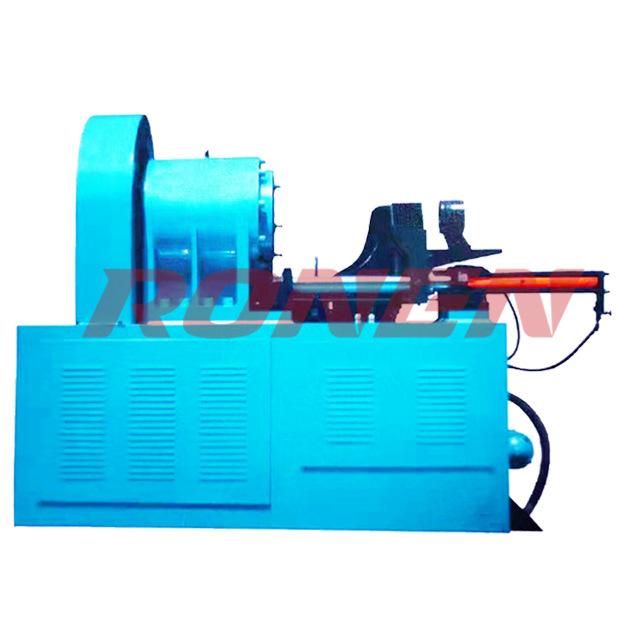

Low Noise Conical Shape Steel Pipe End Shrinking Machine Pipe Taper Reducing Machine

Beijing Ron-En Machinery & Integration Co., Ltd.- After-sales Service:Provided

- Type:Swaging or Forging Machine

- Forging Forming Method:Mold Forging

- Power Source:Electric

- Feature:Automation

- Certification:ISO9001, CE

Base Info

- Model NO.:Ronen

- Warranty:12 Months

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Product Name:Manual Pipe Tapering Machine

- Control System:PLC

- Power Souce:Electric

- Core Components:Motor, PLC, Engine

- Processing Scope:150-160

- Multiple Mold:Tube Contraction, Expansion and Blunting

- Delivery Time:Delivery on Time, Without Delay

- After Sales Service:Provide Solutions Within 24 Hours

- Price:Factory Direct Supply Price

- Function:Pipe Reduce Machine

- Weight (Kg):2000

- Raw Material:Tube

- Color:Blue, White or as You Want

- Weight:1000-2500kg

- Voltage:220V,380V,415V,440V,Customized

- Transport Package:Wooden Case or as You Want

- Specification:Depends on the different model

- Trademark:RONEN

- Origin:Hebei, China

- Production Capacity:6000PCS,Year

Description

Pipe Swaging Machine ( Automatic or Manual)

Pipe Swaging Machine ( Automatic or Manual)Equipment Feature

1.PLC control, hydraulic drive, stable operation.

2.The mobile type pedal switch has functions of automation, instant stop and instant stop continuing, so that the safety is high.

3.Multiple processing modes such as tube contraction, tube expansion and tube blunting

4.The die is conveniently changed to facilitate the elastic production.

5.The cold forging method forging fine and drawing out fitting into a cylinder or cone

6.Closed circuit circulating lubrication system to ensure the normal operation of the machine for a long time.

7.Preparation reasonable mould, machining bright tact.

8.The workpiece forming time is short, high efficiency.

Ronen Group Exhibition

Certifications

Packing and Shipping

Q: Are you manufacturer?

A:Yes, We are manufacturer.

Q: How to order?

A:Please send us your inquiry by email, send message through Alibaba , Wechat, Whatsapp or others as you want.

Q: What are the payment terms?

A: Pattern :we can accept T/T,Western Union ,Money Gram.

Q: What is the whole business flow cooperation with us?

A: 1.Firstly,send your inquiry to us, make us have learned your requirement

2.We will be drawing a proforma invoice according to your requirement ,and start production after you finished to pay 30% deposit.

3.All of the goods, packing details will be send to buyer after finished production. We will arrange shipment and the buyer finished to pay the balance.

Not only the Good Machine, but also the Most Attentive Service

If any doubt,feel free to contact us with no doubt!

RONEN always here for you!!