Professional Glazed Tile Roof and Wall Panel Roll Forming Machine

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

- Feature:Automation

- Certification:CCC, ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:Dx 828

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Mode:828 Glazed Roof Tile Forming Machine

- Auto:Fully Automatic

- Feeding Material:Metal Coil

- Feeding Width:1000mm

- Feeding Thickness:0.25-0.7mm Thickness

- Production Speed:2-6m,Min

- Roll Forming Speed:8-12m,Min

- Control Systerm:PLC Computer Control with Inverter

- Size:6500mm*1500mm*1500mm

- Weight:3.2 Tons

- Transport Package:Waterproof Package

- Specification:CE SGS ISO

- Trademark:DIXIN

- Origin:China, Hebei

- HS Code:84552210

- Production Capacity:50 Sets Per Month

Description

Basic Info.

Model NO. Dx 828 Customized Customized Advantage Easy to Maintenance Condition New Mode 828 Glazed Roof Tile Forming Machine Auto Fully Automatic Feeding Material Metal Coil Feeding Width 1000mm Feeding Thickness 0.25-0.7mm Thickness Production Speed 2-6m/Min Roll Forming Speed 8-12m/Min Control Systerm PLC Computer Control with Inverter Size 6500mm*1500mm*1500mm Weight 3.2 Tons Transport Package Waterproof Package Specification CE SGS ISO Trademark DIXIN Origin China, Hebei HS Code 84552210 Production Capacity 50 Sets Per MonthProduct Description

Professional Glazed Tile roof and wall panel Roll Forming MachineGlazed tile has a beautiful appearance than ordinary colored steel roof . It has different color and types. The machine can be customized by profile drawing .The roof tile roll forming machine can use color steel plate, galvanized steel plate, aluminum zinc plate, thickness range is 0.3-0.6mm.

2. Technique parameters

(1) processing material: Aluzinc/galvanized steel/colored steel coil

(2) material thickness: 0.3-0.8mm

(3) effective width: 828mm

(4) feeding width: 1000mm

(5) main motor power: 4 kw

(6) pump power: 4 kw

(7) shaft diameter: 75 mm

(8) forming steps: 11 steps

(9) roller material: 45# forged steel, with hard chrome plating

(10) main frame: 300h steel

(11) medium plate thickness: 16mm

(12) control systerm: Plc computer control with inverter

(13) power supply: 380v, 3 phase, 60hz or as your requirement

(14) 0veral sized: 6500mm*1500mm*1500mm

Packing size: 5.7m*1.6m*1.5m(l*w*h), 3.2 tons

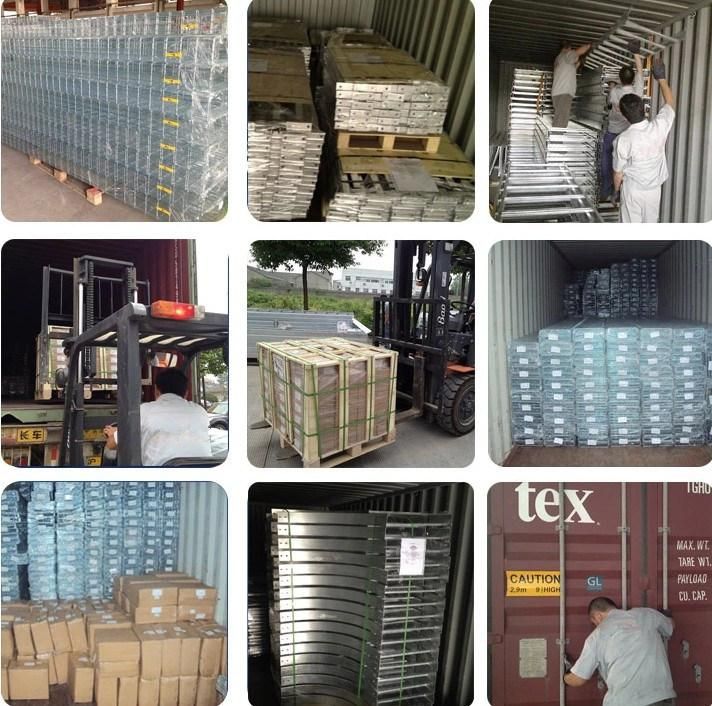

Packaging

1.Packaging Details:Nude,with waterproof cloth and stow-wood. Imported computer control system packed with waterproof cloth and card board.

2.Port:TIANJIN XINGANG PortLead .

3.Time: Shipped in 35 days after payment.

Usually the welding pipe cold roll forming machine can be packed into one 20' feet container or 40' feet container. We have good relationship with the shipping agent. Either you can find the shipping line at your side or we can help you.

Service

1.We have professional team to make different kinds of roll forming machines for our customers,

from designing, processing,assembling, debugging, delivery.

2.we can send our engineer to your site and do the training for your worker. you just only bear the cost for our engineer's air ticket,visa,accommodation,food and transpotaion in your country.

3.You can send your worker to our factory. we will teach them how to operate the machine without training charges.

4.Actually theres another cheap and easy way to choose. Every machine leave our factory with one book of operation manual. You can read through the manaul first ,and get familiar with the machine. Then we can get a video call,and teach you on-line how to operate the machine.

1. Warranty :One year,and we will provide technical support for whole life of the equipment

2. Delivery time: Within 30 days after deposit receipt your payment

3. Guarantee period: 12months free service

4. Installation and training

If buyers visit our factory and check the machine, we will teach you how to install and use the machine

and also train your workers/technician face to face

Without visiting,we will send you user manual and video to teach you to install and operate.

If buyer needs our technician to go to your local factory,please arrange board and lodging and other necessary things

If u have any other question,please contact me any time.