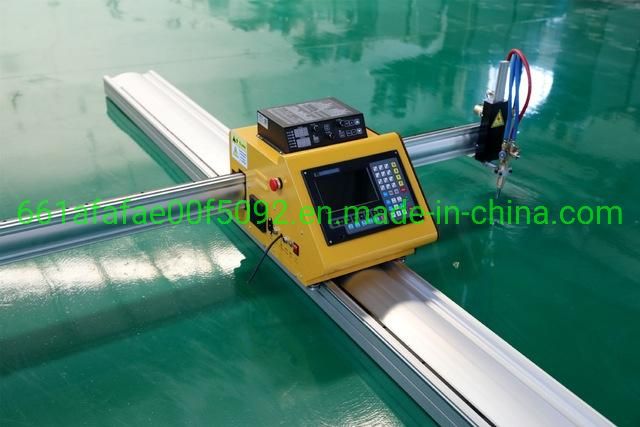

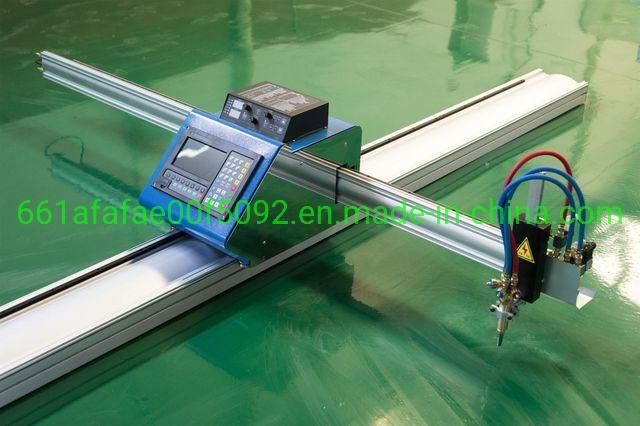

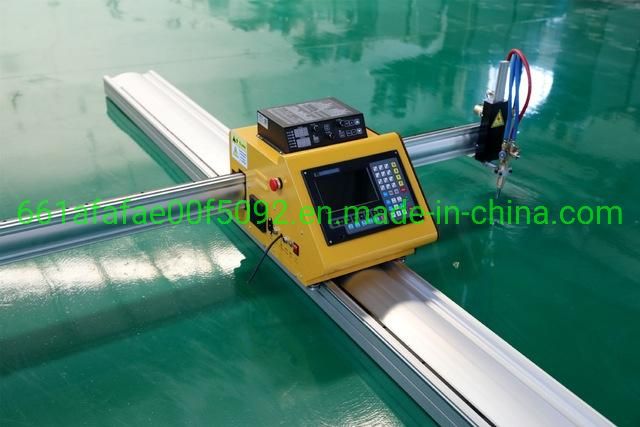

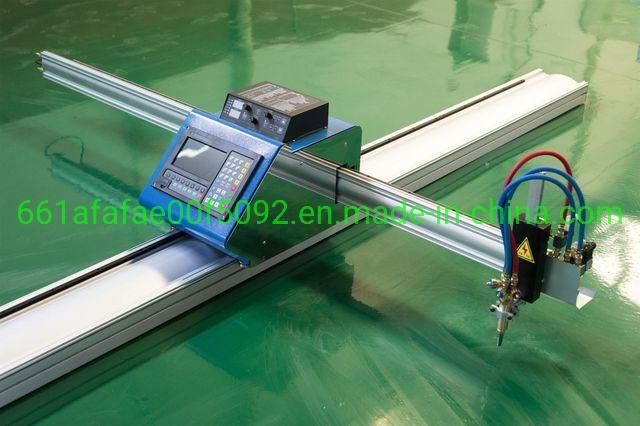

1530 Portable CNC Plasma Flame Cutting Machine for Metal Sheet

Wuxi Lemar Machinery Equipments Co., Ltd.- After-sales Service:Online Video Instruction

- Warranty:13 Months

- Customized:Customized

- Layout:Horizontal

- Cutting Material:Copper, Carbon Steel, Iron, Aluminum, Metal Alloy, Stainless Steel

