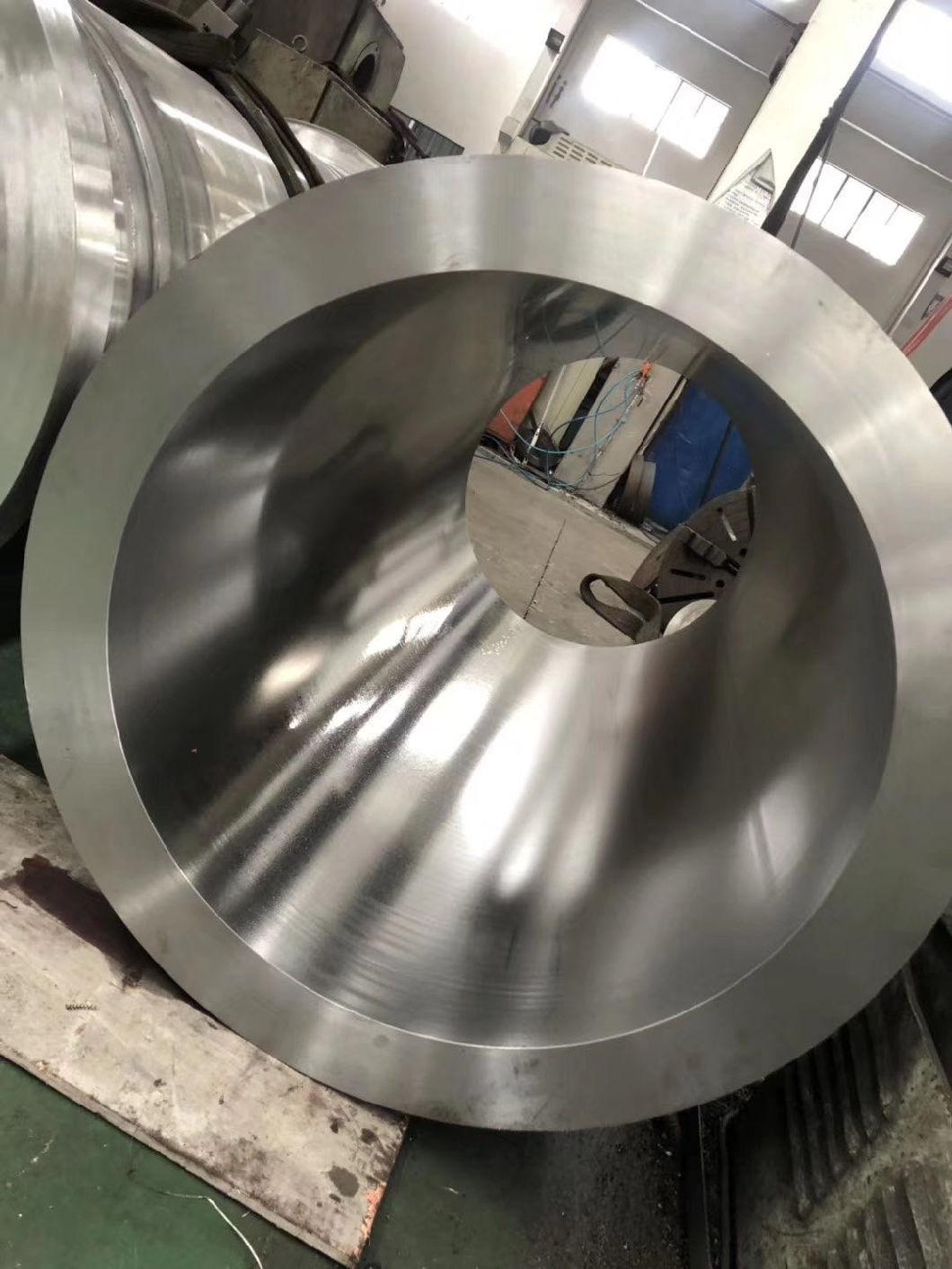

Foundry Large Diameter Centrifugal Casting Bushing Machining Alloy Steel Stainless Steel Drum Shaft for Machine Parts

