350kg Melting Furnace for Steel, Iron, Brass, Copper Alloys

Foshan Hengyang Furnace Manufacturing Co., Ltd.- Control Type:PLC

- Customized:Customized

- Condition:New

- Automatic Grade:Automatic

- Certification:CE, ISO9001

- Type:Special Casting

Base Info

- Model NO.:GW-350kg

- Application:Copper Melting Furnace

- Working Temperature:0-1800 Degrees

- Furnace Capacity:350kw

- Rated Power:250kw

- Input Voltage:380V, 3phase

- Input Current:400A

- Delivery Time:20 Days

- Warranty:1 Years

- Transport Package:International Export Packing Standard

- Specification:1300*1000*1000mm

- Trademark:HENGYANG

- Origin:China

- HS Code:8514200090

- Production Capacity:86sets,Month

Description

Cast copper melting(1350ºC)(t/h) (Kw) KHZ Melting Power consumption Melting Power consumption Rate(t/h) (kw.h/t) Rate(t/h) (kw.h/t) 0.1 100 2.5 0.1 800 0.1 490 0.15 160 2.5 0.15 750 0.15 480 0.35 250 2.5 0.35 700 0.35 460 0.5 350 1 0.5 650 0.5 450 0.75 500 1 0.75 630 0.75 440 1 750 1 1 600 1 430 1.5 1000 1 1.5 580 1.5 430 2 1500 1 2 560 2 430 3 2000 1 3 530 3 430 5 2500 1 5 520 5 430 8 5000 0.5 8 520 8 430 10 5000 0.5 10 520 10 430 15 8000 0.5 15 520 15 430 20 10000 0.5 20 520 20 430 30 15000 0.5 30 520 30 430

Spare part 1:Thyristor

Brand: TECHSEM Group and CSR Group, the above two companies are leading thyristor manufacturing industry in China

Function: Stable, have strong ability to resist strong current, durable, not easy to damage

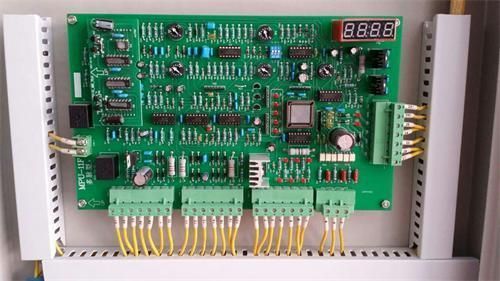

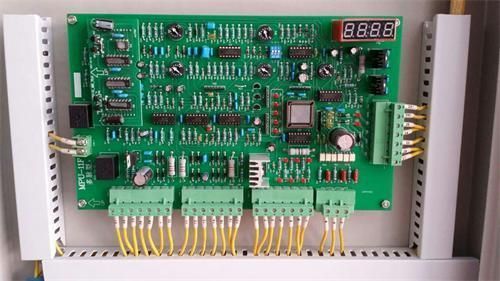

Spare part 2:Control circuit board

Brand: Hengyang Furnace, developed by our own R&D Team

Function: Double tested before production, carefully checking, have a great control on the quality, every customer comment its stablility.

Spare part 3:Induction coils

Induction coil installs in the central of the furnace, it has spiral body with rectangular empty brass circle around, the pipe center should be cooled with water. Copper bar outside induction coil will connect with water-cooling cable. The lining closes to induction coil, which made by burden, the method you can find in related parts below.

Safty Protection:

• Main circuit short circuit protection

• Main circuit phase loss protection

• Main circuit phase fault protection

• SCR over-current protection

• SCR overvoltage protection

• Cooling water temperature protection

• Low water pressure protection

• Furnace leakage protection

• Intermediate frequency power failure protection

• Intermediate frequency electric furnace fault protection rate and increase the life obviously

Why Choose us:

1,Low power consumption

Large current system made of pure copper as conductive medium, the whole circuit with less resistance. Electrode arm shaped as copper-clad box type, resistance and heat can be reduced efficiently. Reasonable arrange of all conductive systems to minimize the resistance of every circuit.

2,Safety & Stability

Full set of hydraulic driving system equipped with accumulator to ensure stability of facilities in the operation process. Whist, equipments can go on the motion when there any emergency accidents happen.

3,High Power Factor

Our power factory could reach over 98%, which could greatly reduce the capacitor box quantities. However we still equip enough capacitor box quantities, which mean your furnace is much much more efficient.

4.High flexibility & Maximum simplicity of operation

HMI used in electrical automation control, interface simulates the real form of furnace, which make the operation more convenient. Mixing feedstock, charging feedstock, melting, tapping all the commands can be implemented by computer.

5.More Durable

We get 6 thyristors on the left, 8 on the right, so even if one thyristor is damaged, our furnace still could be continued use. But many other factories only get only 4 on the right,the whole equipment cannot be used anymore when one thyristor is damaged.

Spare part 1:Thyristor

Brand: TECHSEM Group and CSR Group, the above two companies are leading thyristor manufacturing industry in China

Function: Stable, have strong ability to resist strong current, durable, not easy to damage

Spare part 2:Control circuit board

Brand: Hengyang Furnace, developed by our own R&D Team

Function: Double tested before production, carefully checking, have a great control on the quality, every customer comment its stablility.

Spare part 3:Induction coils

Induction coil installs in the central of the furnace, it has spiral body with rectangular empty brass circle around, the pipe center should be cooled with water. Copper bar outside induction coil will connect with water-cooling cable. The lining closes to induction coil, which made by burden, the method you can find in related parts below.

Safty Protection:

• Main circuit short circuit protection

• Main circuit phase loss protection

• Main circuit phase fault protection

• SCR over-current protection

• SCR overvoltage protection

• Cooling water temperature protection

• Low water pressure protection

• Furnace leakage protection

• Intermediate frequency power failure protection

• Intermediate frequency electric furnace fault protection rate and increase the life obviously

Why Choose us:

1,Low power consumption

Large current system made of pure copper as conductive medium, the whole circuit with less resistance. Electrode arm shaped as copper-clad box type, resistance and heat can be reduced efficiently. Reasonable arrange of all conductive systems to minimize the resistance of every circuit.

2,Safety & Stability

Full set of hydraulic driving system equipped with accumulator to ensure stability of facilities in the operation process. Whist, equipments can go on the motion when there any emergency accidents happen.

3,High Power Factor

Our power factory could reach over 98%, which could greatly reduce the capacitor box quantities. However we still equip enough capacitor box quantities, which mean your furnace is much much more efficient.

4.High flexibility & Maximum simplicity of operation

HMI used in electrical automation control, interface simulates the real form of furnace, which make the operation more convenient. Mixing feedstock, charging feedstock, melting, tapping all the commands can be implemented by computer.

5.More Durable

We get 6 thyristors on the left, 8 on the right, so even if one thyristor is damaged, our furnace still could be continued use. But many other factories only get only 4 on the right,the whole equipment cannot be used anymore when one thyristor is damaged.