Custom High Precision Car Parts Aluminum CNC Machining Parts

Dongguan Qida Hardware Machinery Co., Ltd.- Condition:New

- Certification:ISO9001, Gsg

- Standard:DIN

- Customized:Customized

- Material:Metal

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Base Info

- Model NO.:QD-M-43

- Surface Treatment:Oxidation

- Transport Package:Crate

- Specification:100X80X20mm

- Trademark:QD

- Origin:China

- Production Capacity:1000000,Year

Description

Basic Info.

Model NO. QD-M-43 Surface Treatment Oxidation Transport Package Crate Specification 100X80X20mm Trademark QD Origin China Production Capacity 1000000/YearProduct Description

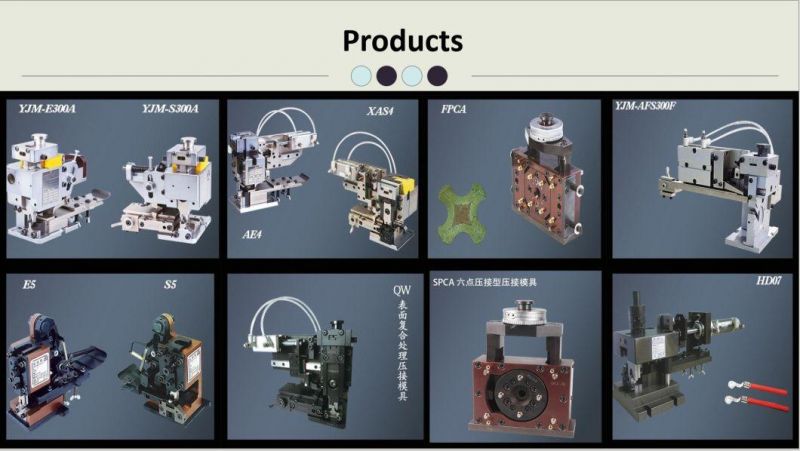

Dongguan Qida Hardware Machinery Co., Ltd. mainly provides intelligent manufacturing solutions for precision metal parts for domestic and foreign customers. The company was established in 2008 and currently has more than 60 units. Various types of high-precision precision equipment manufacturing systems have more than 80 employees. Among them, there are more than 40 senior technical personnel, and signed a talent orientation transfer plan with a number of technical training centers. The company's business involves the precision parts and hardware processing of auto parts, 3C automation equipment, aerospace, engineering machinery, medical, food, new energy battery equipment, instruments and meters, precision instruments, hardware tools and other industries. At the same time, we also provide customers with precision fixture, fixture, mold parts design and manufacturing, special material parts processing (such as ceramics, hard alloy) and automation equipment design, installation, commissioning, and production equipment maintenance, improvement and other related business.

The company's business involves the precision parts and hardware processing of auto parts, 3C automation equipment, aerospace, engineering machinery, medical, food, new energy battery equipment, instruments and meters, precision instruments, hardware tools and other industries. At the same time, we also provide customers with precision fixture, fixture, mold parts design and manufacturing, special material parts processing (such as ceramics, hard alloy) and automation equipment design, installation, commissioning, and production equipment maintenance, improvement and other related business.

In terms of production, we comply with ISO9001: 2015 quality management system, each link of production strictly control, to ensure product performance and quality, at the same time the company also set up the system perfect, the internationalization of scientific and effective information security management system, from the professional and authority level for the customer to provide information security, let the customer's product won't appear the leaks of security risks, make guaranteed delivery cycle.

In terms of production, we comply with ISO9001: 2015 quality management system, each link of production strictly control, to ensure product performance and quality, at the same time the company also set up the system perfect, the internationalization of scientific and effective information security management system, from the professional and authority level for the customer to provide information security, let the customer's product won't appear the leaks of security risks, make guaranteed delivery cycle.  Companies adhering to the "heavy quality, honest, responsible" corporate purposes, with "customer first, in the victory in technology, efficiency and win in the service" business philosophy, in the "fine management, skilled, profound culture, team capable" of the "four" management policy guidance, the company has been in the precision parts processing industry has reached the industry leading level.

Companies adhering to the "heavy quality, honest, responsible" corporate purposes, with "customer first, in the victory in technology, efficiency and win in the service" business philosophy, in the "fine management, skilled, profound culture, team capable" of the "four" management policy guidance, the company has been in the precision parts processing industry has reached the industry leading level.

At present, the company has served nearly 100 customers, 80% of the customers are well-known enterprises in the industry, at the same time, we have a perfect after-sales service system in the industry, continue to use a solid technical basis and strict scientific management system, continuous improvement, beyond customer satisfaction, so that customers feel comfortable before cooperation, after cooperation.

At present, the company has served nearly 100 customers, 80% of the customers are well-known enterprises in the industry, at the same time, we have a perfect after-sales service system in the industry, continue to use a solid technical basis and strict scientific management system, continuous improvement, beyond customer satisfaction, so that customers feel comfortable before cooperation, after cooperation.

Quality Control

Quality Control1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Why Choose Us

1) Design assistance and full engineering support .

2) Professional at OEM CNC parts .

3) Complete production lines for custom turning, milling, CNC machining sheet metal fabrication, stamping, bending, argon welding

and surface treatment.

4) Advanced machine tools, CAD/CAM programming software.

5) Prototype machining capabilities.

6) Strict quality control standards with a highly qualified inspection department .

7) Continually upgrading and advancing our equipment to remain competitive .

8) Small quality is also available.

FAQ

Q: What do I need for offering a quote ?

A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.),quantity, application or samples.

Q: What is your MOQ?

A: MOQ depends on our client's needs, besides,we welcome trial order before mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical requirements and quantity. We always try to meet customers'

requirement by adjusting our workshop schedule.

Q: What kind of payment terms do you accept?

A.: T/T, L/C, Escrow, paypal, western union, moneygram etc.

Q: Is it possible to know how is myproduct going on without visiting your company?

A: We will offer a detailed products schedule and send weekly reports with digital pictures and videos which show the machining progress.