Complete Equipment for Regeneration of Casting Coated Sand

Qingdao Ding Li Machinery Co., Ltd.- After-sales Service:After-Sales Service

- Warranty:One Year Warranty,

- Control Type:PLC

- Customized:Customized

- Condition:New

- Automatic Grade:Automatic

Base Info

- Model NO.:2t,h

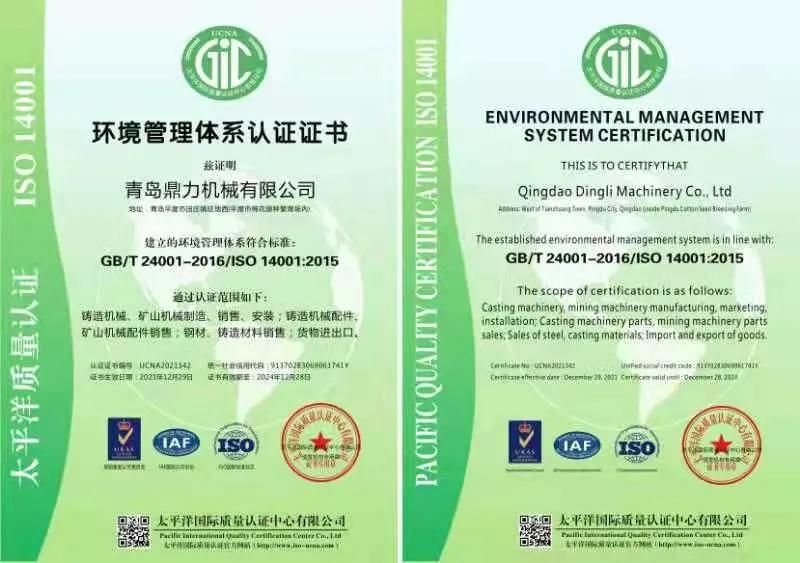

- Certification:CE, RoHS, GS, ISO9001

- Type:Sand Casting

- Transport Package:Custom

- Trademark:DL

- Origin:Qingdao, China

- HS Code:8474802000

- Production Capacity:800

Description

Basic Info.

Model NO. 2t/h Certification CE, RoHS, GS, ISO9001 Type Sand Casting Transport Package Custom Trademark DL Origin Qingdao, China HS Code 8474802000 Production Capacity 800Product Description

Qingdao Dingli machinery Co., Ltd. is located in the beautiful seaside - Qingdao Pingdu, the company set scientific research, manufacturing, installation and commissioning, after-sales service in one. Mainly produces resin sand production line, clay sand production line, coated sand production line equipment, all kinds of sand processing single equipment. The company has advanced casting machinery manufacturing and development technology, the production of products can fully meet the international and domestic market demand. The company has excellent design and development team, skilled construction team, domestic leading casting equipment design concept, perfect after-sales service system, willing to cooperate with the majority of casting enterprises, create a better tomorrow.In line with the "down-to-earth, integrity-based, pay attention to service, continuous innovation" business philosophy, through continuous efforts. With our own efforts and focus on the development of a series of perfect processing equipment, to meet the different needs of the majority of users.

Thermal regeneration of coated sand

The basic principle of thermal regeneration of coated sand is to use old sand pretreatment and boiling type thermal regeneration furnace equipment. First of all, the old sand is broken by vibration and magnetic separation, and then roasted in the boiling regenerative furnace. After sand production, it can be reused by heat preservation, cooling and screening.

The performance of the recycled sand after thermal regeneration is less than 0.3%, the particle size concentration rate is 80%-90%, and the gas generation rate is less than 3mL /g

Boiling resin sand thermal regeneration device:

The wide application of cold core, hot core, shell core and resin sand composite core technology has greatly improved the dimensional accuracy, surface quality and yield of castings, but how to recycle the old sand which is difficult to be recycled by these mechanical methods has been concerned by colleagues in the industry. In recent years, our construction institute, shandong university of China in eastern China's shandong province relevant scientific research personnel cooperation, jointly developed a boiling type resin sand thermal reclamation device, using manufacturer will these industrial waste, waste saves the casting manufacturing costs, and solve the environment pollution from waste sand, at the same time improve the quality of the castings, received a significant social and economic benefits.

1. Process flow and main equipment introduction:

The device is mainly composed of three parts: pre-treatment of old sand, boiling roasting (two national patents have been obtained) and post-treatment of reclaimed sand.

The old sand pretreatment part is composed of magnetic belt separator, vibration crusher, 1# bucket lifting machine and old sand storage bin. The waste sand falls on the magnetic separation belt through the falling grid, and after the separation of sand and iron by the magnetic separation belt pulley, it is added to the vibration crusher, and the sand block is broken into small sand blocks less than 3mm or a single sand grain, which is lifted to the old sand storage bin by the 1# bucket lifting machine.

The boiling roasting part is composed of disc feeder, 2# bucket picker and boiling roaster. The disk feeder under the old sand storage bin gives the old sand evenly and quantitatively, and then lifts it from the 2# bucket lifting machine to the upper part of the furnace and adds it to the furnace by boiling roasting for regeneration.

The post-treatment of reclaimed sand is composed of high efficiency heat exchanger and cooling and lifting unit. The high-temperature reclaimed sand flows into the efficient heat exchanger, which reduces the temperature of the outgoing sand and increases the temperature of the high pressure wind. After heat transfer and cooling, the reclaimed sand is cooled and raised by the cooling elevator before storage, and the preheated high-pressure air is returned to the mixing chamber in the furnace for waste heat utilization.

The main machine of this device is boiling roaster.

Its working principle is that the old sand is rained down after being distributed by the sand separator, preheated by the rising hot gas flow into the boiling chamber through the baffle plate, and the high-temperature gas in the mixing chamber is boiled by several nozzles on the boiling hole plate and roasted the old sand, so that the resin film covered by the sand is burned to achieve the purpose of regeneration. With the continuous addition of the old sand, the roasted sand in the action of the high and low baffle and by a number of "∽" shape movement, to ensure the residence time of the roasted sand in the furnace, so that the resin film fully combustion. The roasted sand is further regenerated by bumping and rubbing each other in boiling. The fine powder in the reclaimed sand is collected by the dust collector through the dust removal pipeline under the action of boiling.

2. Application:

The device has been used in 7 domestic factories, including 2 factories for cast iron coated sand regeneration, 2 factories for cast aluminum coated sand regeneration, 2 factories for cast iron cold core sand regeneration, 1 factory for cast steel coated sand regeneration. Many years of production practice has proved that the roaster is reliable in operation, high thermal efficiency and remarkable in energy saving. The regenerated sand has smaller expansion rate, lower gas generation, more rounded grain shape and better use than the new sand.

| productivity | 2T/H |