Powder Coating System with Booth Oven and Spray Gun

Hangzhou Kafan Machinery & Equipment Co.,Ltd.- Type:Powder Coating Equipment

- Coating:Powder Coating

- Substrate:Steel

- Certification:CE, ISO

- Condition:New

- Booth Internal Size:L1500*W2300*H1500mm

Base Info

- Model NO.:COLO

- Oven Internal Size:W1600*H1800*D1400mm

- Oven Source:Electric

- Warranty:12month

- Customize:Size for Oven and Booth Could Be Ordered

- Transport Package:Carton or Wooden Box

- Specification:Manula

- Trademark:COLO

- Origin:China

- HS Code:8424899990

- Production Capacity:500sets,Month

Description

Powder Coating Booth

Powder coating is take place in the coating booth.

2315 coating booth includes: PLC controller,4 counts filters,fan motor,compressed air tank,hanger,powder recovery tank,solenoid vale,spray booth body.

Introduction:

This new powder coating booth with PLC controller,could control the powder coating booth more accurate.we could provide you the powder coating booth that will fit your needs. the powder coating spray booth fans draw air through filters . as the cartridge filters load,air flow decreases and the negative pressure rises within the air handler. a timer activates a system of air purging valves that clear the cartridge filters of the accumulated powder to ensure max filter life.

Features:

-Durable, long-life powder-coated steel structure with high-quality galvanized canopy and floor

-Low-profile booth base eliminates operator platforms

-Requires only quick, easy connect electrical and pnematics to start production

-Smooth inner surface easy clean

Powder Curing Oven

This Powder coating oven used for curing the workpiece which has been spraying during the powder coating. When a thermoset powder is exposed to elevated temperature, it begins to melt, flows out, and then chemically reacts to form a higher molecular weight polymer in the surface of the workpiece.

Features:

-COLO powder coating ovens are designed to safely and efficiently cure previously applied powder coating media.

- Our energy-efficient designs save fuel and get to temperature quickly.

-Standard and custom sizes range from small Lab units to large heavy equipment ovens and conveyorized curing systems.

- All our batch powder coating ovens feature premium 100mm thick insulated wall and roof panels.

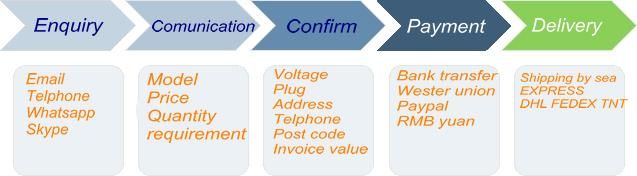

Packing & Delivery

-Packing: Carton and plastic bag

-Delivery: 20 work days after get the payment

If you are interested in our products,please send us enquiry.