Powder Metallurgy Sintered Metal Parts

Ningbo Twirl Motor Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM

- Customized:Customized

- Material:Sintered Metallurgy

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts

Base Info

- Transport Package:Caryon+ Ploy Bag

- Specification:Fn-0205

- Trademark:customized

- Origin:Zhejiang, China

Description

Basic Info.

Transport Package Caryon+ Ploy Bag Specification Fn-0205 Trademark customized Origin Zhejiang, ChinaProduct Description

The Advantage of Powder Metallurgy Process1.Cost effective: The final products can be compacted with powder metallurgy method, and no need or can shorten the processing of machine. It can save material greatly and reduce the production cost.

2.Complex shapes: Powder metallurgy allows to obtaining complex shapes directly from the compacting tooling, without any machining operation, like teeth, splines, profiles, frontal geometries, etc.

3.High precision: Achievable tolerances in the perpendicular direction of compacting are typically IT 8-9 as sintered; improvable up to IT 5-7 after sizing. Additional machining operations can improve the precision.

4.Self-lubrication: The interconnected porosity of the material can be filled with oils, obtaining, and then a self-lubricating bearing; the oil provides constant lubrication between bearing and shaft, and the system does not need any additional external lubricant.

5.Green technology: The manufacturing process of sintered components is certified as ecological, because the material waste is very low, the product is recyclable, and the energy efficiency is good because the material is not molten.

| Product Name | Powder Metallurgy Sintered Metal Parts |

| Material | Powder metal - FN-0205 |

| Technology | Powder Metallurgy - Machining |

| Standard | ISO9001 |

| Surface Treatment | High Frequency quenching, Oil impregnation |

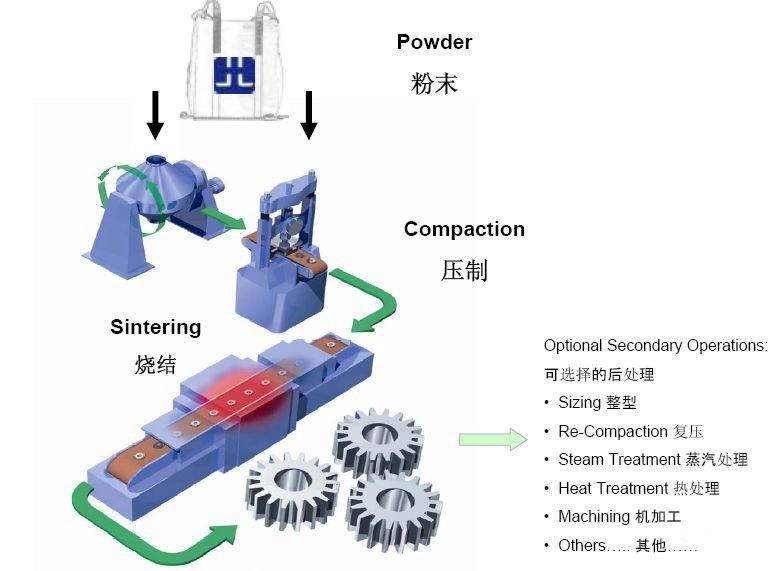

| Process Flow | Powder mixing - Forming - Sintering - Oil impregnation - Sizing -Ultrasonic Cleaning - Steam Oxidation - Oil impregnation - Final inspection - Packing |

| Apperance | No Crumbling, Cracks, Exfoliation, Voids, Metal Pitting and Other Defects |

| Application | building industry machinery |

DETAIL:

Workshop:

Packing:

ship:

FAQ:

Q: Do you make customized products based on our design drawings?

A: Yes, we are a professional metal fabrication supplier with experienced engineering team to make custom products according to clients' drawings.

Q: Will my drawing be safe after you get it?

A: Yes, we won't release your design to any third parties unless have your permission. And we can sign the NDA before you send the drawing.

Q: What is the MOQ?

A: We don't set MOQ, but the price will be better for the larger quantity . Besides, we are happy to make prototype or sample for clients to ensure quality standard.

Q: Whether some samples can be provided?

A: Yes, just need some sample cost, we will return it back when proceed into mass production.

Q: How to deal with the parts received when they are found to be in poor quality?

A: Please rest assured that all our products are QC inspected and accepted with inspection report before delivery and generally there will no non-conformance: in case of non- conformance, please contact us immediately, take some pictures, we will check on the problems and have them reworked or repaired at the first time , the resulting transportation costs will be our side.