Automatic Easy Operation Building Material Metal Roofing Galvanized Corrugated Steel Sheet Tile Making Roll Forming Machine

Hangzhou Zhongyuan Machinery Factory- After-sales Service:Provide

- Type:Rolling Machine

- Forging Forming Method:Cold Roll Forming

- Power Source:Electric

- Feature:Automation

- Certification:ISO9001, CE

Base Info

- Model NO.:tile making machine

- Warranty:12 Months

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Coil Thickness:0.5-0.6mm

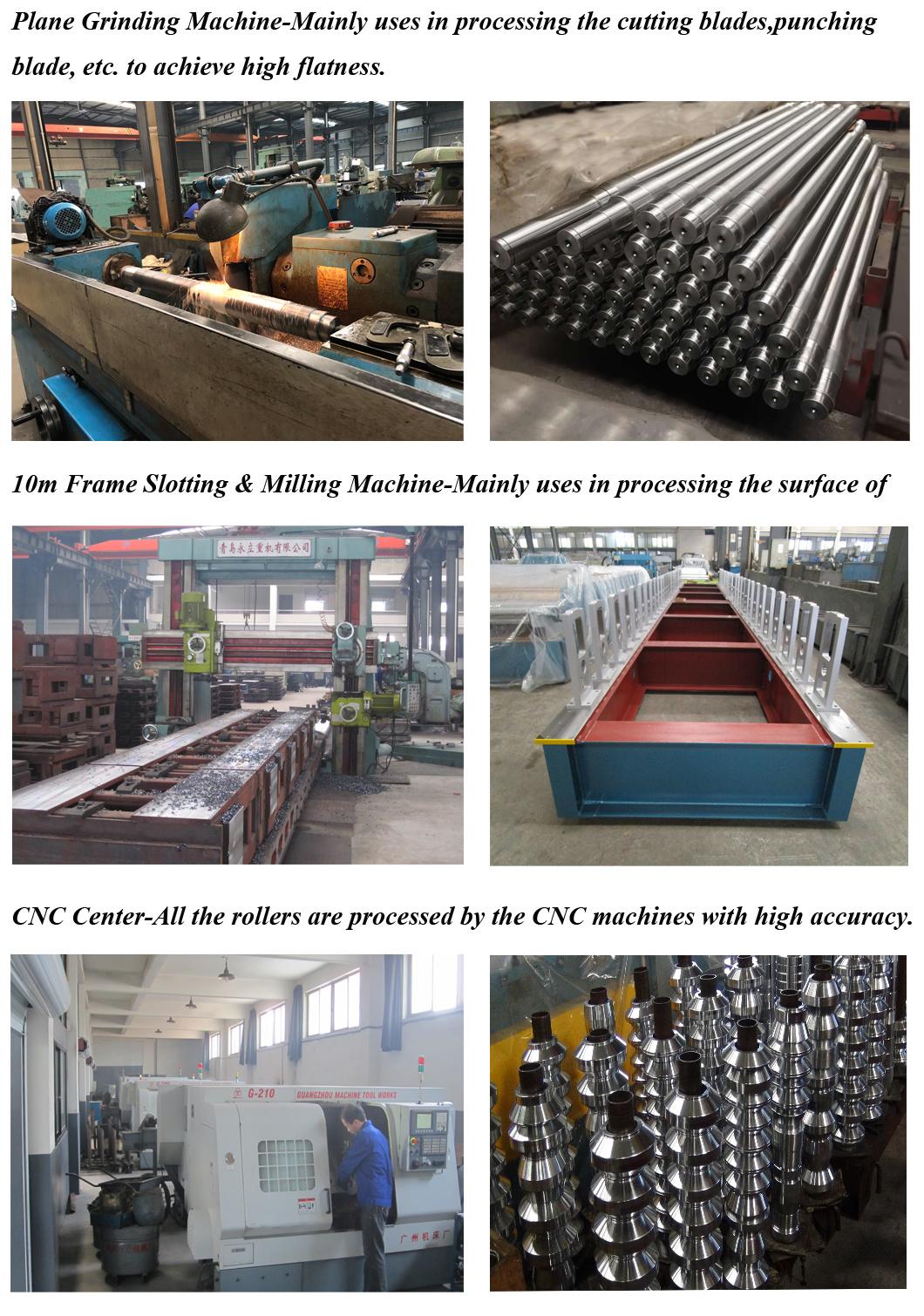

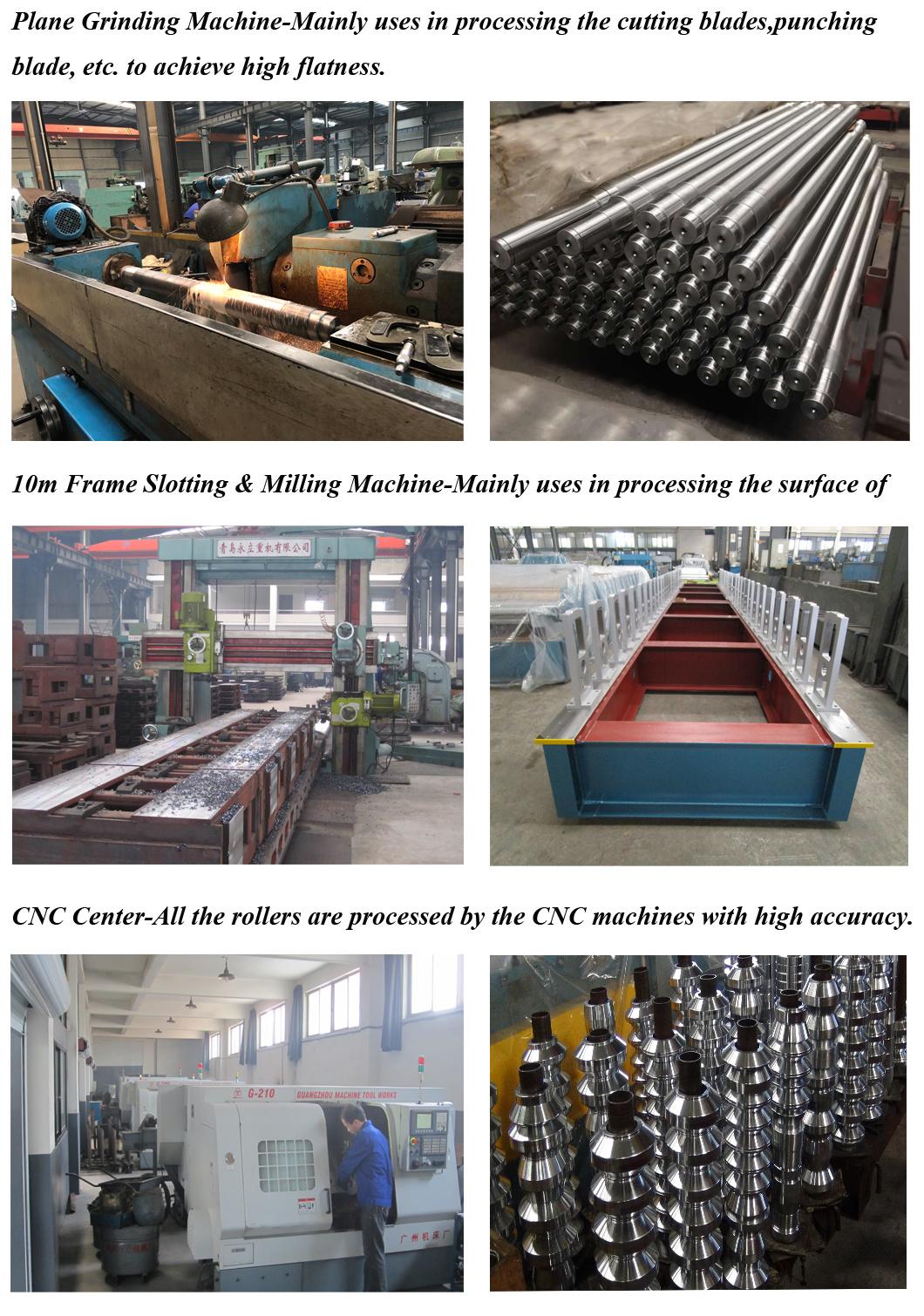

- Roller Grinder Milling:Cr12 Mould Steel with Quench Treatment

- Diameter of Shaft for Rollers:72mm

- Main Power:5.5kw

- Voltage:380V,50Hz,3phase

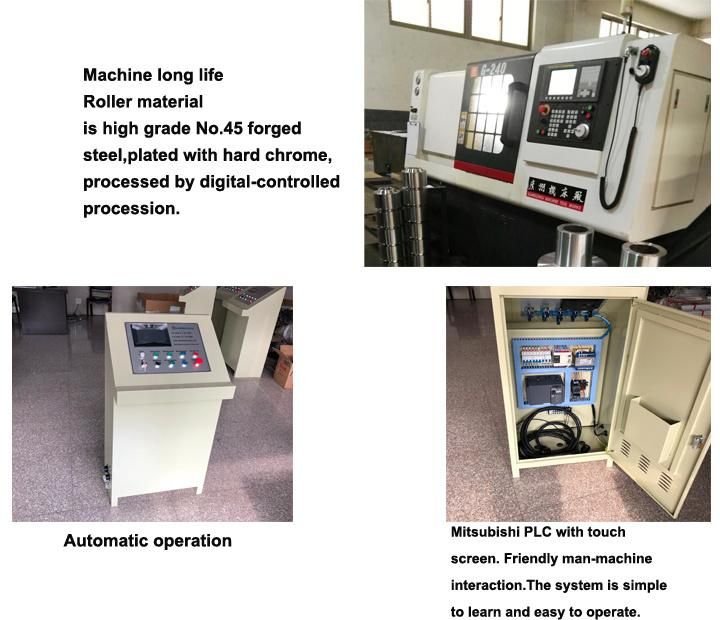

- Control System:Mitsubishi PLC

- Transport Package:40gp

- Specification:CE SGS BV

- Trademark:Zhongyuan

- Origin:Hangzhou

- HS Code:84552210

- Production Capacity:10sets,Month

Description

Overview

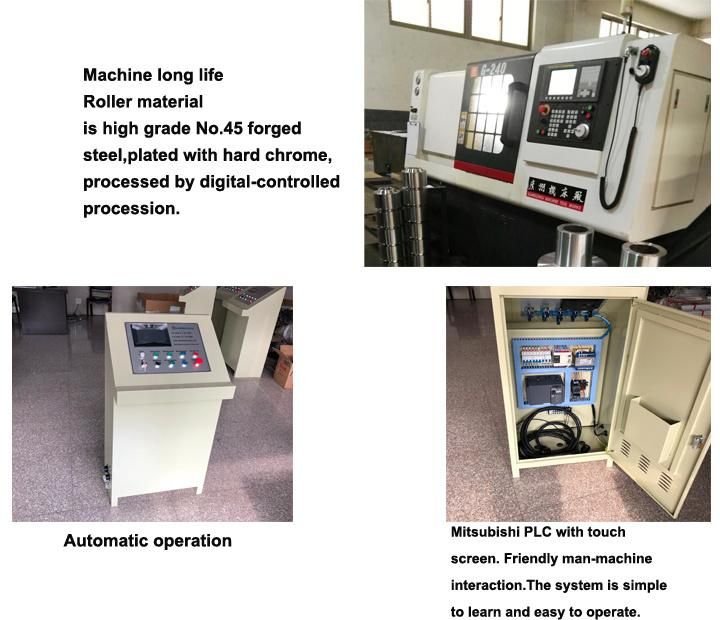

2. Introduced Mitsubishi PLC with touch screen to machine controll system.

3. Need only one worker (minimum) to operate

4. Roller cover with 0.05mm chrome, ensure lifetime>10years

5. Cr12 mould steel cutter with quenched treatment. Blade with heat treatment.

6. Product cut-to-length.

7. 72mm diameter solid steel shaft

