High quality and favorable price. We're pleased to get your Inquiry and we will come back to you as soon as possible. We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers' requirements" for the management and "zero defect, zero complaints" as the quality objective. To improve our service, we provide products with good quality and reasonable price.

Features of CNC parts

1. Precision CNC parts strictly according to customers' drawing,packing and quality request

2. Tolerance: Can be kept in +/-0.005mm

3. 100% inspection during production to ensure the quality

4. Experienced technology engineers and well trained workers

5. Fast and timely delivery. Speedy & professional service

6. Provide customer professional suggestion while in the process of customer designing to save cost.

7. Quality assurance in accordance with ISO9001

Description:Material

C27200(CuZn37), C28000(CuZn40) etc.

coating, e-coating, electrophoresis, Delta Seal, Delta Tone

and feedback ASAP

FAQ

1.How long and how can I get quotation from your company?

We will reply you in two hours if getting detailed information during working days.

In order to quote you as soon as possible, please provide us the following information together with your inquiry.

1). Detailed drawings (CAD/PDF/DWG/IGS/STEP/JPG)

2). Materials required

3). Surface treatment

4). Quantity (per order/per month/annual)

5). Any special demands or requirements, such as packing, labels,delivery,etc.

2.Can I get samples for testing?

We can offer free samples for small existing parts, but for big and high-value products, samples will be charged.

3.How about the payment terms?

For new customers, we prefer to use T/T in advance. We can accept L/C, D/P for old customers.

4.If I need urgent delivery, can you help?

Of course! You need to tell us the delivery time when placing the order, and we will do our best to adjust the production schedule.

5.How about the transportation?

You can choose any mode of transportation you need, sea delivery, air delivery or express delivery.

6.How about the quality guarantee?

We will make 100% inspection before packing and delivery and make sure the products 100% meet your requirements . If there is any problems during using, please tell us anytime, we will reply you in time

7.Can we sign NDA?

Sure. We never divulge any customer's information to anyone else.