Automatic Resin Sand Regeneration Equipment

Qingdao Ding Li Machinery Co., Ltd.- After-sales Service:After-Sales Service

- Warranty:One Year Warranty,

- Control Type:PLC

- Customized:Customized

- Condition:New

- Automatic Grade:Automatic

Base Info

- Model NO.:5t,h

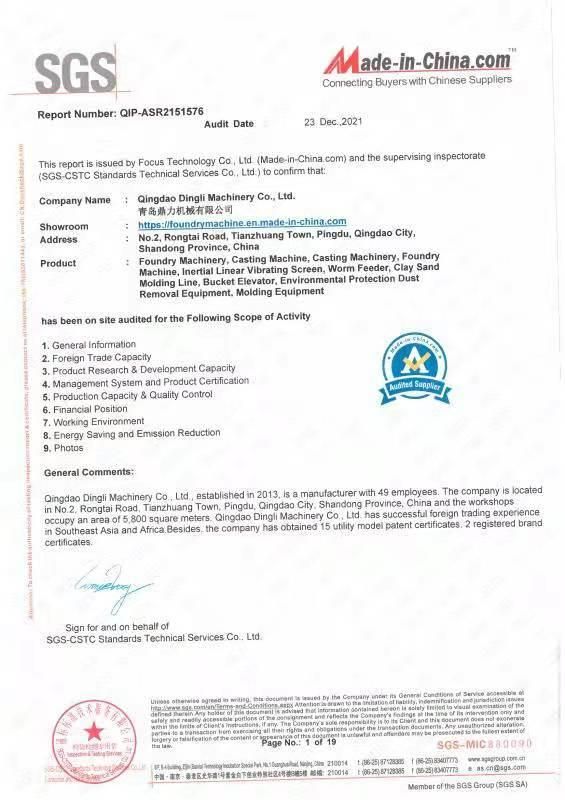

- Certification:CE, RoHS, GS, ISO9001

- Type:Sand Casting

- Transport Package:Custom

- Trademark:DL

- Origin:China

- HS Code:8474802000

- Production Capacity:500

Description

Basic Info.

Model NO. 5t/h Certification CE, RoHS, GS, ISO9001 Type Sand Casting Transport Package Custom Trademark DL Origin China HS Code 8474802000 Production Capacity 500Product Description

Qingdao Dingli machinery Co., Ltd. is located in the beautiful seaside - Qingdao Pingdu, the company set scientific research, manufacturing, installation and commissioning, after-sales service in one. Mainly produces resin sand production line, clay sand production line, coated sand production line equipment, all kinds of sand processing single equipment. The company has advanced casting machinery manufacturing and development technology, the production of products can fully meet the international and domestic market demand. The company has excellent design and development team, skilled construction team, domestic leading casting equipment design concept, perfect after-sales service system, willing to cooperate with the majority of casting enterprises, create a better tomorrow.In line with the "down-to-earth, integrity-based, pay attention to service, continuous innovation" business philosophy, through continuous efforts. With our own efforts and focus on the development of a series of perfect processing equipment, to meet the different needs of the majority of users.

Dingli Machinery Co., LTD., based on years of experience in resin sand production line design and manufacturing, has designed three sets of economic resin sand production lines (resin sand regeneration lines) suitable for small and medium-sized casting workshops: Shallow pit type economic resin sand production line (resin sand regeneration line), the whole resin sand production line equipment only needs shallow pit, especially suitable for the existing small casting workshop using resin sand transformation, easy to move, less investment; ** sets: compact economic resin sand production line, resin sand production line covers an area of less, the production capacity of 2000-5000 tons; Three sets: conventional economic resin sand production line (resin sand regeneration line), investment saving, economic configuration; Economic resin sand line (resin sand regeneration line) is composed of shallow pit multi-functional vibration regeneration, magnetic separator, bucket lifting machine (or dense phase pneumatic conveying), centrifugal rotor regeneration, new sand regeneration combined bucket, double arm continuous sand mixing machine, dust removal system and PLC control system and other equipment. The specific configuration can be adjusted according to the actual situation of users. Resin sand production line (resin sand regeneration line) features: the main equipment technology is perfect, a multi-purpose machine, production line configuration optimization, compact layout; Low investment, quick effect, economical and practical. The production capacity is 3-10t/h, 5-20t/h and 30-80KW of sand regeneration capacity of 1000-5000T casting system. The equipment investment of this resin sand production (regeneration) line is about 200,000 YUAN, covers an area of less than 18m2, and the recycling rate of old sand is more than 95%. The dust emission concentration is less than the national standard 150mg/m3, the line is composed of secondary regeneration (vibration regeneration + centrifugal regeneration), secondary dust removal (low resistance cyclone dust removal + bag dust removal), magnetic separation, transportation, screening, quantification, sand mixing and other equipment. Its characteristics: less investment, one-time investment, lifetime use, fast mounting, excellent performance, the old sand by magnetic separation and two regeneration and full dust removal, high film removal rate, good regeneration effect, continuous sand mixing machine equipped with imported pump, reliable use, low maintenance, good quality of sand mixing.