Energy Saving Steel Shell Electric Induction Melting Furnace for Smelting Aluminum/Brass/Bronze/Copper/Iron/Steel

Foshan Hengyang Furnace Manufacturing Co., Ltd.- Control Type:PLC

- Customized:Customized

- Condition:New

- Automatic Grade:Automatic

- Certification:CE, ISO9001

- Type:Sand Casting

Base Info

- Model NO.:GW-1T

- Furnace Feacture:Hydraulic Pouring, Air Pollution Control

- Furnace Type:Steel Shell Furnace

- Power Supply Cabinet:Kgps Power Supply

- Furnace Capacity:1 Ton

- Melting Rate:1 Ton,Hour

- Rated Power:750kw

- Transformer Needed:800kVA

- Rated Voltage:380V, 3phase

- Input Frequency:50Hz

- Cooling System:Water Cooling System

- Working Temperature:0-1800 Degrees

- Associate Products:Cooling Tower, Lining Material, Ladle

- Delivery Time:30 Days

- Installation Guiding:Yes

- Provide Contruction Drawing:Yes

- Transport Package:Wood Packing

- Specification:2330*2080*1730mm, 4.5ton

- Trademark:HengYang

- Origin:China

- HS Code:851420009

- Production Capacity:150sets,Per Months

Description

KGPS power supply cabinet-1 set

capacitor-1 set

hydraulic station-1 set

tilting control device-1 set

crucible-1 piece

cooling cables-2 pieces

Field maintenance and repaire service-Yes

Technical document support( drawing, maintenance manual etc.)-Yes

Video technical support-Yes

Online support-Yes

per ton of material (KW)

capacity)

power

line voltage

line current

transformer

current

voltage

voltage

frequency

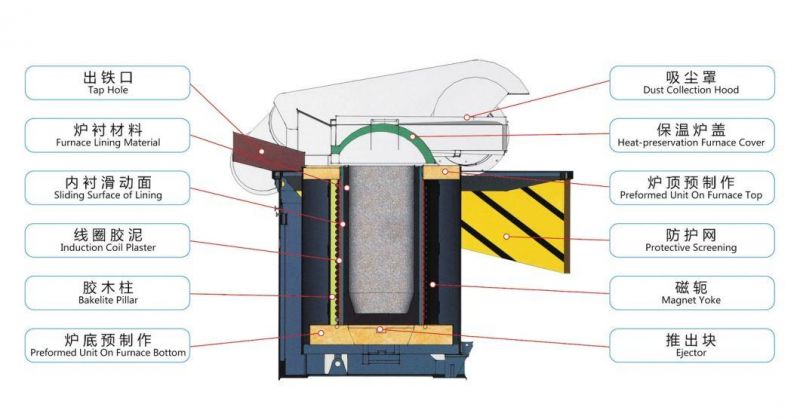

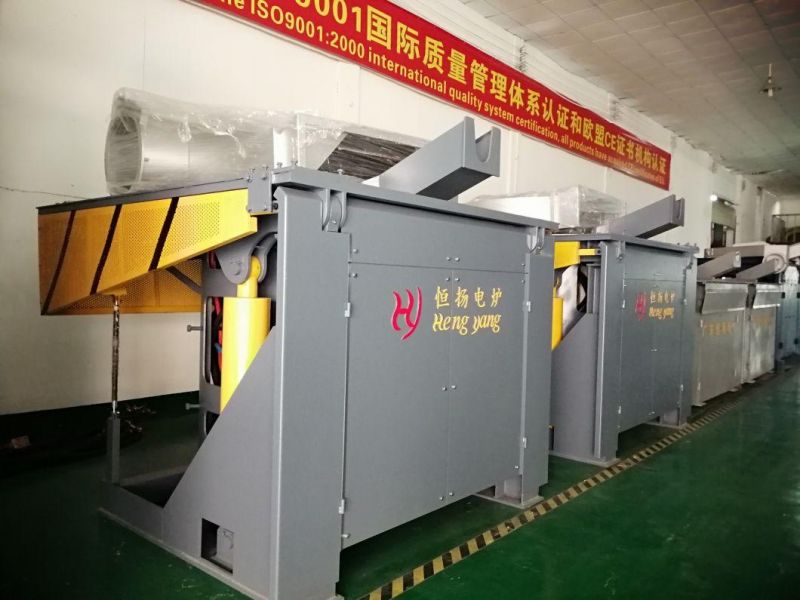

1- Steel shell furnace body

- Open furnace structure. The basic structure: with unique shock absorber and solid magnetic yoke, two cylinder with thick wall seamless rectangular steel tube is welded into one structure, being safer, firm, durable, high efficient. The upper end of the induction furnace can be disassembled to facilitate the replacement of the coil.

