Automatic Cold Heading Forging Machine Bolt Making for Various Size & Type Screws

Xuchang Hongshuo Machinery Co., Ltd.- Forging Forming Method:Mold Forging

- Power Source:Electric

Base Info

- Model NO.:M4-40B M4-40D M5-40B M5-60B M5-80B M5-90B M5-120B

- Feature:Automation

- Certification:ISO9001, CE

- Warranty:24 Months

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Transport Package:Wooden Case or Suitable for Sea Shipping

- Specification:To make different size and type of screws

- Trademark:Hongshuo

- Origin:China

- HS Code:8462991000

- Production Capacity:300 Sets Per Month

Description

Basic Info.

Model NO. M4-40B M4-40D M5-40B M5-60B M5-80B M5-90B M5-120B Feature Automation Certification ISO9001, CE Warranty 24 Months Customized Customized Advantage Use Widely Condition New Transport Package Wooden Case or Suitable for Sea Shipping Specification To make different size and type of screws Trademark Hongshuo Origin China HS Code 8462991000 Production Capacity 300 Sets Per MonthProduct Description

Automatic Cold Heading Forging Machine Bolt Making For Various Size & Type Screws

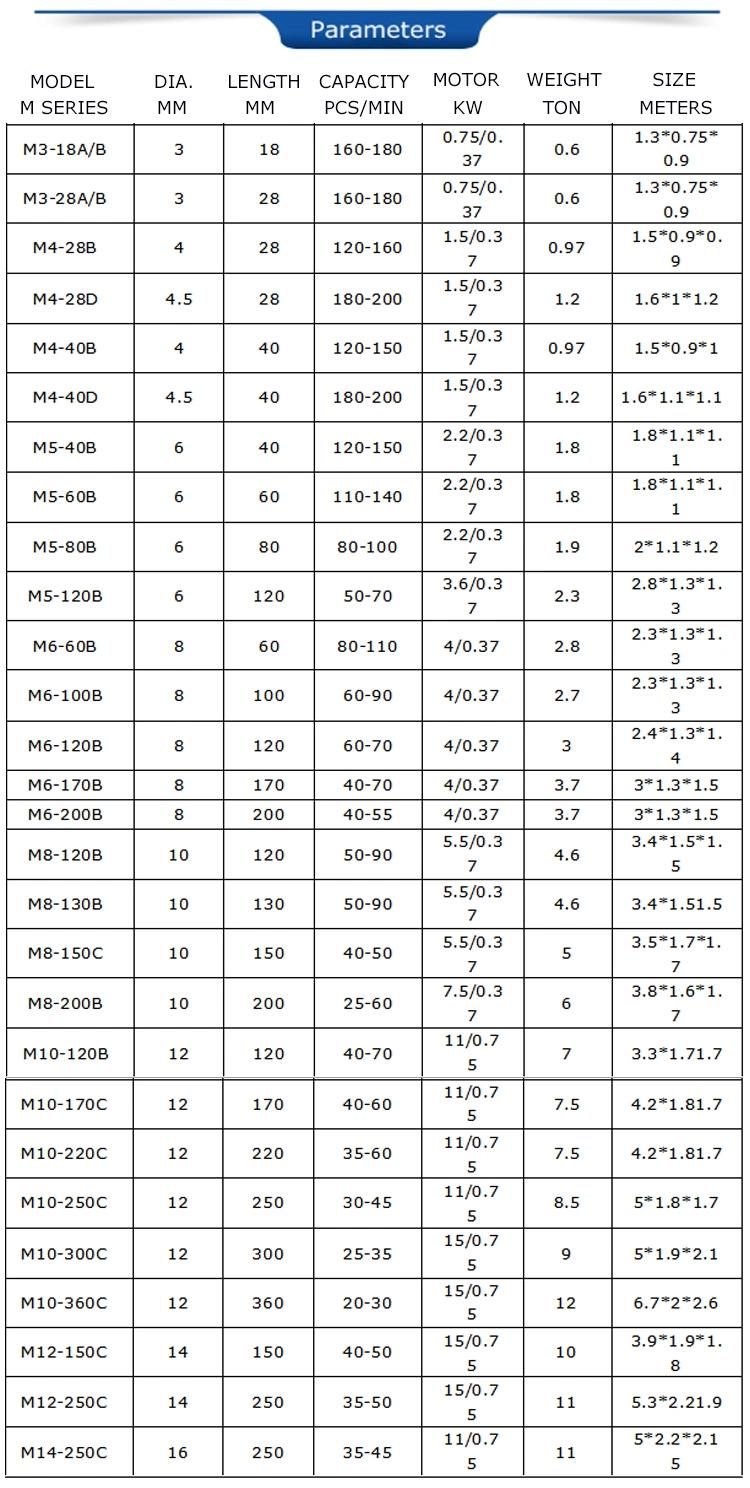

I.Cold heading machine (For Screw Blank)

This equipment adopts cold heading way to make the wire rod upsetting by double-click the whole mould form. Finished Feeding, straightening, cutting material, forming, discharging by one machine.

