High Speed Track Cutting Roofing Roll Forming Machine

Zhangjiagang City Saibo Science & Technology Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

- Feature:High Efficiency

- Certification:ISO9001, CE

- Warranty:12 Months

Base Info

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Color:Blue and Yellow

- Speed:30m,Min

- Transport Package:Suitable for Sea Packing

- Specification:CE, SGS

- Trademark:SAIBO

- Origin:Jiangsu, China

- HS Code:84552210

- Production Capacity:300sets,Year

Description

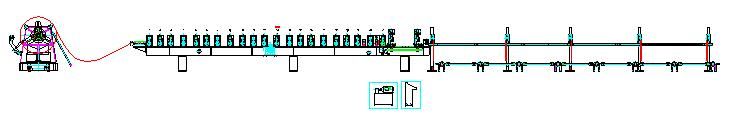

2. The Chart of Process Flow

10T Hydraulic Uncoiler-Roll Forming-Track cutting-Auto stacker

3. Specification of Components

- Width of feeding: 1250mm

- Capability: 10 Ton

- Inter diameter: 470-520mm

- Maximal out diameter: 1500mm

- Working speed: 0--35m/min adjustable

- Main motor power: 7.5KW AC motor

- Hydraulic power: 5.5kw

- Coil weight (Max): 10 Ton

- Working lift journey: Maximal 250mm

- Working function: forward and reverse movable

- Move journey: maximal 3 meters

- Roller material:ASTM1045 chrome plated surface with chrome

- Shaft diameter: ¢76mm material: SAE1045 with quenching and tempering

- Motor power: 15kw

- Structure: Cast iron structure

- Roll station: About 20stations

- Productivity: 30m/min

- Drive system: by gear box

- Cutting after forming: Cut the sheet after roll forming to required length

- Cutting motion: The main machine won't stop when cutting, continuous tracking cutting.

- Adopt servo motor and ball screw to make the speed and size more stable.

- Servo power: 2.9kw

- Material of blade: CR12with heat treatment

- Length measuring: Automatic encoder length measuring

- Tolerance of length: 3m+/- 1.5mm

4. Warranty

- Warranty: 1 year warranty from date of shipment

- Guarantee:

2: Repairs will not be performed free of change even during the guarantee period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after installation

3:Air ticket, transportation cost, hotel, meals and 80$ per day shall be for purchaser's account if manufacturer's engineer has to be send to purchaser's factory to maintain the machine during the guarantee period.