Specification Material Type Color steel sheet Thickness(mm) 0. 5 -0. 6 Yield strength(mpa) 235 -345 Roller material 45#Chrome steel Forming speed(m/min) About 1500-2000mm/min or 4-5m/min. For option Step distance Adjustable according to requirement (>=250mm) Speed adjusting mode AC Frequency Transmission way Cutting mode Hydraulic cutting Cutter material Cr12 mold steel Length measurement Encoder Control mode Mitsubishi PLC Operating mode Button + Mitsubishi Touch screen Main motor power(kw) 5.5KW (Depend on final design) Hydraulic station power 7.5K W (Depend on final design) Total power(kw) 11KW Uncoiler's loading capacity Max. Capacity: 5000kgs

(can be increased to be 10T) Machine`s size About 8.45*2.1*1.73m (Depend on final design) Machine weight About 11100kgs

Components of machine:Decoiler 1set Feeding & guiding device 1set Main roll forming machine 1set Pressing device 1set Hydraulic cutting system 1set Controlling system 1set Run out table 1set

Process flow:

Decoiler -- Feeding & Guiding -- Roll Forming-- Pressing--Hydraulic Cutting - Product to Run Out Table

2. Main machine body and decoiler is load naked (tighten to container with steel wire rope).

3. Spare parts and operating tools are loading in tooling box.

After Sales Service

Get Free:

Provide profile drawing & design technical support FOR FREE!

