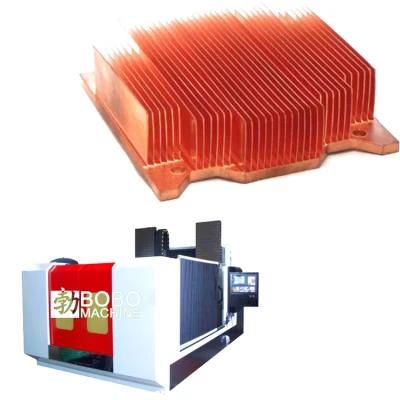

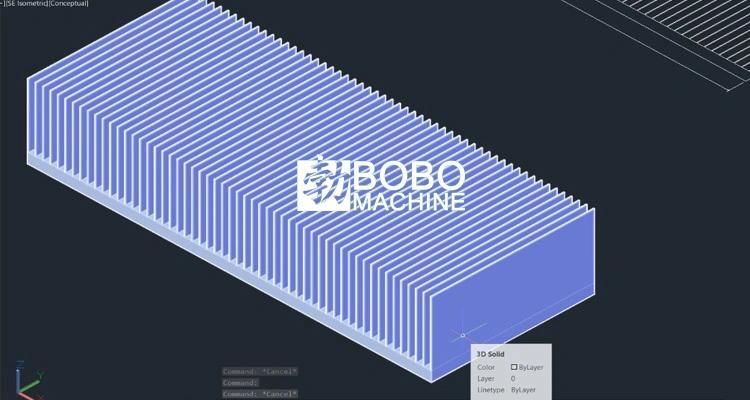

Aluminum Skive Fins Heat Sink Making Forming Machine for Copper Skive Fins

BOBO Machine Co., Ltd.- Trademark:bobo

- Origin:China

Base Info

- Model NO.:BO-3010

- Production Capacity:1000sets,Year

Description

Summary

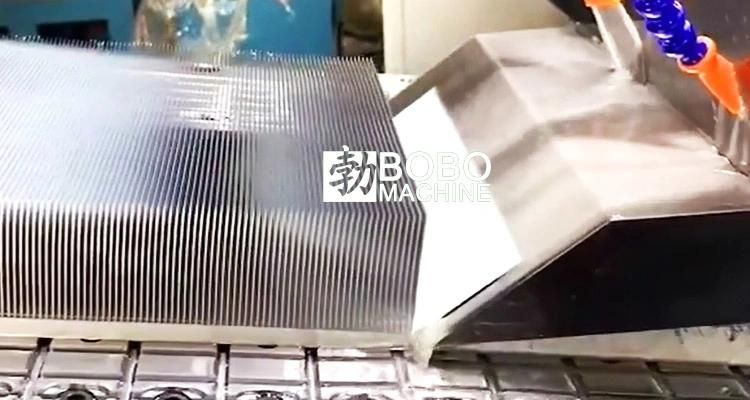

The advantage of precision cutting technology is that the endothermic bottom and the fin are formed in one body, the connection area (connection proportion) is large, there is no interface impedance, the fin is thick, can more effectively use the heat dissipation surface area; In addition, precision cutting technology can cut more heat dissipation area per unit volume (increased by more than 50%). The surface of the radiator fin cut by precision cutting technology will form coarse particles, which can make the contact surface between the radiator fin and the air larger and improve the cooling efficiency. The advantage of precision cutting is that the radiator belongs to the overall cutting molding, the heat sink fin and the heat sink base are combined as one, the heat sink produced by precision cutting technology does not exist the problem of thermal resistance on the interface, and the heat conduction efficiency is very high.

FAQ

1. Q: What is the power supply of the machine?

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.