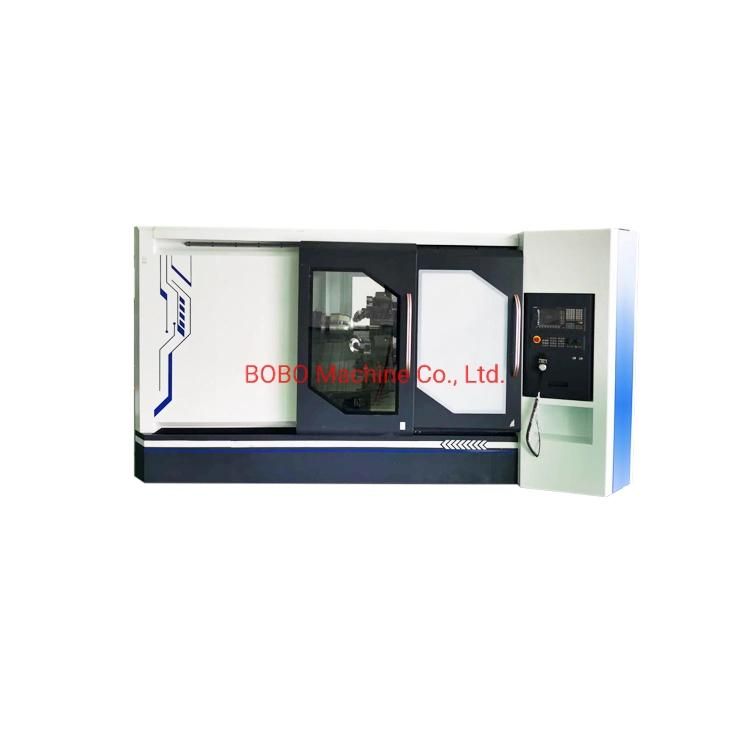

CNC Metal Hot Spinning Machine for Cookware Aluminum Stainless Steel Bottle Necking Reducing Machine

BOBO Machine Co., Ltd.- After-sales Service:5 Year

- Warranty:1 Year

- Structure:Horizontal

- Spinning Strength:High Power Spinning

- Pressure Supply Type:Hydraulic Pressure

- Metal Material:Alloy

Base Info

- Model NO.:XY-800

- Spinning Deformation Condition:Hot Spinning

- Spinning Wheel Number:Double

- Finished Product:Wheel Rim

- Finished Product Shape:Circle

- Transport Package:Wooden Cage

- Trademark:BOBO

- Origin:China

Description

Basic Info.

Model NO. XY-800 Spinning Deformation Condition Hot Spinning Spinning Wheel Number Double Finished Product Wheel Rim Finished Product Shape Circle Transport Package Wooden Cage Trademark BOBO Origin ChinaProduct Description

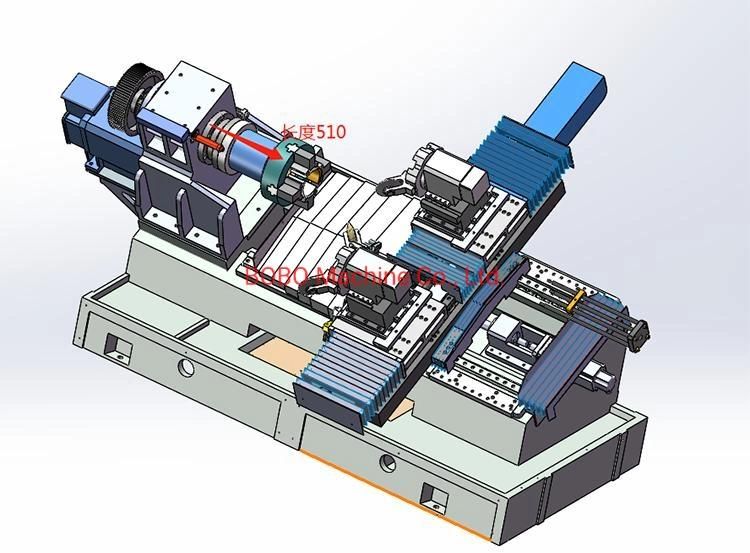

I SummaryThe CNC metal spinning machine XY-800 applies to aluminum plate, cooper plate, iron plate, stainless steel plate and steel plate spinning processing of lighting, cooker, art and craft. With horizontal high strength casting composite structure and digital program control, can realize manual adjustment, semi-automatic, automatic operation mode. The equipment function and practical, strong professionalism, high production efficiency, can finish the bucket, conical, parabolic, horn, warhead, etc. Series of products of mass production and trial production tasks, but also in the same machine tools to complete mold finish turning, finished products, trimming, flanging, crimping, reducing, car shape and thread rolling, fine processing, and other functions. It is suitable for spinning aluminum (alloy) plate, copper plate, stainless steel and copper plate and other materials.

II Main Function:

- Servo spindle can be step-less speed regulated and controlled by programming.

- CNC programmable control of radial feed of rotary wheel.

- CNC programmable control of axial feed of rotary wheel.

- Tail-top speed is controlled by servo motor, CNC programmable control.

- CNC control system from Siemens, Germany. (Mode: 808)

- The flame heating system is optional according to product requirements.

III Main technical data

| Parameter | unit | Data |

| Maximum turning diameter of overpass bracket | mm | 550 |

| Maximum sheet diameter | mm | 800 |

| Double center distance (distance from spindle center to stern top center) | mm | 1000 |

| Main motor | kW | 18.5 |

| The X axis stroke | MM | Unilateral 400 |

| Maximum thrust on the X-axis | KN | 37 |

| Maximum X velocity | Mm/min | 7500 |

| The Z axis stroke | MM | 600 |

| Maximum Z thrust | KN | 56 |

| Maximum Z velocity | Mm/min | 6000 |

| Spindle speed | The RPM | 50-1500. |

| Maximum tail top force | KN | 30 |

| The tail cap trip | mm | 500 |

| Number of tools (rotary wheel) | a | 6 + 6 |

| Processing aluminum thickness | mm | 0.5-6 |

| Processing ordinary steel thickness | mm | 0.5 3 |

| Machined stainless steel thickness | mm | 0.5-2.5 |

| Machine tool dimension | mm | 4060 * 2000 * 1600 |

| Main shaft flange connection mode | GB | A2-8 - |

| Machine weight | KG | 7000 |