HENAN QIANGXIN PRECISION MACHINERY CO., LTD.- Condition:New

- Certification:CE, GS, ISO9001

- Standard:DIN, ASTM, GOST, GB, JIS, ANSI, BS

- Customized:Customized

- Material:Stainless Steel

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Base Info

- Model NO.:OEM

- Transport Package:Plywood Case

- Specification:0.5-50000kgs

- Trademark:Qiangxin

- Origin:China

- Production Capacity:200ton-1000ton Per Month

Description

Basic Info.

Model NO. OEM Transport Package Plywood Case Specification 0.5-50000kgs Trademark Qiangxin Origin China Production Capacity 200ton-1000ton Per MonthProduct Description

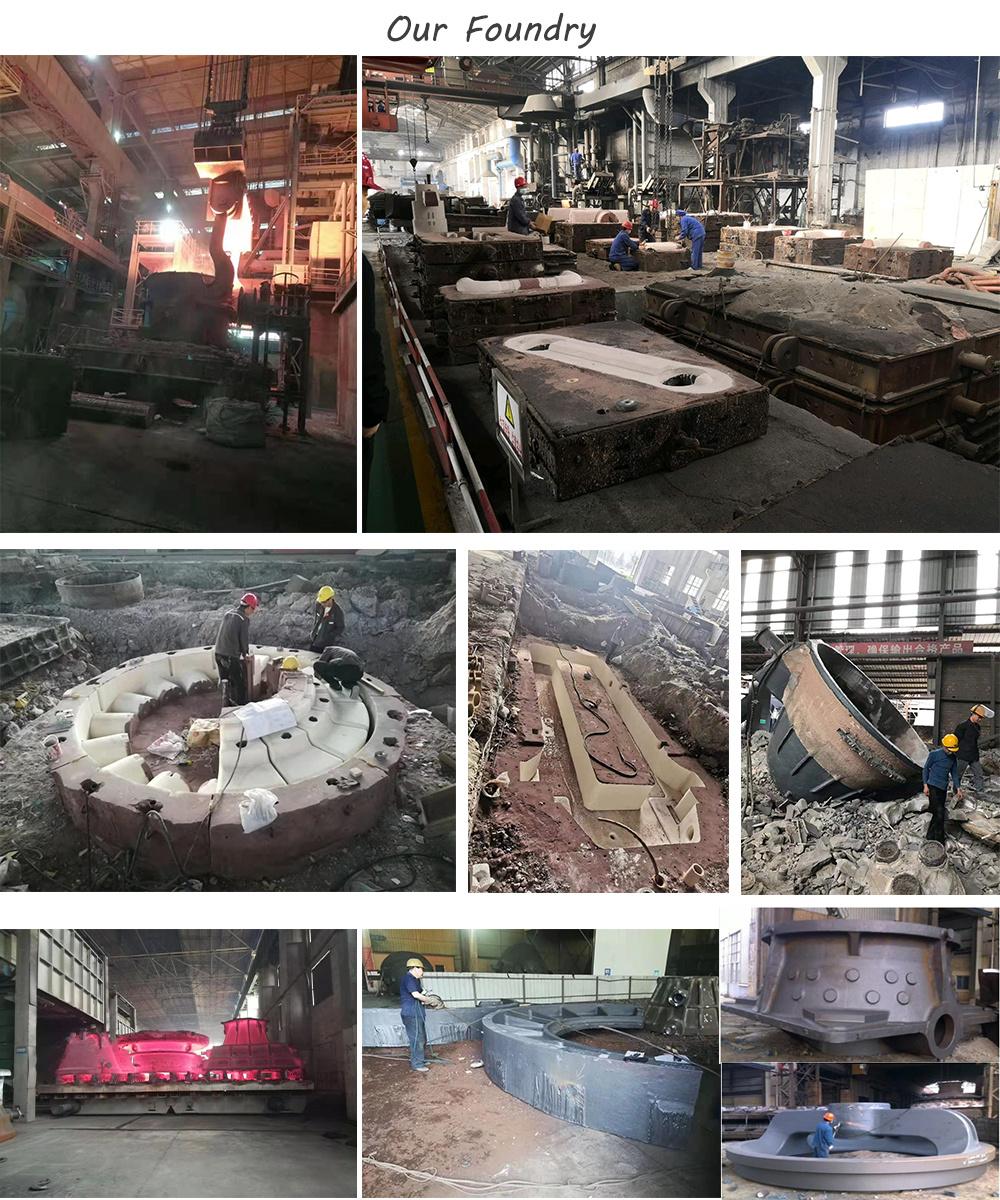

Foundry Centrifugal Casting Process Machining Alloy Steel Stainless Steel Drum Shaft for Machine PartsHenan Qiangxin Precision Machinery Co., Ltd. is a modern foundry enterprise integrating process research and development, production, sales and service, specializing in the production of steel castings, large steel castings, etc. We can provide various types and specifications of ordinary carbon steel castings, alloy steel castings, stainless steel castings, gray iron and ductile iron castings for mining, building materials, forging, metallurgy, road and bridge, hydraulic engineering and other industries

.The company mainly produces mid-to-high quality resin sand castings such as gray iron, ductile iron and alloy cast iron.

Leading products are stainless steel castings, wear-resistant material castings, machine tool castings, valve castings, large generator castings, reducer castings, water pump castings, heavy vehicle parts castings, engineering machinery castings, rail transit castings, wind power castings and other general machinery parts castings, etc.

Product Description

| Specification | Customized, customer required, customer's drawings |

| Material | cast iron, Grey iron, ductile iron, carbon steel, low alloy steel, tool steel, steel, stainless steel, brass, copper, aluminum alloy, zinc etc |