- Automatic Grade:Automatic

Base Info

- Model NO.:CNC-1530

- Power Source:Electric

- Cutting Mode:Plasma Cutting

- Model:CNC-1530

- Cutting Gas:Oxyacetylene Oxygen,Oxyfuel Propane Acetylene

- Plasma Cutter:Dual Drive Portable Plasma Cutter

- Optional Plasma:Hypertherm Power,China Plasma

- Nest Software:Fastcam Startcam

- Power:220V ,380V

- Plasma Model:Lgk 63A 80A 100A 120A 200A 300A 400A

- Control System:F2100b

- Effective Cutting:1500*3000 mm

- Deliver:3-7days

- Other Model:1630 1525 1215 2060 3060 2430

- Application:Industrial Metal Plasma Cut

- Weight:100 , 200 Kg

- Motor Type:Step Motor

- Torch Height Control:Optional

- Transport Package:Standard Package

- Specification:Flame Acetylene Gas or Liquefied CNC cutter

- Trademark:Lemar

- Origin:Wuxi, China

- HS Code:8456909000

- Production Capacity:1000 PCS,Year

Description

Relative humidity: 90%

Features of CNC Plasma Flame cutting machine portable type:

1.Portable CNC plasma flame cutting machine is an integral mobile type, which is used like a "little sports car".

2.It can be directly placed on the steel plate to be unloaded, which is convenient and flexible to use

3.Portable mini CNC Plasma cutting machine is Suitable for precision cutting and blanking of carbon steel, stainless steel and non-ferrous metal sheets of various thicknesses

4.Plasma miniature automatic height adjustment system can be configured.

5.Equipped with a U disk interface, the office design graphics are transferred to the cutting machine through the U disk. Simple graphics can be directly input to the cutting machine on site;

Commonly used plasma power supply guide:

Domestic LGK100A: perforation cutting thickness 2-10mm;

Domestic LGK120A: perforation cutting thickness 2-15mm;

Domestic LGK200A perforation cutting thickness 2-25mm;

Hypertherm Pmax105: Perforation cutting thickness 2-18mm.

Why choose Lemar?

1. Has a professional R&D, production, sales and service team

2. Complete CNC cutting products: gantry type CNC Plasma flame big cutting machine, desktop CNC Plasma & Flame gas cutting machine, portable mini CNC Flame plasma oxygen cutting machine, pipe cutting, etc.;

3. Provide free track installation basic drawings, cutting table drawings and external hoisting pipe gas path and scribing drawings;

4. Free installation, commissioning and training services;

5. Provide process guidance services free of charge;

6. Free one-year warranty and lifetime technical support services.

Features of CNC Plasma Flame cutting machine portable type:

1.Portable CNC plasma flame cutting machine is an integral mobile type, which is used like a "little sports car".

2.It can be directly placed on the steel plate to be unloaded, which is convenient and flexible to use

3.Portable mini CNC Plasma cutting machine is Suitable for precision cutting and blanking of carbon steel, stainless steel and non-ferrous metal sheets of various thicknesses

4.Plasma miniature automatic height adjustment system can be configured.

5.Equipped with a U disk interface, the office design graphics are transferred to the cutting machine through the U disk. Simple graphics can be directly input to the cutting machine on site;

Commonly used plasma power supply guide:

Domestic LGK100A: perforation cutting thickness 2-10mm;

Domestic LGK120A: perforation cutting thickness 2-15mm;

Domestic LGK200A perforation cutting thickness 2-25mm;

Hypertherm Pmax105: Perforation cutting thickness 2-18mm.

Why choose Lemar?

1. Has a professional R&D, production, sales and service team

2. Complete CNC cutting products: gantry type CNC Plasma flame big cutting machine, desktop CNC Plasma & Flame gas cutting machine, portable mini CNC Flame plasma oxygen cutting machine, pipe cutting, etc.;

3. Provide free track installation basic drawings, cutting table drawings and external hoisting pipe gas path and scribing drawings;

4. Free installation, commissioning and training services;

5. Provide process guidance services free of charge;

6. Free one-year warranty and lifetime technical support services.