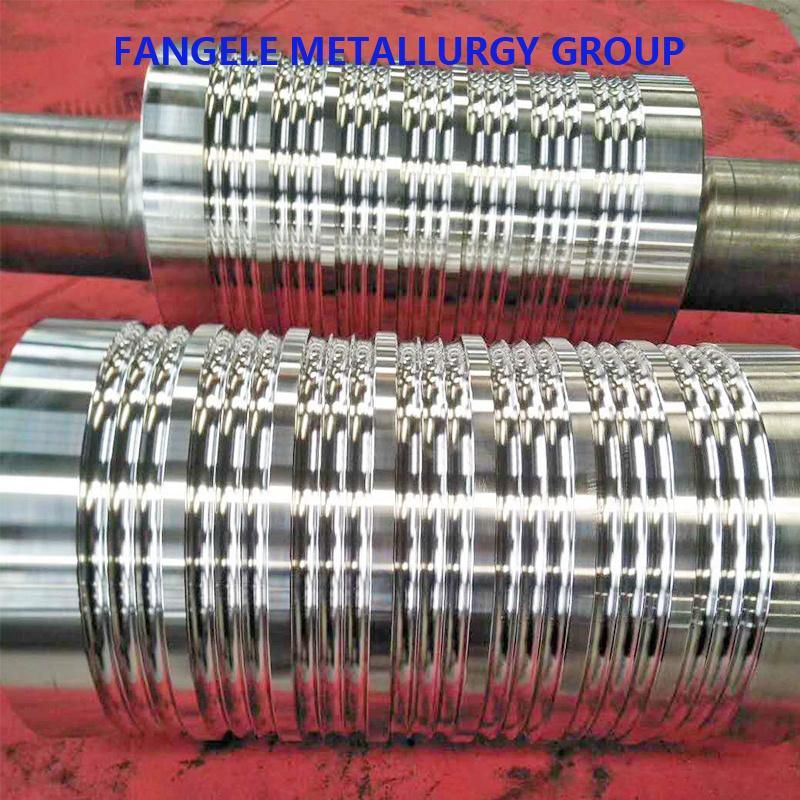

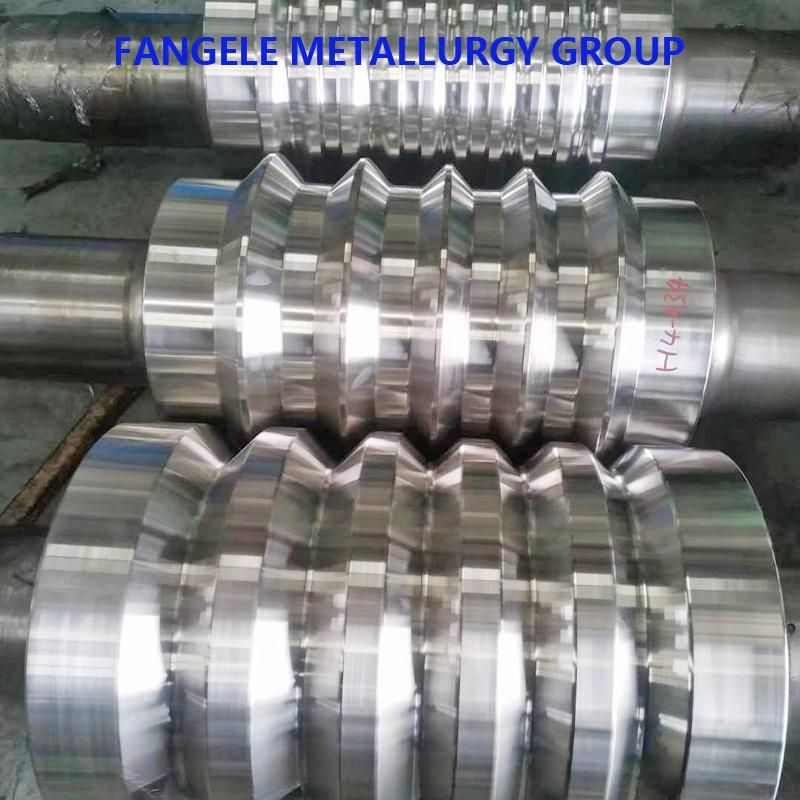

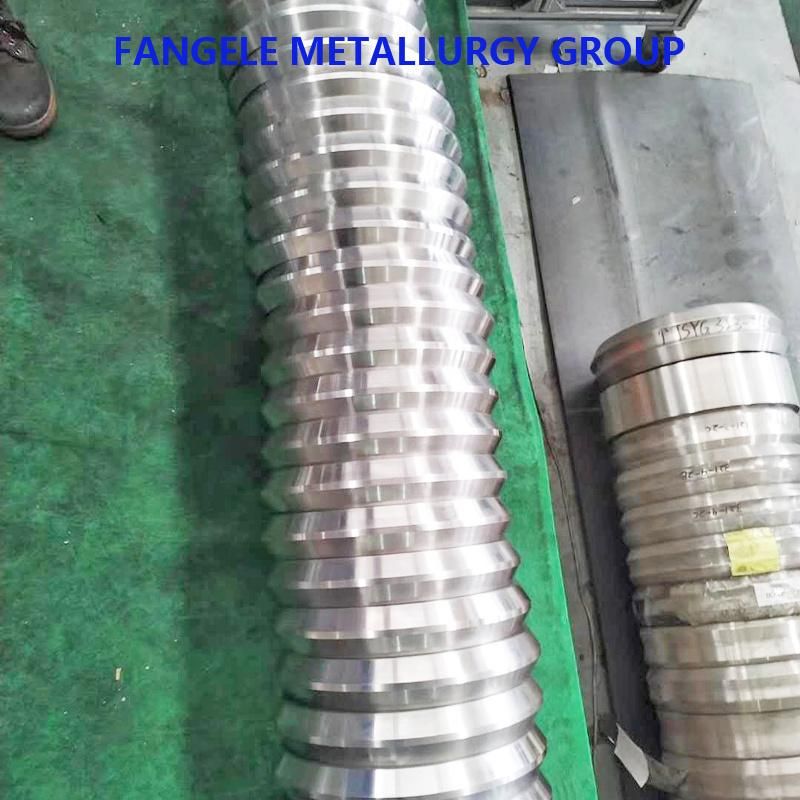

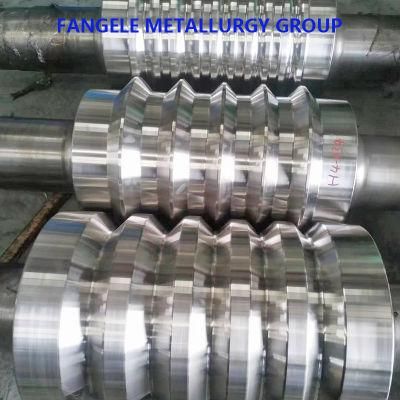

Centrifugal Casting High Speed Steel Roller and Roller Ring for Rebars and Rod Production

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, GOST, GB

- Customized:Customized

- Material:Stainless Steel

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Apllication Range:Rod Mill, Rebars Mill

- Transport Package:Seaworthy Package

- Specification:as the drawing

- Trademark:FANGLE

- Origin:China

- Production Capacity:50000 Tons,Year

Description

Basic Info.

Model NO. as the drawing Apllication Range Rod Mill, Rebars Mill Transport Package Seaworthy Package Specification as the drawing Trademark FANGLE Origin China Production Capacity 50000 Tons/YearProduct Description

Centrifugal Casting High Speed Steel Roller and Roller Ring for Rebars and Rod ProductionDescription

Centrifugal casting high speed steel roller is the most important tool in the production of rod and rebars.The high-speed steel roller material contains high vanadium, chromium, molybdenum,niobium and other alloy elements. The type of carbide in the roll structure is mainly MC type and M2C type. The carbide has high hardness and good wear resistance. Compared with the traditional nodular iron roll and high nickel chromium roll, the single