H13 (4Cr5MoSiV1) Hot Piercing Plug for Hot Rolling Seamless Pipes Production

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Good Design:Water-Jet for Long Service

- Hardness:as Requirement

- Application Range:Low Carbon and High Chromium Alloy Steel Pipes

- Transport Package:Plywood Case

- Specification:as the drawing

- Trademark:FANGLE

- Origin:China

- Production Capacity:50000tons,Year

Description

Basic Info.

Model NO. as the drawing Good Design Water-Jet for Long Service Hardness as Requirement Application Range Low Carbon and High Chromium Alloy Steel Pipes Transport Package Plywood Case Specification as the drawing Trademark FANGLE Origin China Production Capacity 50000tons/YearProduct Description

H13 (4Cr5MoSiV1) hot piercing plug for hot rolling seamless pipes productionDescription

H13 piercing plug with Mo inserted or welded has the best performance.The product density and strength are higher, and wear resistance becomes much better. Most importantly the life of the product extends extremely much.In the process of piercing or rolling the roughness on the inner wall of steel pipe can be enhanced.

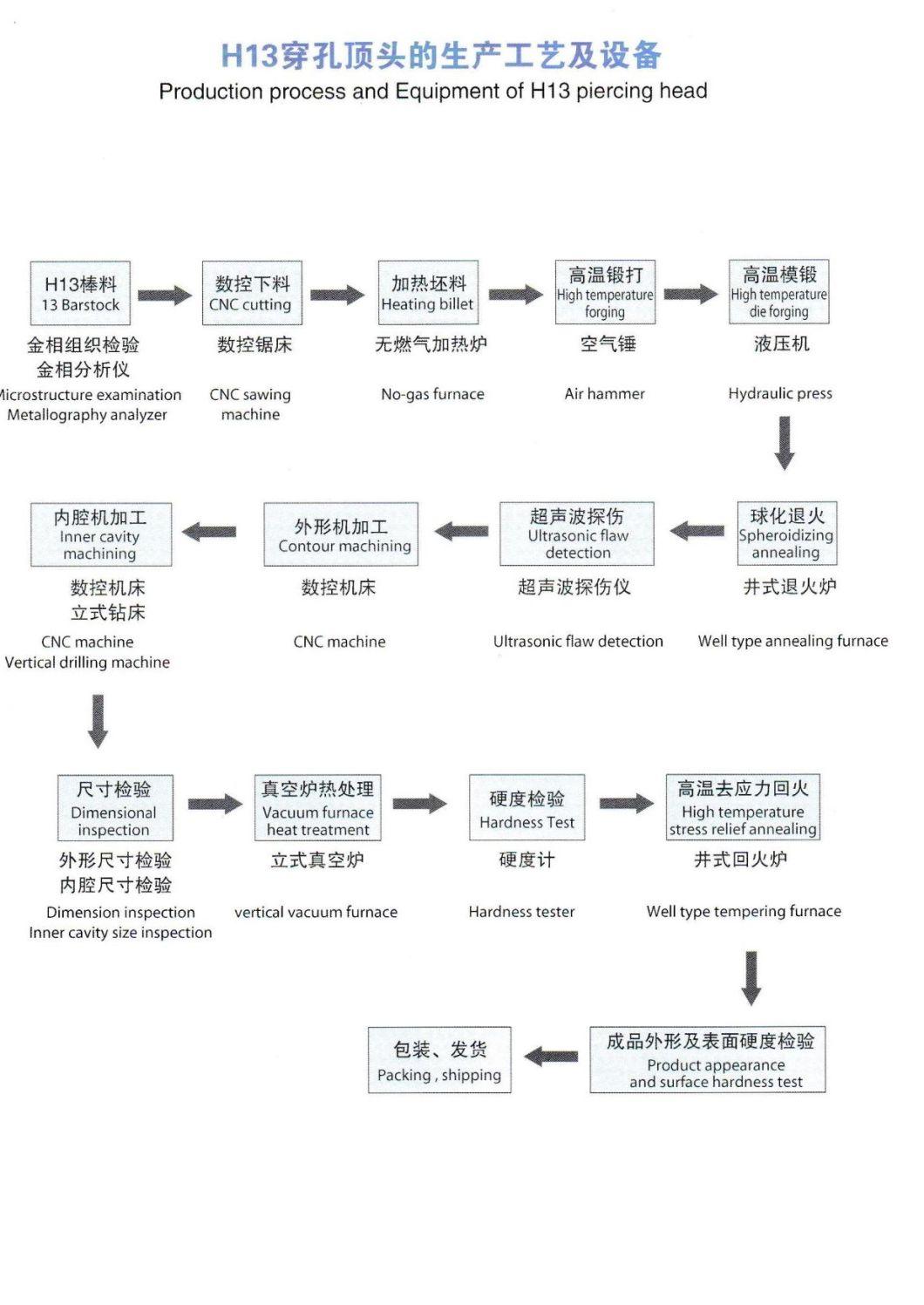

Production process

Products show

Customer Visit