Dx 1100 Cold Bending Metal Sheet Roof Tile Forming Machine in China

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

- Feature:High Efficiency

- Certification:CCC, ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:DX 1100-220-28

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Name:Metal Sheet Roof Tile Forming Machine

- Processing Material:Aluzinc,Galvanized Steel,Colored Steel Coil

- Material Thickness:0.3-0.8mm

- Effective Width:1100mm

- Feeding Width:1250mm

- Motor Power:4kw

- Shaft Diameter:80mm

- Forming Steps:15 Steps

- Roller Material:45# Forged Steel, with Hard Chrome Plating

- Main Frame:350h Steel

- Transport Package:Water-Proof Packaging, Covered with Plastic Film

- Specification:DX1100-220-28

- Trademark:DIXIN

- Origin:Botou Hebei China

- HS Code:845522

- Production Capacity:20 Set Per Year

Description

Basic Info.

Model NO. DX 1100-220-28 Customized Customized Advantage Use Widely Condition New Name Metal Sheet Roof Tile Forming Machine Processing Material Aluzinc/Galvanized Steel/Colored Steel Coil Material Thickness 0.3-0.8mm Effective Width 1100mm Feeding Width 1250mm Motor Power 4kw Shaft Diameter 80mm Forming Steps 15 Steps Roller Material 45# Forged Steel, with Hard Chrome Plating Main Frame 350h Steel Transport Package Water-Proof Packaging, Covered with Plastic Film Specification DX1100-220-28 Trademark DIXIN Origin Botou Hebei China HS Code 845522 Production Capacity 20 Set Per YearProduct Description

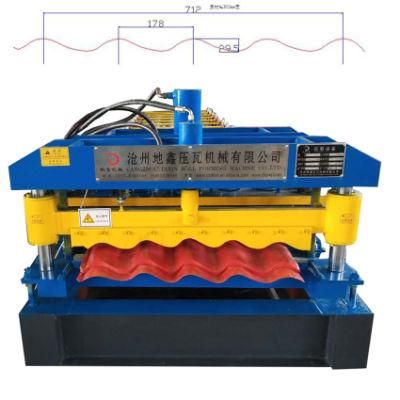

DX 1100 Cold Bending Metal Sheet Roof Tile Forming Machine in ChinaDX1100-220-28 Glazed Tile Roll Forming Machine

Technical parameters:

1. Material spec: Colored steel sheet, galvanized steel sheet, aluminium sheet

2. Thickness of coil sheet: 0.3-0.8mm

3. Roller material: High grade NO. 45 forged steel, with hard chrome plating on the surface of roller with thickness 0.05mm

4. Shaft material: High grade NO. 45 carbon wrought steel

5. Cutting blade: Cr12 mould steel with quenched treatment

6. Diameter of shaft: 70-90mm

7. Thickness of medium plate: 14mm

8. Main frame: 300H/U steel

9. Number of forming steps: 15rows

10. Productivity: 6-10m/min

11. Main motor power: 4kw

12. Hydraulic station power: 4kw

13. Hydraulic pressure: 10-12MPa

14. Controlling system: PLC computer control

15. Voltage: 380V 3Phase 50Hz or at buyer's requirement

The packing

Standard packing

Waterproof packageI

Iron wire will be needed to fix machines with containers.

Maintenance: Quite easy.

1 Equipment should always be wiped, keep clean, and not with muddy water.

2 Regularly feed lubricant to the machine gear, chain and moving parts to reduce friction and avoid rusting.

Service

1 One year warranty after delivery and lifelong technical support

2 If some parts of machines go wrong during this period,

DIXIN can offer our best,

But you should pay for seafreight or other fee.

3 on-site training available. Most of the time is not necessary.

The training period would be for no more than one week with the customer paying for the visa,

Return ticket, food, accommodations and a daily wage of USD 80

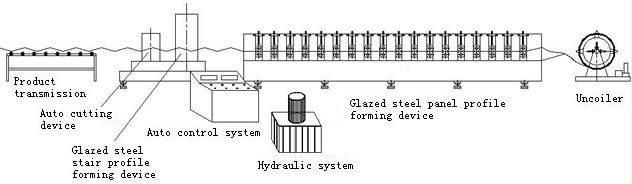

| 1 uncoiler and its base |

| 2 coil sheet guiding equipment |

| 3 roll forming system |

| 4 hydraulic pressing equipment |

| 5 post cutting equipment |

| 6 hydraulic station |

| 7 controlling system |

| 8 supporter table |

Contact: Bella Hao : +8618231723279