220V CNC Plasma/Flame Portable Cutting Machine

Wuxi Longteng Welding and Cutting Equipment Co., Ltd.- After-sales Service:Online Servie, Field Service

- Warranty:13 Months

- Customized:Customized

- Layout:X Y Z Axis

- Cutting Material:Copper, Carbon Steel, Iron, Aluminum, Metal Alloy, Stainless Steel

- Automatic Grade:Automatic

Base Info

- Model NO.:HNT-1600

- Power Source:Electric

- Cutting Mode:Plasma Cutting

- Color:Can Be Customized

- Cutting Length:Can Be Customized

- Cutting Speed:6000mm,Min

- Cutting Area:1600X3400mm, 1500X3000mm

- Transport Package:Plywood Package

- Specification:1600x3400mm

- Trademark:OEM

- Origin:China

- HS Code:8456401000

- Production Capacity:100 Sets,Month

Description

IV. Numerical Control System Technical Description:

Model: HNP

1) 7'' colorful LCD display;

2) Film-cover operation key;

3) USB port supports program transfer;

4) 32M Memory for users' program;

5) Built-in shape library of commonly used figures;

6) Break-point & power-cut restoration;

7) Return to reference point;

8) Mirror image;

9) Two-axes straight line and arc interpolation;

10) Pause, forward, backward, and speed regulation while machine working.

V. Program software: FastCAM Professional Edition

Main functions:

- Draw the part or import DXF files a

- CAD Clean & File compression for quality cutting a

- Edit, Verify and Output NC code a

- Interactive & Automatic Nesting a

- Automatic Tool Path Programming a

- Common Cutting & Bridging a

- Bulk processing of files for volume & speed

Automatic 'EVERYTHING': Tool pathing, Pierce, Sequencing, Nesting, Cutlist;

Multi-job, Multi-part, Multi-plate mixed & Remant Nesting;

Improved material yield and smart cutting technologies including common cutting and 4 types of bridging (for various industries)..

Dramatic reduction in pierce.

A 50% reduction in programming time with automatic tool pathing.

Bulk features for programming speed-file import, editing, export, etc.

VI. Package Dimensions and Weights

Every Microbee Plus will be packed into 2 or 3 plywood cases.

| Content | Wooden cases | Dimension | Net Weight | Gross Weight |

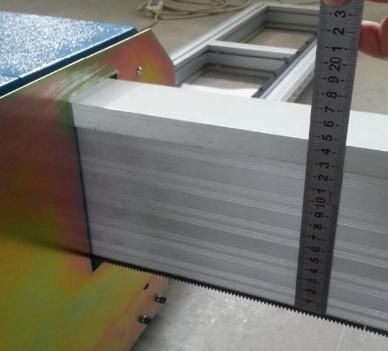

| Central unit of CNC cutting machine | 1 case | 740X520X480 (mm) | 50KG | 60KG |

| Longitudinal rails, cross beam, oxy-fuel torch, cables and other accessories | 1 case | 4120X470X240 (mm) | 110KG | 165KG |

| Plasma Power Source and Machine torch (Option) | 1 case |