groove(times) passing steel is high, which saves the roll changing time, improves the rolling operation rate, reduces the roll consumption and reduces the production cost and improves the comprehension benefit of the factory.

The core of centrifugal casting high speed steel roll is made of alloy ductile iron, the strength of roll neck is high.

Application scope of the high speed steel

The high speed steel roll produced by our company is widely used in:

The finished stand (high speed steel roll),

The front stand (high speed steel roll),

The slitting stand (slitting high speed steel roll) and the pre slitting stand (slitting high speed steel roll) of the bar rolling mill.

Pre finishing mill of high speed wire rod mill.

Finishing mill of hot strip mill.Spring flat steel mill finishing stand and small section steel mills such as angle steel and channel steel.

Main chemical composition:

composition | C | Si | Mn | Cr | Ni |

proportion(%) | 1.5-2.2 | 0.3-1.0 | 0.4-1.2 | 3.0-8.0 | 0.0-1.5 |

composition | Mo | V | W | P | S |

proportion(%) | 2.0-8.0 | 2.0-9.0 | 0.0-8.0 | ≤0.03 | ≤0.03 |

Inspection rules:

a. Inspect the dimension and surface quality of each part one by one;

b. Carry out three times of ultrasonic flaw detection one by one;

c. Carry out hardness test one by one;

d. The effective hardened layer depth of the roller body is guaranteed by the manufacturing process.

Products show