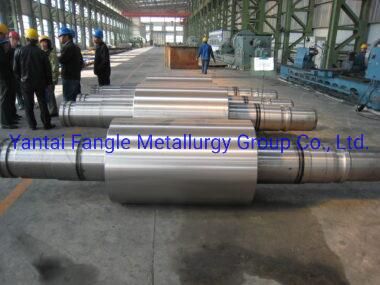

Casted Work Roll with High Cr 7% for Producing Hot Rolled Steel Sheet and Steel Plate

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Application Range:Cold Rolling Mill,Hot Rolling Mill,Sheet Mill,

- Material Spec:Cr3,Cr5 etc

- Production Method:Forged, Cast

- Properties:Wearing Resistance, Good Metallographic Structure

- Hardness:85-102hsd

- Mill Stand Position:Roughing Stand, Prefinishing Stand,Finishing Stand

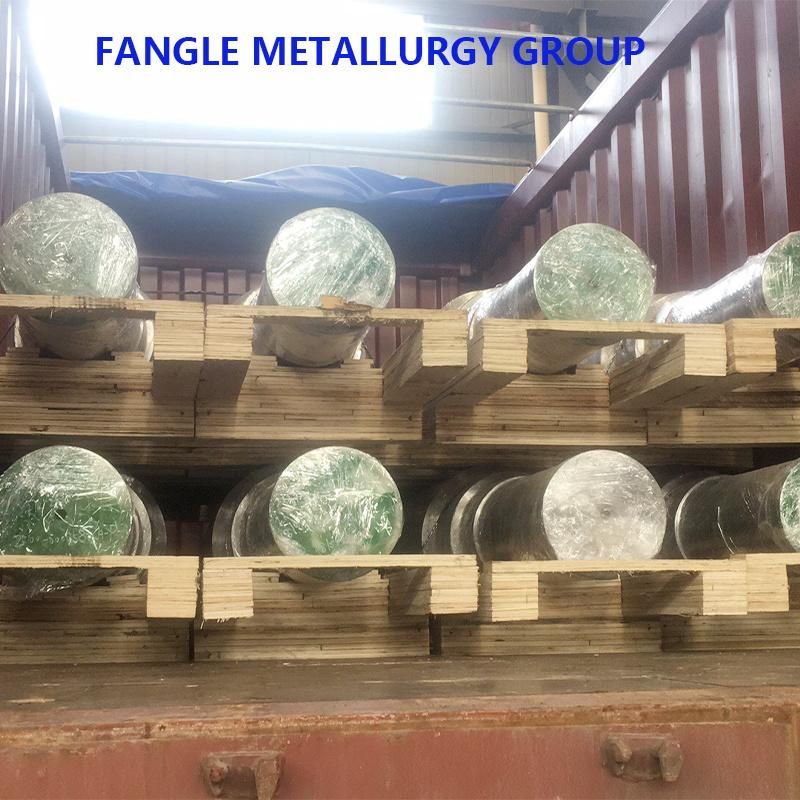

- Transport Package:Woodern Case

- Specification:Export package

- Trademark:FANGLE

- Origin:China

- Production Capacity:6000tons,Year

Description

Neck Tensile StrengthAlloy HSD HSD HSS 1.5~2.2 0.3~1.0 0.4~1.2 N/0~8 N/2~9 3~8 0~1.5 2~8 N 75-95 30-45 ≥400 S-HSS (semi) 0.6~1.2 0.8~1.5 0.5~1.0 N/0~3 N/0.4~3 3~9 0.2~1.2 2~5 N 75-95 30-45 ≥400 HCr Steel 1~1.8 0.4~1.0 0.5~1.0 N/N N/N 8~15 0.5~1.5 1.5~4.5 N 70-85 35-45 ≥400 HCr Iron - A 2.3~3.3 0.3~1.0 0.5~1.2 ≤1.0/N ≤0.5/N 12~15 0.7~1.7 0.7~1.5 0~0.06 60-75 32-45 ≥400/200 HCr Iron - B 2.3~3.3 0.3~1.0 0.5~1.2 ≤1.0/N ≤0.5/N 15~18 0.7~1.7 0.7~1.5 0~0.06 65-80 32-45 ≥400/200 HCr Iron - C 2.3~3.3 0.3~1.0 0.5~1.2 ≤1.0/N ≤0.5/N 18~22 0.7~1.7 1.5~3.0 0~0.06 75-90 32-45 ≥400/200 SGP - A 2.9~3.6 1.4~2.2 0.4~1.0 ≤0.1/N ≤0.03/N 0.1~0.6 1.5~2.0 0.2~0.8 N 45-55 35-55 ≥450 SGP - B 2.9~3.6 1.2~2.0 0.4~1.0 ≤0.1/N ≤0.03/N 0.2~1.0 2.01~2.5 0.2~0.8 N 55-65 35-55 ≥450 SGP - C 2.9~3.6 1.0~2.0 0.4~1.0 ≤0.1/N ≤0.03/N 0.2~1.2 2.51~3.0 0.2~0.8 N 62-72 35-55 ≥450 SGA - A 2.9~3.6 1.2~2.2 0.2~0.8 ≤0.1/N ≤0.03/N 0.2~1.0 3.01~3.5 0.5~1.0 N 55-78 32-45 ≥350 SGA - B 2.9~3.6 1.0~2.0 0.2~0.8 ≤0.1/N ≤0.03/N 0.3~1.5 3.51~4.5 0.5~1.0 N 60-80 32-45 ≥350 ICDP(CrMo) 2.9~3.6 0.6~1.2 0.4~1.2 ≤0.25/N ≤0.08/N 0.6~1.2 N 0.2~0.6 N 50-70 35-55 ≥160 ICDP(NiCrMo)A 2.9~3.6 0.6~1.2 0.4~1.2 ≤0.25/N ≤0.08/N 0.7~1.2 0.5~1.0 0.2~0.6 N 55-72 35-55 ≥160 ICDP(NiCrMo)B 2.9~3.6 0.6~1.2 0.4~1.2 ≤0.25/N ≤0.08/N 0.7~1.2 1.01~2.0 