C Purlin Roll Forming Machine (5mm)

Zhangjiagang City Saibo Science & Technology Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Electric

- Feature:Automation

- Certification:ISO9001, CE

- Warranty:12 Months

Base Info

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Name:Purlin Roll Forming Machine

- Drive:by Chain

- Transport Package:Sea Packing

- Trademark:SAIBO

- Origin:Jiangsu, China

- HS Code:84552210

- Production Capacity:300sets,Year

Description

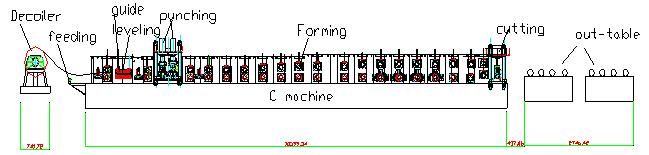

2. The Chart of Process Flow

Un-coiler-Leveling -Punching-Roll Forming-Cutting-out table

3. Specification of Components

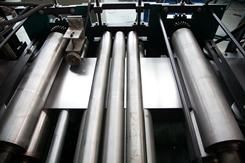

- Flattener roller: upper is 3 rollers, down is 4 stations(total is 7 rollers)

- Flattener roller material: SAE 1045 thermal treatment hardness 48-52 HRC.

- The punches and dollies will be CR-12, hardness HRC 58-62 and chrome coating.

- The whole punching operation should be automated and controlled by a program installed in the PC which is located in the operator's console.

- Hydraulic power: 7.5kw

- Roll station:14stations +1 station of torque head

- Roller material:Gcr15, 58-62,HRC hardness and chrome plated surface

- Shaft diameter: ¢120mm material: SAE1045

- Main frame by 350H beam welding

- Machine structure:wall panel

- Drive system: by chain

- Machine adopt hydraulic post cutting system.

- Cutting power by hydraulic, 7.5KW

- Cutting after forming: Cut the sheet after roll forming to required length

- Cutting motion: The main machine will stop when cutting, after the motion the machine will continue automatically.

- Material of blade:Cr12 with heat treatment 58-60°