High Speed Coil Nail Collator for Coil Nail Making, Coil Nail Welding Machine in India

Wuxi Shenda Nail Machinery Factory- After-sales Service:Engineer Traning Service

- Type:Forging Operation

- Forging Forming Method:Mold Forging

- Power Source:Pneumatic

- Feature:Automation

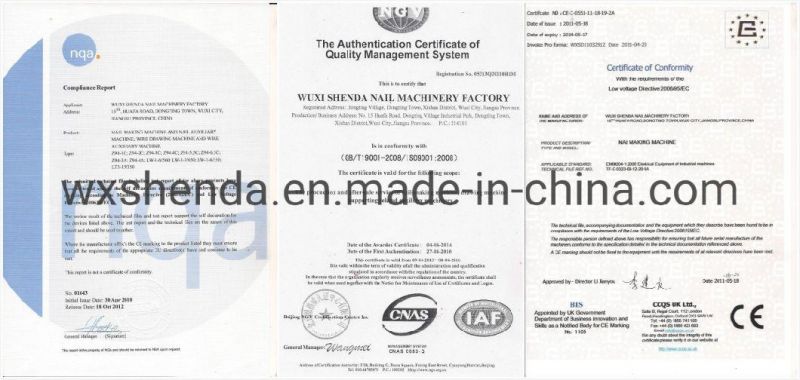

- Certification:CCC, ISO9001, CE

Base Info

- Model NO.:THN

- Warranty:12 Months

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Transport Package:Suitble for Shipping

- Specification:3100*1130*1500mm

- Trademark:Shenyida

- Origin:Wuxi China

- HS Code:8463300000

- Production Capacity:100PCS,Month

Description

Basic Info.

Model NO. THN Warranty 12 Months Customized Customized Advantage Easy to Maintenance Condition New Transport Package Suitble for Shipping Specification 3100*1130*1500mm Trademark Shenyida Origin Wuxi China HS Code 8463300000 Production Capacity 100PCS/MonthProduct Description

Our factory:

Wuxi shenda nail machienry factory professional manufactures High speed coil nail welding machine,nail making machine, wire drawing machine and the accessory equipments since 1995

Capacity 1000pcs per year, customers cover Africa ,middle East, Asia,and latin-America ariea.

Our company has CE, ISO9001 certificate and our engineer arrange for machine accommodation in customer's factory.

Advatage product:High speed coil nail making machine,Roofing nail making machinery;Blind rivet nail making machinery;Concrete nail making machinery;Barbed wire machine;Coil nail welding machine;High speed rolling machine

27 years machine manufacturer experience.14 years exporting experiance with more than 200 companises customers.

High Speed Coil Nail Collator

The High speed coil nail welding machine produced by our company is a fully automatic high-frequency high-speed welding equipment.

During operation, the iron nails are placed in the feeding hopper and automatically unloaded. The iron nails are arranged in order by the vibrating plate, and then enter the nail wheel through the unloading track, and then welded into coiled nails by two copper-plated welding wires, and then automatically dipped in paint to prevent rust and bake. Drying and counting are automatically rolled into rolls, and automatically cut according to the set count of each roll. The finished product can be produced by the operator after packing the finished product into the box.

The equipment includes a host, a vibrating plate, a large hopper, and a wire rack.

WIth more than 20 years developed ,we have full automatic packing machine connect with the high speed nail making machine,pls feel free to contact us for more information.

Coil nail making Process

| Model THN-1 | High speed coil nail welding machine |

| Range of Nail Dia.: | 1.8mm-4.0mm |

| Range of Nail Length: | 25mm-130mm |

| Output: | 800-2000pcs/min. |

| Rated Power: | 8kw |

| Power of Nail Feeding System: | 0.75kw |

| Power of Welding System: | 20kw, 1000-2000A |

| Power Supply: | 3 phases AC 380V 50-60HZ |

| coil nail welding angle | 15/16degree |

| coil nail welding wire diameter | 0.6/0.7/0.8mm |

| PLC brand | Japan Omron |

| Touch panel brand | TaiWan WEINVIEW |

| convetor brand | Japan Omron |

| replay brand | Japan Omron |

| Packing: | packed in 2 wooden cases |

| Packing Size: | 3000X1500X1800mm |

| 2000×1200×800mm | |

| Weight: | 1600kg |

Machine packing &Delivery

Our ISO9001 and CE certificate

FAQ:

1.Whast is the material for coil nail?

the material we use low carton steel Q195/SAE1006/1008/1010/1012,then we need make nail by nail making machine .and if you need nail shank with screw or ring shape ,we need use high speed thread rolling machine to make shank with screw or ring shape.At last,our high speed coil nail welding machine will weld the nail in coil.

2.What is the mould size and life?

The mould we use on the high speed coil nail welding machine need order to make according to your nail diameter and usually mould life could last 12month.

3.How about the machine install and operation?

we have machine video for how to intall and operate our machine,and we are also use wechat/whats app to help you overcome the problem when you meet.

4.Do we need buy many spare parts for this machine?

As the more than 20 years developed,we simple our systerm and electrical parts,which less the maintain cost and easy to replace the machine electrical parts as soon as it ware and tear.