Multi-Station Cold Forging Machine

HARBIN RAINBOW TECHNOLOGY CO., LTD.- After-sales Service:Site Service, Online Service

- Automatic Grade:Automatic

- Warranty:1 Year

- Certification:CE

- Product Name:Cold Forging Machine

- Fuction:Part Former

Base Info

- Model NO.:RBP-106S

- Transport Package:Wooden Case

- Specification:RBP-106S

- Trademark:Rainbow

- Origin:China

- HS Code:84629990

- Production Capacity:100

Description

Basic Info.

Model NO. RBP-106S Transport Package Wooden Case Specification RBP-106S Trademark Rainbow Origin China HS Code 84629990 Production Capacity 100Product Description

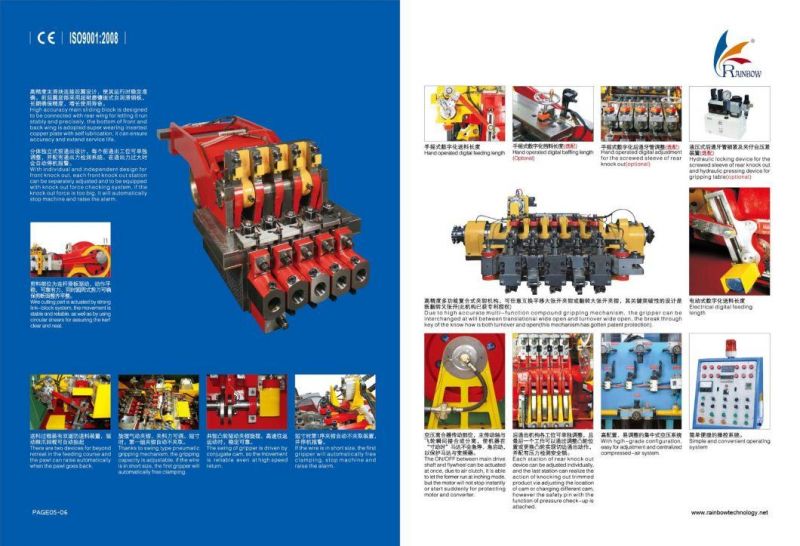

Multi-station cold forging machine is a specialized machine with high precision,high productivity and more automation among metal forging machinery. It is used to produce different kinds of bolts, other metal parts in fastener industry.Salient Features:

1. The air clutch brake system has been designed to actuate with low current and as "inching", "single stroke" and "continuous running". Except "inching", the machine will always stop at the backward position of the main slider while operating in largest space.2. Two sorts of transfers system for customer to choose: swing type (general equipped) and universal type (optional), equipped with pneumatic gripper, it can simplify the demand of operation, and is more stable when the machine runs at high speed.

3. Main motor is equipped with speed-adjust transducer, PLC control system, computer automatic man-machine interface system(Optional), these equipment make lots of convenience for customer to adjust the dimension of the non-standard products.

4. Feeding wheel and claw system are both drived by cylinder, the claw can stretch automatically when it goes back in order to reduce abrasion and noise. Feeding material and stop feeding material are controlled by two claws, the feeding material system is equipped with device for avoiding material draw back.

5. Perfect inspection system: short material inspecting and eliminating, inspection of the low location of oil pressure and air pressure, transfer system floating inspection system, overload, and lightload stop system to protect the lathe and dies and prolong the service life of them.

6. When the customer prepare to adjust the side cutting screw, they only need to adjust side cam's station position, then they can achieve side cutting purpose. When the workpieces need not side cutting, customer can reset it to achieve the change from side cutting to former station.

7. High strengthened-material lathe bed, lengthened main and subsidiary slider structure and "pedrailtype" slider which is adopted domestically for the first time realize "zero space" assembling which assures the precision of the main slider movement and lengthens their service life of dies.

8. The main parts of all type machines have adopted strict casting procedure and annealing