Main technical parameters:

Detail features of the screw heading machines1.Wire feeding system: High speed lead traction, more accurate and much faster 2.Feeding system: Linkage lever leads to precise feed for the head 3.Straightening system: High precision straightening wheel makes the product more precise 4.Heading system: High precision oil pump for machinery provide more lasting power

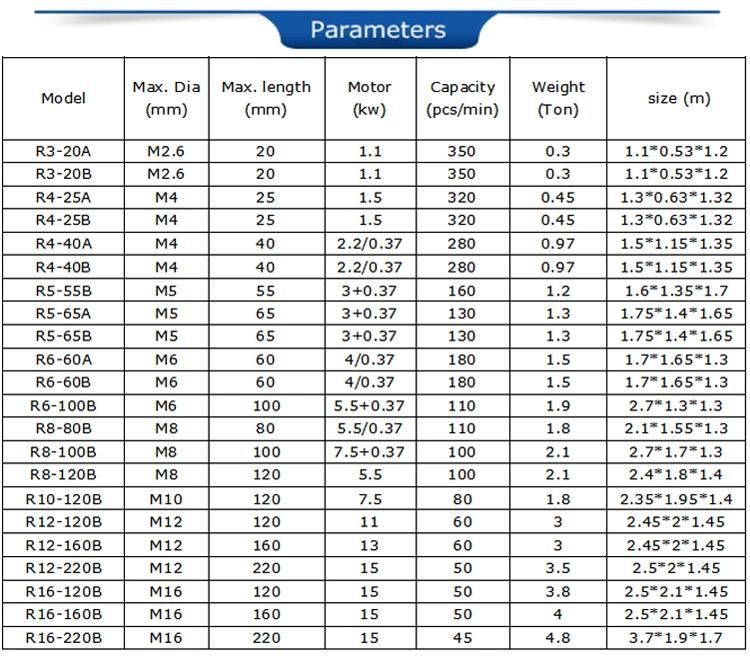

II. Auto Thread Rolling Machine (For Screw Thread)

This equipment adopts two thread profile thread rolling plate staggered 1/2 screw distance design, dead plate is fixed, movable plate equal to dead plate do straight line motion back and forth, when the work piece feed between two plates, movable plate move forward twist work piece, make its surface plastic deformation into thread. Easy to operate, convenient to maintenance, which greatly decrease the technical requirements for workers.

Main technical parameters:

Detail features of the thread rolling machine1.Feeding device : Gear feed, more accurate 2.Raw material processing: High precision mold for the screw blank processing 3.Feeding guide: Transport the screw blanks through the guide rail to the designed location 4.Vibrating disc: The screw blanks can be transfered in orderly queue.

