Znc Spark Erosion EDM Die Sinking Machine D7125 / D7132 / D7140 / D7145 / D7150 / D7160

Tengzhou Wellon Machinery Co., Ltd.- Condition:New

- Certification:CE, RoHS, ISO9001

- Standard:ANSI

- Customized:Customized

- Material:Metal

- Application:Metal Cutting Machine, Metal Processing Machinery Parts

Base Info

- Model NO.:D7125 , D7132 , D7140 , D7145 , D7150 , D7160

- Worktable Size:400*250mm

- Machine Size :1100*1200*2040mm

- Transport Package:Wood Case

- Specification:CE ISO9001

- Trademark:WELLON

- Origin:China

- HS Code:84621090

- Production Capacity:200PCS,Month

Description

Basic Info.

Model NO. D7125 / D7132 / D7140 / D7145 / D7150 / D7160 Worktable Size 400*250mm Machine Size 1100*1200*2040mm Transport Package Wood Case Specification CE ISO9001 Trademark WELLON Origin China HS Code 84621090 Production Capacity 200PCS/MonthProduct Description

Performence Features:

1, Adopt Japan SANYO DC servo motor;

2, Steady safety device, optical sensors, auto answer, fire extinguisher and power cut off;

3, Good machine structure, high rigidity, high precision, adopt V slide design;

4, Adopt HT300 aging treatment casting, keep precision long time;

5, Adopt high quality imported oil pump;

6, Three-axis linear scale;

7, For copper, graphite, steel, on the cavity, and special shape holes machining;

8, Lubrication system uses recovery mode, rail lubrication action at once, and keep the look clean;

9, Equipped with Taiwan IPC configuration, the parameters can automatic set up; LCD display;

10, The new design meets European CE safety standards, can be dustproof, waterproof, anti-interference

and improve the life of electronic board;

Die Sinker Product Description

A. There is automatic A. R. C carbon surveillant device to prevent destroying working piece;

B. Steady circuit of big area electrode;

C. High and low clearance individual circuit;

D. PWM servo system, standard DC servo motor;

E. Synchronous discharge system of high voltage super posited;

F. Square wave and equal energy output;

G. Circuits of super-fine process;

H. Capacity of mirror process (negative pole);

Technical parameter:

| Item | D7125 | D7132 | D7140 | D7145 | D7150 | D7160 |

| Worktable size | 400x250 | 500x200 | 650x400 | 720x450 | 800x500 | 1000x600 |

| Worktable size | 1030x520x320 | 1030x560x320 | 1050x630x410 | 1400x710x410 | 1450x780x500 | 1680x850x580 |

| X axis travel | 250 | 320 | 400 | 450 | 500 | 600 |

| Y axis travel | 150 | 250 | 300 | 350 | 400 | 450 |

| Z axis travel | 240 | 240+240 | 250+250 | 250+250 | 250+300 | 250+350 |

| Distance between electrode and worktable | 400 | 550 | 650 | 680 | 700 | 800 |

| Max. workpiece weight | 250 | 550 | 750 | 800 | 800 | 1000 |

| Max.electrode weight | 50 | 60 | 70 | 80 | 100 | 150 |

| Machine weight | 1100 | 1200 | 1800 | 2000 | 2200 | 3000 |

| Machine size | 1100x1200 x2040 | 1100x1400 x2120 | 1100x1200 x2040 | 1500x1500 x2250 | 1600x1500 x2300 | 1700x1600 x2400 |

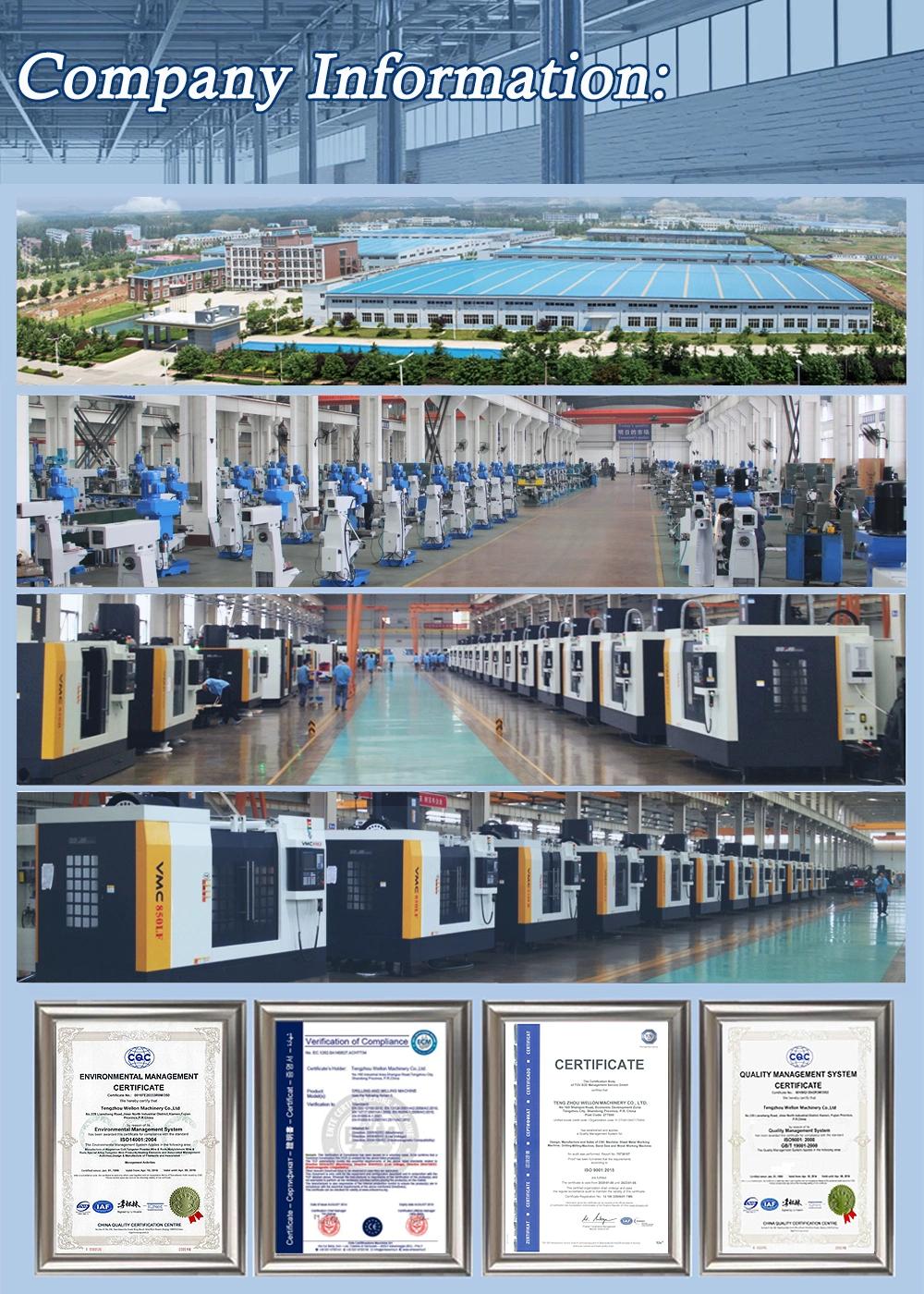

Company Information: