Zinc Plating Equipment Chrome Electroplating Machine Nickel Rack Electroplating Equipment

Junan Tongda Electronic Equipment Factory- After-sales Service:Yes

- Voltage:380V

- Automatic Grade:Automatic

- Warranty:1 Year

- Certification:GS, CE, ISO

- Control System:Portable , Pushing , Remote , PLC Programee

Base Info

- Model NO.:TD-H

- Equipment Mode:Portable , Manual,Semi-Automatic,Full-Automatic

- Application:Metal , Ss , Brass , Iron , Aluminum Plating

- Usage:Zinc , Nickel , Chrome , Anodizing , Copper

- Pre-Treatment Step:Ultrasonic,Electronic,Heating Degreasing

- Pre-Treatment Machine:Ultrasonic Clean Machine , Polishing Machine

- Exteranl Equipment:Rectifier , Filter , Water Chiller

- After-Treatment:Oven , Dry Machine

- Rectifier:380V 50Hz , 3pH

- Rectifier Spec:1000A 12V , 2000A 12V and etc.

- Material:PP , PVC , Ss Plate

- Crane Lifting:Electronic Hoist , Manual , Automatic

- After-Service:Free Spare Parts, Field Installation

- Transport Package:Plywood Package and Ocean Shipping

- Specification:Customized

- Trademark:TONGDA

- Origin:Linyi China

- HS Code:8543300090

- Production Capacity:5-10 Sets Per Month

Description

Basic Info.

Model NO. TD-H Equipment Mode Portable , Manual,Semi-Automatic,Full-Automatic Application Metal , Ss , Brass , Iron , Aluminum Plating Usage Zinc , Nickel , Chrome , Anodizing , Copper Pre-Treatment Step Ultrasonic/Electronic/Heating Degreasing Pre-Treatment Machine Ultrasonic Clean Machine , Polishing Machine Exteranl Equipment Rectifier , Filter , Water Chiller After-Treatment Oven , Dry Machine Rectifier 380V 50Hz , 3pH Rectifier Spec 1000A 12V , 2000A 12V and etc. Material PP / PVC / Ss Plate Crane Lifting Electronic Hoist , Manual , Automatic After-Service Free Spare Parts, Field Installation Transport Package Plywood Package and Ocean Shipping Specification Customized Trademark TONGDA Origin Linyi China HS Code 8543300090 Production Capacity 5-10 Sets Per MonthProduct Description

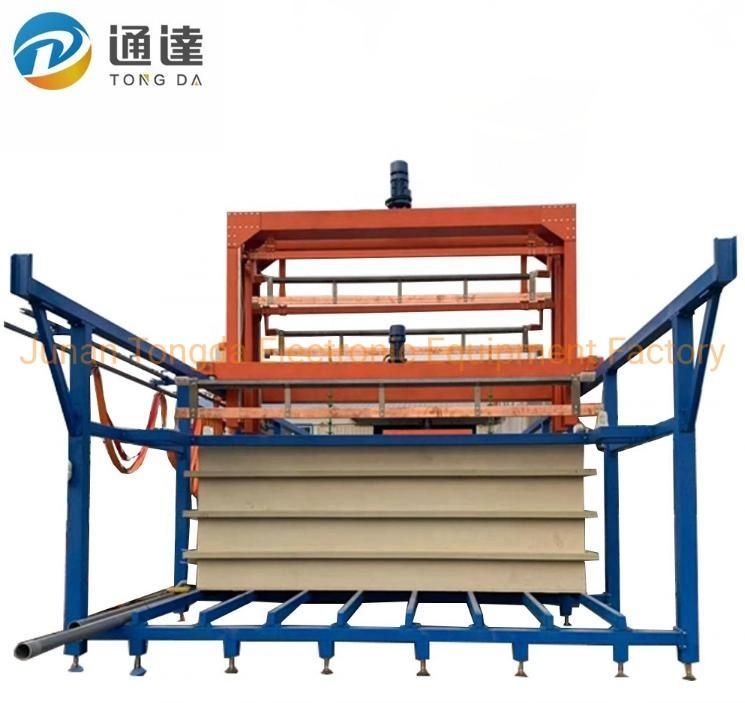

Zinc plating equipment chrome electroplating machine nickel rack electroplating equipment

Hang/Rack Electroplating Equipment

1. Automatic Gantry Type Hang Plating Equipment

Features:

(1)Its has mix function with full-automatic

and semi-automatic, with degree of

automatic

(2)High Productivity ,stable quality ,saving

time ,human and area

(3)Intelligent operating System:Controlled by PLC .Using the Man-Machine touched interface controlling panel,can

monitor and adjust the every process and

data.