0.2~0.6 N 55-72 35-55 ≥160 ICDP(NiCrMo)C 2.9~3.6 0.6~1.2 0.4~1.2 ≤0.25/N ≤0.05/N 0.7~1.2 2.01~3.0 0.2~1.0 N 65-78 32-45 ≥350 ICDP(NiCrMo)D 2.9~3.6 0.6~1.5 0.4~1.2 ≤1.0/N ≤0.05/N 1.0~2.0 3.01~4.8 0.2~1.0 N 70-83 32-45 ≥350 ICDP(NiCrMo)E 2.9~3.6 0.6~1.5 0.4~1.2 ≤1.0/N ≤0.05/N 1.0~2.0 3.01~4.8 0.2~2.0 0~2.0 77-85 32-45 ≥350 Graphitic Steel A 1.3~1.5 1.3~1.6 0.5~1.0 ≤0.035/N ≤0.030/N 0.4~1.0 N 0.2~0.5 N 36-46 ≤50 ≥500 Graphitic Steel B 1.4~1.6 1.0~1.7 0.6~1.0 ≤0.035/N ≤0.030/N 0.6~1.0 0.2~1.0 0.2~0.5 N 40-50 ≤50 ≥500 Graphitic Steel C 1.5~1.7 0.8~1.5 0.6~1.0 ≤0.035/N ≤0.030/N 0.5~1.5 0.2~1.0 0.2~0.8 N 45-55 ≤50 ≥500 Graphitic Steel D 1.8~2.0 0.8~1.5 0.6~1.0 ≤0.035/N ≤0.030/N 0.5~2.0 0.6~2.0 0.2~0.8 N 50-65 ≤50 ≥500 Cast Steel 60 0.55~0.65 0.2~0.6 0.5~1.0 ≤0.035/N ≤0.030/N 0.8~1.2 0.2~1.5 0.2~0.6 N 35-45 ≤45 ≥600 Cast Steel 65 0.6~0.7 0.2~0.6 0.5~0.8 ≤0.035/N ≤0.030/N 0.8~1.2 0.2~0.5 0.2~0.45 N 35-45 ≤45 ≥600 Cast Steel 70A 0.65~0.75 0.2~0.45 0.9~1.2 ≤0.035/N ≤0.030/N N N N N 35-45 ≤45 ≥600 Cast Steel 70B 0.65~0.75 0.2~0.45 1.4~1.8 ≤0.035/N ≤0.030/N N N N N 35-45 ≤45 ≥600 Cast Steel 70C 0.65~0.75 0.2~0.45 1.4~1.8 ≤0.035/N ≤0.030/N N N 0.2~0.45 N 35-45 ≤45 ≥600 Cast Steel 75A 0.7~0.8 0.2~0.45 0.6~0.9 ≤0.035/N ≤0.030/N 0.75~1.0 N 0.2~0.45 N 35-45 ≤45 ≥600 Cast Steel 75B 0.7~0.8 0.2~0.7 0.7~1.0 ≤0.035/N ≤0.030/N 0.8~1.5 ≥0.2 0.2~0.6 N 35-45 ≤45 ≥600 High Alloy Cr3~Cr5 0.4~0.75 0.3~0.6 0.4~0.8 ≤0.035 ≤0.030 2.5~5.5 0.4~1.0 0.2~0.6 0.01~2 - 34-45 ≥500 Adamite AD140A 1.3~1.5 0.3~0.6 0.7~1.4 ≤0.035/N ≤0.030/N 0.8~1.6 N 0.2~0.6 N 38-48/45-55 ≤50 ≥490 Adamite AD140B 1.3~1.5 0.3~0.6 0.7~1.1 ≤0.035/N ≤0.030/N 0.8~1.2 0.5~1.2 0.2~0.6 N 35-45/40-50 ≤50 ≥490 Adamite AD160A 1.5~1.7 0.3~0.6 0.7~1.1 ≤0.035/N ≤0.030/N 0.8~1.2 N 0.2~0.6 N 40-50 ≤50 ≥490 Adamite AD160B 1.5~1.7 0.3~0.6 0.8~1.3 ≤0.035/N ≤0.030/N 0.8~2.0 ≥0.2 0.2~0.6 N 40-50/50-60 ≤50 ≥490

Table.1 Physical Performances

Package &Delivery:

Certificate:

Customers Visiting: