Cleaning Equipment for Drum Castings Used in Casting

Qingdao Ding Li Machinery Co., Ltd.- After-sales Service:After-Sales Service

- Warranty:One Year Warranty,

- Control Type:PLC

- Customized:Customized

- Condition:New

- Automatic Grade:Automatic

Base Info

- Model NO.:L3214

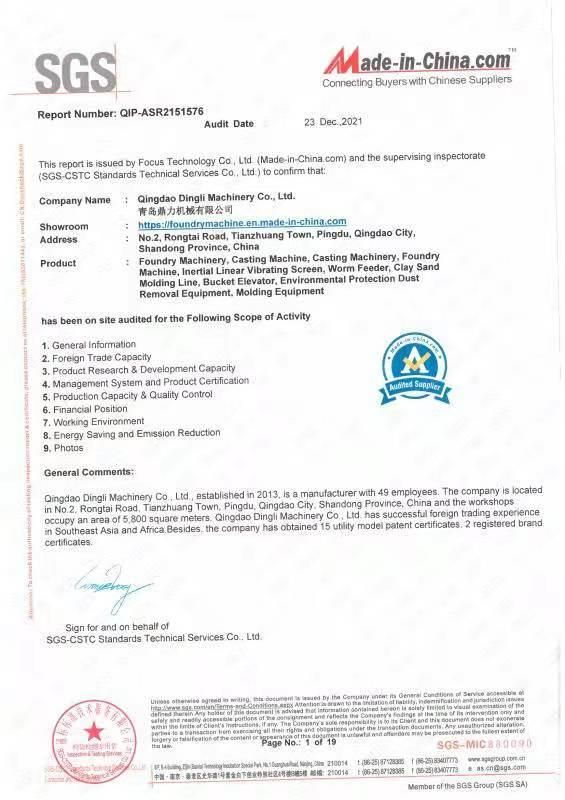

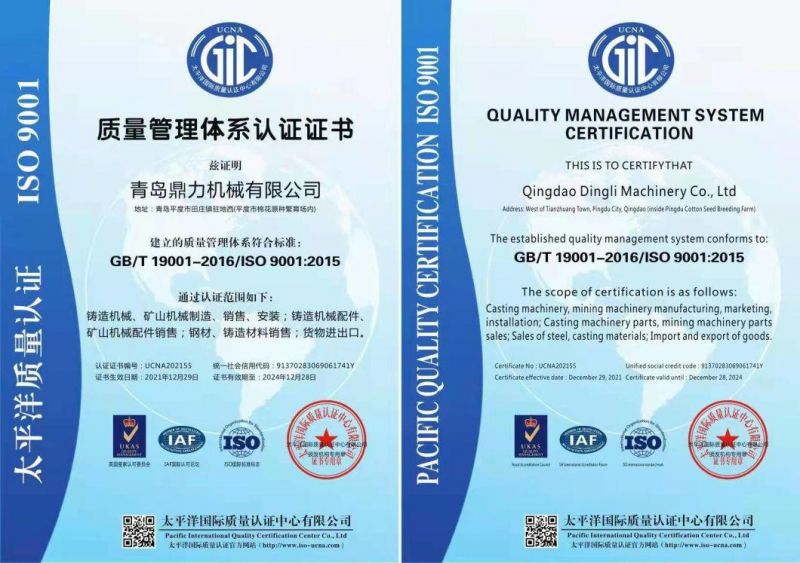

- Certification:CE, RoHS, GS, ISO9001

- Type:Sand Casting

- Transport Package:Custom

- Trademark:DL

- Origin:Qingdao, China

- HS Code:8474802000

- Production Capacity:500

Description

Basic Info.

Model NO. L3214 Certification CE, RoHS, GS, ISO9001 Type Sand Casting Transport Package Custom Trademark DL Origin Qingdao, China HS Code 8474802000 Production Capacity 500Product Description

Qingdao Dingli Machinery Co., Ltd. is located in the beautiful seaside-Qingdao Pingda. the company set research,manufacturing,installationandcommissioning,after-sales service in one. It mainly produces resin sandproductionline,clay sandproductionline,coated sandproductionUne equipment, various sand treatment single machine equipment,etc. The company has advance casting machinerymanufacturinganddevelopmenttechnology,theproductionof products can full meet theinternationaland domestic market demand.The company has excellent design and R&D team, skilledconstructionteam, domestic leadwi casting equipment design concept,perfect after-sales service system, is willing to cooperate with the majority of foundryenterprisesto create a better tomorrow.

In line with the"down-to-earth, integrity-based, focus on service,continuousinnovation"businessphilosophy,throughcontinuousefforts. We use our own efforts and focus on thedevelopmentof a series of perfectprocessingequipment to meet the different needs of users.

Working principle:

Working principle:When the cast with sand box removed enters the cylinder body and rotates to a certain height with the cylinder body, it falls under the cylinder body by its own weight. Under the action of constant impact and friction between each other, the sand mold is separated from the casting and arrives at the grid part of the cylinder body along the direction of spiral pieces. The sand enters the old sand system and the casting is discharged from the discharge port.

Model | Parameters Name | (t/h) Productivity(t/h) | (kw) Power(kw) | (m3/h) Dust removal air volume (m3/h) |

| L3214 | Sand cooling roller | 16-25 | 11 | 8000-12000 |