Application:

Bulk metal and non-metal parts surface treatment including the machinery,car ,textile ,army and electronic industry.2. Semi-Automatic Hang Plating Line Features:(1)Using the remote controller . Easy to operate(2)Less investment and with little mechanical problem3. Manually Hang Plating LineFeatures:

(1)Advantage :Lowest cost, Easy to Operate.Manual lifted up and down

(2)Disadvantage: More human charge

SPECIFICATION OF ELECTROPLATING EQUIPMENT:

1. High quality raw material : 15mm PP(Polypropylene)/ PVC(Polyvinyl chloride) plate (Welcome customized )

2. The machinry frame : Steel body with anti-corrosion and resistant Epoxy painting .

3. Application for : Zinc plating ; Nickel plating ; Chrome plating ; Copper plating ; Gold plating ; Anodizing and etc.

4. Welcome customized : the electroplating line is non-standard , it is designed according to your products information .

5. Electroplating equipment mode :

Portable mode : the Plating barrel / hangers carried by hand .

Manual mode : there is crane lifting , pushing it by hand to up and down , go ahead and backward .

Semi-automtic mode : there is a automatic crane lifting , control by remote to up and down , go ahead and backward .

Full-automatic mode : there is a automatic crane lifting , control by PLC programme system to up and down , go ahead and backward .

6. Testing before delivery :

(1) Anti-leakage testing : We will fill the tanks with water after welding and before installation , the testing time last 72 hours .

(2) Runing testing : We will installed the equipment and operate it . Meantime , we will take the testing videos to the customer to confirm it .

7. Guarantee : one year ( We will replace the external equipment for free except the human damaged )

8. We are factory lied in Linyi city , Shandong province , China . We have the best price .

9. We have Export license , we can export to your area directly .

10. Surrounding equipments :

| Pre-treatment equipment | Ultrasonic degreasing equipment , Washing machine , Vibrating polishing machine |

| After-treatment equipment | Oven , Dryer |

| External equipment | Rectifier , Filter , Chiller |

| Water cycle system | Input and output plastic pipes and value |

| Exhaust system | Air cover, ventilation pipe, Exhaust fan , Acid mist tower, Air box |

EQUIPMENT DETAILS :

The electroplating equipment include the PP plating tank , Metal hangers , Crane lifting , Track and support , Anti-leakage PP plate , Anode plate holder , Copper plate , copper V-holder , PP V-holder and etc.

1. 15mm PP(Polypropylene)/ PVC(Polyvinyl chloride) plating tanks :

This is the main boday of electroplating equipment .

2. Plating barrel :

The barrel for barrel plating line , it is used for the small metal hardware which can do large mass production. for example , the nails , screw etc.

3. Metal hanger :

The hangers for rack/hang plating line . it is used for large metal parts

4. Crane lifting :

The manual crane and automatic crane .

EXTERNAL AND AUXILIARY EQUIPMENT :

PACKAGE & DELIVERY :

Package mode : by plywood or shipping by container directly .

Shipping : Ocean shipping

Lead time : 30-35 working days

FACROTY AND SERVICE:

This is our factory JUNAN TONGDA ELECTRONIC EQUIPMENT FACTORY which lie in Junan County , Linyi City ,

Shandong province . We are professional electroplating equipment manufacturer , zinc , nickel , chrome , copper, gold and etc.

plating equipment , welcome your inquiry .

1. Advanced technology

We have more than 13years manufacture experience , More than 80% of high-quality employees have many years of production technology experience

2. Multiple Quality Control

Double testing of semi-finished and finished products in the production process to maximize the quality of all cleaning machine.

3. Independent research and innovation

1) Cooperate with major R&D institutions to develop innovative products in response to market demand .

2) Independent research and development, we will create exclusive cleaning equipment according to the special needs of customers to meet the customization needs of customers.

4. Service assurance

We provide 7*24 hours multilingual services(Chinese, English, French, Russian,Arabic, Japannese,Spaish).DMS equipments: online failure analysis and maintenance system

WELL , ABOVE ARE THE DETAILS WHAT I WANT TO TELL YOU , OUR FACTORY , OUR COMPANY , OUR EQUIPMENT , OUR SERVICE , THIS IS A PROFESSIONAL TEAM , WELCOME YOUR INQUIRY .

AWAIT YOUR KINDLY INFORMATION !!!

BEST WISHES TO YOU AND YOUR FAMILY !!

THANK YOU !