- Hydraulic tilting. Furnace can rotate around the pouring spout, and tilting with proportional control, through controlling buttons of hydraulic station and the handle of tilting control device . Its tilting angle is vertically at 95 degrees and it can stay in any position in the process of rotating, as well as to change titling speed to more quicker or more slowly. It uses the manual valve operation and double machine double pump, with remote manual control system. Some other company only have single pump control.

- Magnetic yoke. The sensor is enclosed with a magnetic yoke, covering an area is over 65%, so the leakage is small and achieve the maximum electrical efficiency. Compared with aluminum shell furnaces, steel shell furnace can save nearly 5% power consumption.

- Anti-fall protection device (for more than 2 ton capacity). During the process of tilting furnace, the anti-falling protective hood will be automatically raised to form a protective barrier to prevent the personnel from falling.

Optional Feactures:

- Furnace leakage alarm. It is equipped with an alarm device for preventing furnace from leakage, which can achieve safe production. It is a special dual leak-proof furnace alarm, when the lining getting thinner to a certain degree, a warning light will be given to alert the user that the lining needed to rechanged.

- Push-out lining system to rechange the lining with a automatic and more efficient way.

- Load cells to determine the mass of the metal.

- fume hood. Fume hood can absorb dust and exhaust gas generated during melting process through air, to meet the environmental requirements, working with dust removal system, they can reduce the exhausted gas emission.

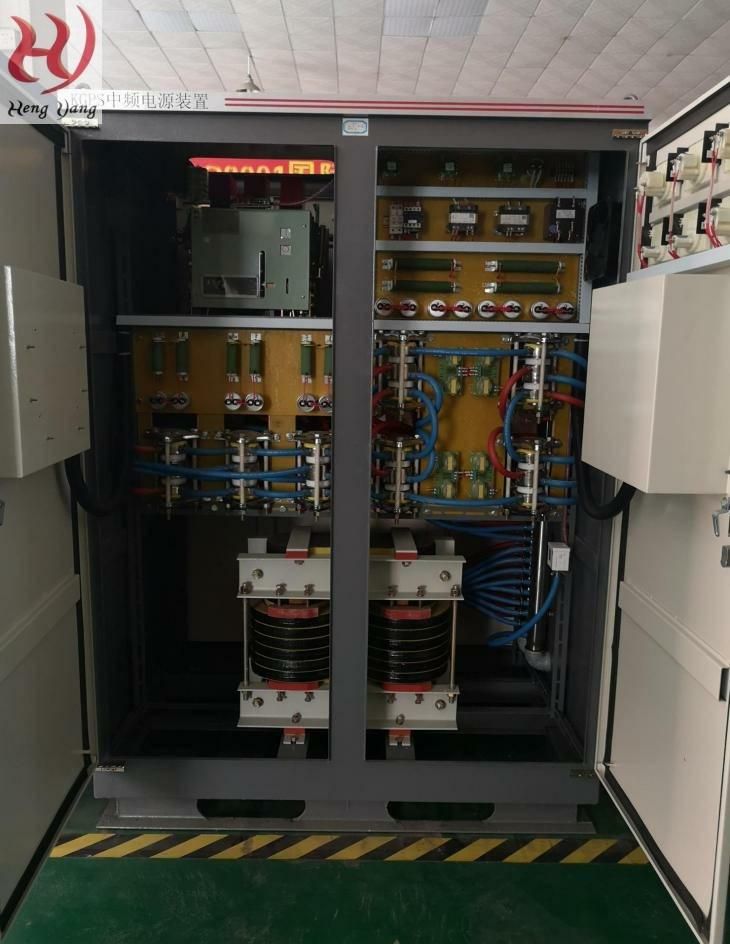

2- KGPS Power Supply Cabinet

a. Thyristor : Thyristors are purchased from the leading thyristor manufacturer in China. its thyristor have advantages of stable quality, strong current shock resistance, not easy to damage. It cost 20% to 30% higher than the same kinds of thyristor.