| Process | Sand casting,Coated sand casting,Shell mold casting,Lost foam casting ,V- process,Centrifugal casting,Ceramic Casting,machining,free forging,die forging,pressure forming ,roll forging,precision forging,etc. |

| casting | sand casting,precision casting,investment casting,lost wax casting,die casting,gravity casting |

| machine | lathe,CNC,drilling machine,milling machine,boring machine,planting machine,machining center etc |

| Application | Automobile, agricultural machinery, furniture, construction, home appliances, electronics. |

| surface treatment | powder coating,painting,spraying,electric galvanization,coating,zinc phosphide,impregnation,painting,spray paint,black and blue oxide coating, |

| Inspection equipment | Profile projector,Rockwell hardness tester,Vickers hardness tester roughness tester,air gage,concentricity tester,universial microscope,CMM,digital caliper and etc. |

| Production Usage | Auto parts,train parts,mining accessories,engineering machinery parts,valves,pipe fittings,construction machinery and furniture accessories,agricultural machinery parts |

| Remark | (1)Any RFQ, Please feel free to send your drawings(CAD/PDF)for your quotation. (2)All parts are not in stock, customized only! |

Factory

Certifications

FAQ

1.How can I get the quotation?

Please give us your drawing,quantity,weight and material of the product.

2.If you don't have the drawing,can you make drawing for me? Yes,we are able to make the drawing of your sample duplicate the sample.

3.When can I get the sample and your main order time? Sample time: 35-40 days after start to make mold. Order time: 35-40 days, the accurate time depends on product.

4.What is your payment method? Tooling:100% T/T advanced Order time:50% deposit,50%to be paid before shipment.

5.Which kind of file format you can read? PDF, IGS, DWG, STEP, MAX

6.What is your surface treatment? Including: powder coating, sand blasting, painting, polishing, acid pickling, anodizing, enamel, zinc plating, hot-dip galvanizing, electrophoresis, chrome plating.

7.What is your way of packing? Normally we pack goods according to customers' requirements.