Website:cnzhongyuan.en.made-in-china.com

Factory Address:No. 228 Yongli, Nanyang Street, Xiaoshan District, Hangzhou, Zhejiang, China

Our Advantages

1. Designed by 15 years experienced R&D members with lifetime seivices

2. Introduced Mitsubishi PLC with touch screen to machine controll system.

3. Need only one worker (minimum) to operate

4. Roller cover with 0.05mm chrome, ensure lifetime>10years

5. Cr12 mould steel cutter with quenched treatment. Blade with heat treatment.

6. Product cut-to-length.

7. 72mm diameter solid steel shaft

Product Parameters

Item

Gear-box transmission (optional)

(can be increased to be 10T)

Components of machine:

Process flow:

Decoiler -- Feeding & Guiding -- Roll Forming-- Pressing--Hydraulic Cutting - Product to Run Out Table

Packaging & Shipping

1. One 40feet container for loading one set machine with mechanical decoiler.

2. Main machine body and decoiler is load naked (tighten to container with steel wire rope).

3. Spare parts and operating tools are loading in tooling box.

Hot Product

Company Profile

Our Clients

FAQ

After Sales Service

Get Free:

Provide profile drawing & design technical support FOR FREE!

Website:cnzhongyuan.en.made-in-china.com

Factory Address:No. 228 Yongli, Nanyang Street, Xiaoshan District, Hangzhou, Zhejiang, China