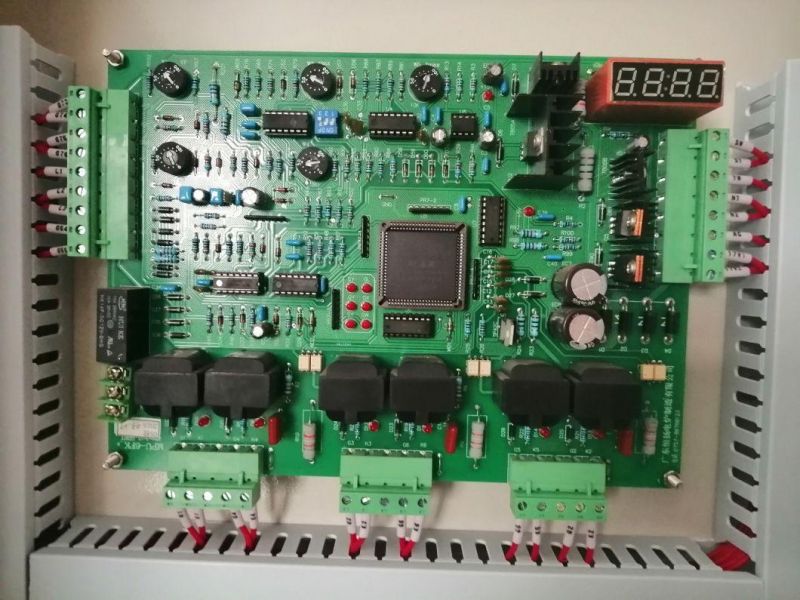

b. Main control board: ENGYANG control circuit boards are researched and manufacturing by HENGYANG independent research and development department. 20 years' researching and and improving keep them stand in a leading level in China. After manufacturing, the circuit boards will be tested by our professional quality inspection personnel one by one, to ensure its quality.

c. Circuit breaker:

The circuit breaker of HENGYANG power supply cabinet is purchased from a brand-name national manufacturing company, which was awarded as"China AAA enterprise", "Chinese famous quality products", "China top 100 enterprises" etc. So the quality of the circuit breaker is more reliable than others.

d. Capacitor box:

The capacitors are purchased from two domestic famous electric capacitor manufacturers. The capacitors have advantages of first class quality and strong over-voltage ability. It win consistent high praise from users.

4- Technical support1) Equipment design

Furnace will be customized to meet your production needing and environmental condition (maximum ambient temperate, humidity, altitude,etc) .

2) Drawings delivery

Technical drawing will be send to the buyer after geting the deposite, so the buyer can build basic contruction before the furnace arrived.

3) Acceptance check before delivery

a. The supply of the inspection equipment complies with the scope of supply and technical specifications in the technical agreement.

b. Check the mechanical actions of the equipment.

c. Safety interlock of equipment and alarm function test.

4) Installation & debugging & worker training

a. Cooperate with guidance to check the buyer installation work;

b. Internal and electrical wiring connections between equipment;

c. Site commissioning;, according to the actual equipment adjust to the best state;

d. Direct buyer operating personnel to the correct use of operating equipment;

e. Guidance on site security considerations;

f. To guide the buyer maintenance personnel troubleshooting methods;

g. Provide equipment specification;

5- Why choose us?1.Equipped with built-in circulating water cooling system, equipment can be long-term work, no cleaning; will not be damaged furring electrical power components; so-ting long machine life;

Other manufacturers require users to directly tap water or groundwater cooling machine power; regularly with detergents water pipe cleaning equipment; and often because of poor water quality, so that equipment, furring channels, resulting in poor heat electrical components being blocked or damaged;

2.Configure automatic circuit breaker, with a reliable protection

Equipment power supply short circuit, open circuit, lack phase, power outages, discharge, and other circuit abnormalities are able to quickly and automatically cut off the power supply; in a timely manner to the equipment and network protection. To ensure the safety of the production operator.

Other manufacturers in general only with simple switch or without. They asked users to protect themselves with a fully functional power distribution equipment. Otherwise, there is short circuit, lack phase, or other circumstances occur. Will be because there is no protection, prone to accidents.

However, our equipments carry good protective function even without switch board prepared by the users.

3.One of the largest enterprises in the industry in Guangdong

We are devoted to independent R&D as well as production. A rich variety of finished products and half-finished products with complete specifications and spare parts enable us to realize fast delivery. In addition, the independent after-sales department will provide follow-up services regularly as to all the products. Furthermore, many of our engineers have been engaged in the industry for over 20 years while 80% of the intermediate-frequency equipment manufacturing companies had not yet been established15 years ago.