Simple Resin Sand Recycling Equipment

Qingdao Ding Li Machinery Co., Ltd.- After-sales Service:After-Sales Service

- Warranty:One Year Warranty,

- Control Type:PLC

- Customized:Customized

- Condition:New

- Automatic Grade:Automatic

Base Info

- Model NO.:10t,h

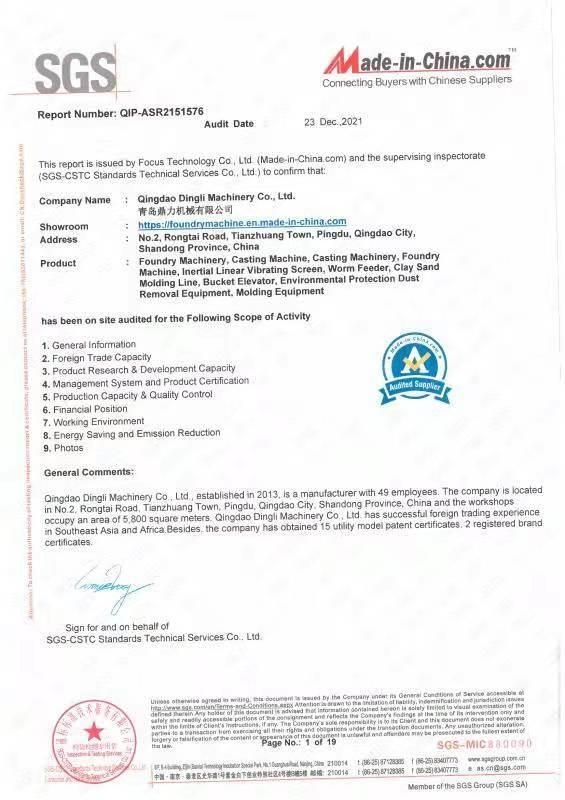

- Certification:CE, RoHS, GS, ISO9001

- Type:Sand Casting

- Transport Package:Custom Made

- Trademark:DL

- Origin:Qingdao, China

- HS Code:8474802000

- Production Capacity:800

Description

Basic Info.

Model NO. 10t/h Certification CE, RoHS, GS, ISO9001 Type Sand Casting Transport Package Custom Made Trademark DL Origin Qingdao, China HS Code 8474802000 Production Capacity 800Product Description

Resin sand equipment, resin sand production line series products are mainly composed of sand block crusher, magnetic separator, regenerator, wind separation device, resin sand mixer and so on.(1) Vibration crushing and regenerating machine: the old sand falling from the vibrating shakeout machine must be crushed first, and the sand blocks of different sizes are broken into sand particles, and then the iron and sundries in the sand are removed by magnetic separation and sieving. The multi-functional vibration regenerator produced by our factory uses two cross-symmetrical vibration motors installed at the bottom to make the sand blocks collide with each other, and the sand blocks are broken during the vibration and conveying process. Resin film and burnt carbonized material regenerate old sand. This regeneration device has both crushing and regeneration functions, but generally the removal rate is lower than that of the centrifugal impact type. The process of regeneration only by vibratory crusher is sometimes called "soft regeneration".

(2) Centrifugal impact regenerator: also known as centrifugal rotor regenerator, the old sand falls from the upper conduit, and the sand is thrown to the impact ring by the high-speed rotation of the sand throwing disc. In the impact ring, the sand is refracted three times, The sand particles rub against each other and collide with each other, so that the small sand mass is broken, and the inert film on the surface of the sand particles is broken to achieve the purpose of stripping. When the removal rate of one cycle does not meet the requirements, the old sand can be returned for processing or two or three identical units can be used in series.

(3) The micropowder separation equipment is also called the wind separator, also known as the flow curtain type micropowder separator. The working principle: the sand flows down from the sand hopper and the baffle, and blows from the horizontal direction of the air inlet to remove the fine powder with small particles and low density. And the dust is taken away through the air outlet and enters the settling chamber, and the normal sand directly falls on the vertical baffle for the second sorting. The sand flow can be controlled by adjusting the baffle, and the dust removal effect can be controlled by adjusting the air volume and air speed.

(4) The correct selection of sand mixing equipment has a great influence on the performance of resin sand. The requirements for the sand mixer are quantitative and accurate (for example, the flow error of resin and curing agent should not exceed 3%, and the sand flow error should not exceed 5%), and the mixing and grinding should be uniform (the uniformity of sand mixing should not exceed 10%, and try to reduce it as much as possible. The head sand and tail sand are not uniform), the film coating effect is good, and the medium (core) sand has less heat in the sand mixing process. In addition, factors such as equipment, manufacturing quality, reliability of use, ease of maintenance, and product price should also be considered.

The resin sand mixers produced by our company are divided into two types: single-arm and double-arm, both of which are continuous sand mixers.

Its characteristics are as follows:

The binder supply system adopts electric variable diaphragm pump (imported from Italy) and gear pump, which are light in weight, compact in size, stable and reliable in flow.

The sand is mixed evenly, which effectively ensures the quality of the molding (core making).

The sand mixing time is short, there is no head and tailing sand, and the discharge is clean after the machine is stopped.

The fully open sand mixing and stirring arm is convenient for blade cleaning or adjustment, and is convenient for operation and maintenance.

The inlet of the sand mixer can be equipped with a new and old sand ratio regulator according to production needs, which can accurately control the sand production and the ratio of the old sand.

The electrical appliances are controlled by PLC, with sufficient restriction and protection, analog display, stable work, and automatic production.

| productivity(t/h) | 8-10 |

Qingdao Dingli Machinery Co., Ltd. is located in the beautiful seaside - Pingdu, Qingdao. The company integrates scientific research, manufacturing, installation and commissioning, and after-sales service. Mainly produces resin sand production line, clay sand production line, coated sand production line equipment, various sand processing stand-alone equipment, etc. The company has advanced casting machinery manufacturing and development technology, and the products produced can fully meet the needs of international and domestic markets. The company has an excellent design and development team, a skilled construction team, a domestic leading casting equipment design concept, and a perfect after-sales service system. It is willing to sincerely cooperate with the majority of casting enterprises to create a better tomorrow.

Qingdao Dingli Machinery Co., Ltd. is located in the beautiful seaside - Pingdu, Qingdao. The company integrates scientific research, manufacturing, installation and commissioning, and after-sales service. Mainly produces resin sand production line, clay sand production line, coated sand production line equipment, various sand processing stand-alone equipment, etc. The company has advanced casting machinery manufacturing and development technology, and the products produced can fully meet the needs of international and domestic markets. The company has an excellent design and development team, a skilled construction team, a domestic leading casting equipment design concept, and a perfect after-sales service system. It is willing to sincerely cooperate with the majority of casting enterprises to create a better tomorrow.In line with the business philosophy of "down-to-earth, integrity-based, service-oriented, continuous innovation", through continuous efforts. We have developed a series of complete processing equipment with our own efforts and focus to meet the different needs of the majority of users.