Carbide Tire Stud Pins

Zhuzhou Better Tungsten Carbide Co., Ltd.- Condition:New

- Certification:ISO9001

- Standard:ASTM

- Customized:Customized

- Material:Alloy

- Application:Metal Cutting Machine, Metal Processing Machinery Parts

Base Info

- Model NO.:various

- Grade 1:K10

- Grade 2:P30

- Grade 3:K20

- Transport Package:in Cartons

- Specification:stud pins

- Trademark:ubt

- Origin:China Hunan

- HS Code:820900

- Production Capacity:65 Tons a Month

Description

Basic Info.

Model NO. various Grade 1 K10 Grade 2 P30 Grade 3 K20 Transport Package in Cartons Specification stud pins Trademark ubt Origin China Hunan HS Code 820900 Production Capacity 65 Tons a MonthProduct Description

We provide many different dimensions ( types ) of cemented carbide tire stud pinsTire Studs,Anstislip Tyre Studs,Snow TireSpecial Studs;Professional Produce Carbide Tire Studs.Tire Studs,Anstislip Tyre Studs,Snow Tire Studs, For global provide all kinds of carbideTire Studs, Like Tire Stues, Anstislip Tyre Studs, Anto Tyre Studs, Snow Tire Studs and so on.High quality!

Studs pin Content:WC, Co

Density (g/cm3):10.0-14.0

HAR:>1380 HV30

TRS (N/MM2):1660

Porosity (ISO):Free carbon and graphite phase:Metallurgical:A02B00C00E00

Wear indicators:71±7.5

Specifications:

1.Flat tire studs

2.Screw/sprial tire studs

3.Truck wheel studs

Advantages

--100% pure raw material

--easily installed&removed

-- recycling use

-- sizes & types are available

Professional manufacture for snow studs, tyre studded scews, antiskid boots nails:

New type snow screw car tire studded pin, easy to install and remove without assembling tools.Using in different season, after winter weather can take them off for next turning.Choosing the screw studs only to based on depth of your tire thread.

These stud pins are used for tyre stud because of its high resistance.

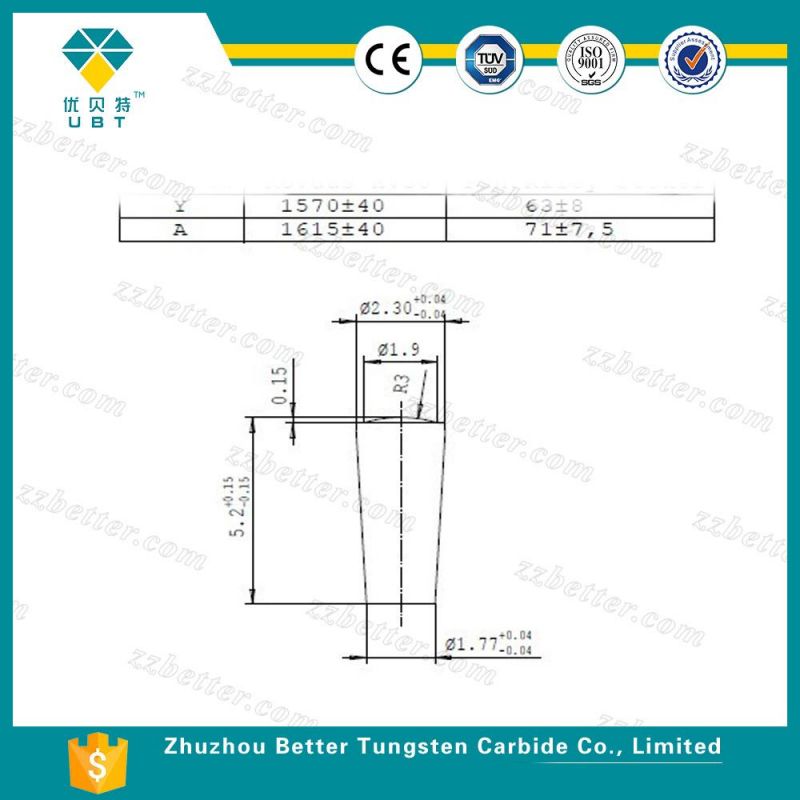

Here's some of our tyre stud pins drawings

Our packing of stud tyre pins :

First in PP bags, then into iron drums, each 25 to 50 kg.