Track Cutting Metal Deck Roll Forming Machine

Zhangjiagang City Saibo Science & Technology Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

- Feature:High Efficiency

- Certification:ISO9001, CE

- Warranty:12 Months

Base Info

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Roll Forming Speed:Not Less Than 25m,Min

- Name:Track Cutting Metal Deck Roll Forming Machine

- Transport Package:Suitable for Sea Packing

- Specification:CE, SGS

- Trademark:SAIBO

- Origin:Jiangsu, China

- HS Code:84552210

- Production Capacity:300sets,Year

Description

Basic Info.

Customized Customized Advantage Use Widely Condition New Roll Forming Speed Not Less Than 25m/Min Name Track Cutting Metal Deck Roll Forming Machine Transport Package Suitable for Sea Packing Specification CE, SGS Trademark SAIBO Origin Jiangsu, China HS Code 84552210 Production Capacity 300sets/YearProduct Description

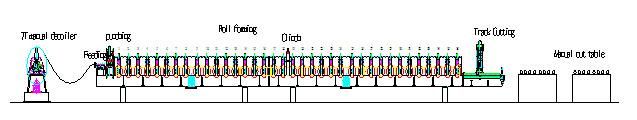

1: 7T Manual decoilerDimensions: 1700mm*1000mm*800mm

Width of feeding: 1000mm

Capability: 7Ton

Inter diameter: 480-570mm

Maximal out diameter: 1500mm

Mode of expand &fight: inner expand &fight by manual

Way of feeding: manual

Color: blue

2: Feeding→punching→roll forming(clinch) →Heavy vertical track cutting

Feeding

Adjustable center of the forming rollers and of sufficient length to prevent lateral movement of the strip on its entry to flattener.

Feeding type: adjustable

Feeding width range:base on profile

Entrance and guide roller: diameter is ¢70mm, material is SAE1045, surface with chrome

Punching

Punching is after feeding and before roll forming

Machine adopt hydraulic punching

Adopt same hydraulic with the post punching

Forming Section (clinch)

Material of the profile: PPGI/PPGL/GI(FULL HARD)

Thickness range: 0.5-0.8mm

Main motor power:15kwx2, AC motor, motor inside of main machine(according the final design)

Machine Voltage, Frequency, Phase: 220 V, 60 Hz, 3Phase

Roll station:36 stations include clinch (according the final design)

Embossing: design base on customer request

Roller material:ASTM1045 chrome plated surface with hardnesss,CNC,

Shaft diameter: ¢85mm material: SAE1045 with quenching and tempering

Machine roll forming speed:not less than 25m/min

Transmission: by chain, one inch, double line

Roll former has leveling bolts in the base for adjust the leveling

Machine base frame adopt H beam welding steel

Machine adopt metal wall as station

To avoid accidents, all of drive part adopt protect cover

Color of machine: Blue and yellow (or base on customer request)

Post track cutting system

Cutting after forming: Cut the sheet after roll forming to required length

Machine track cutting, when cutting, the main roll forming part is non-stop (in no punching condition)

Material of blade:HSS(high speed steel)

Length measuring: Automatic encoder length measuring, brand: Omron

The cutting sequence is also contained and controlled by the same PLC program

Tolerance of length: +/- 1.5mm for each piece end product