III. End products

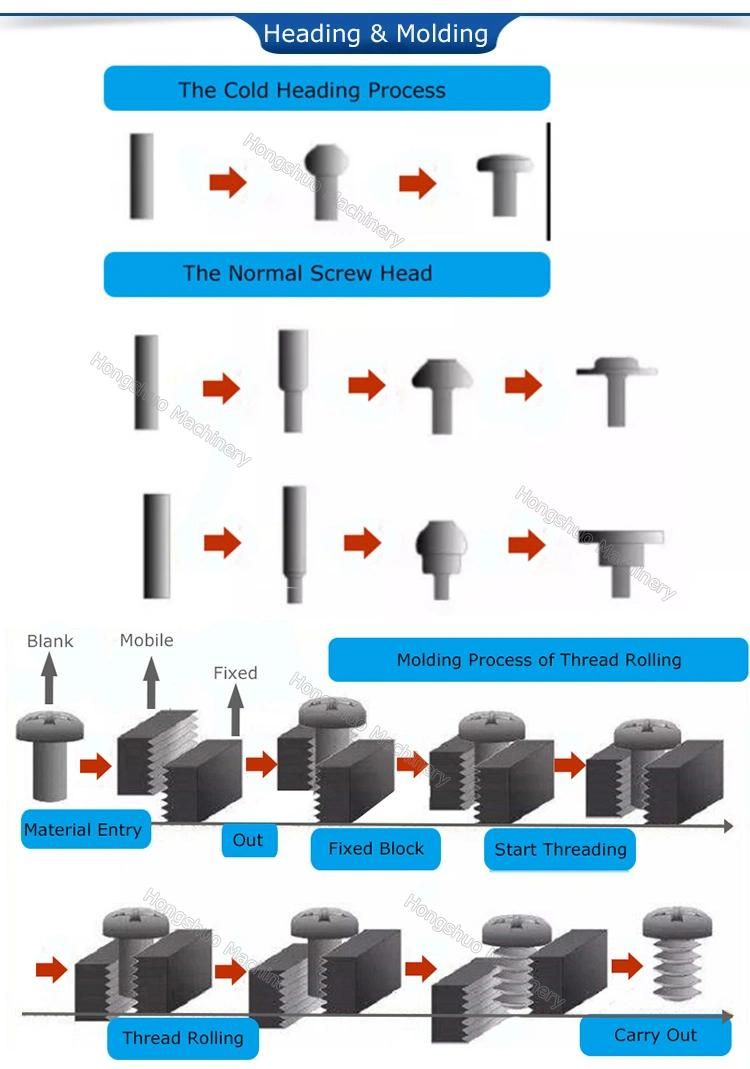

IV. Heading & Molding Process Flow

V. Shipment photos

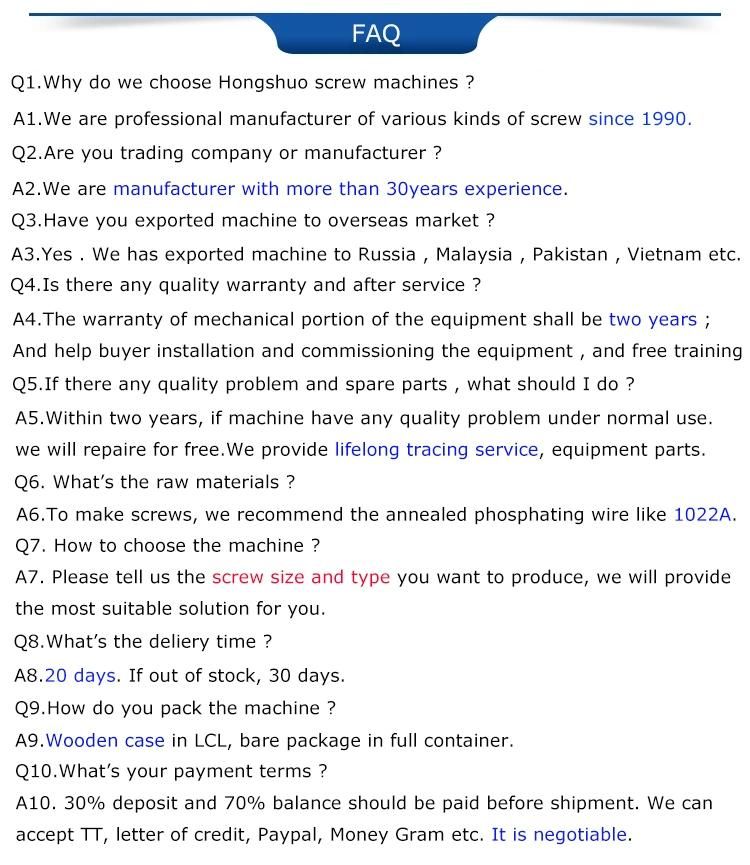

VI. FAQ

VII. Contact Us

VII. Contact Us