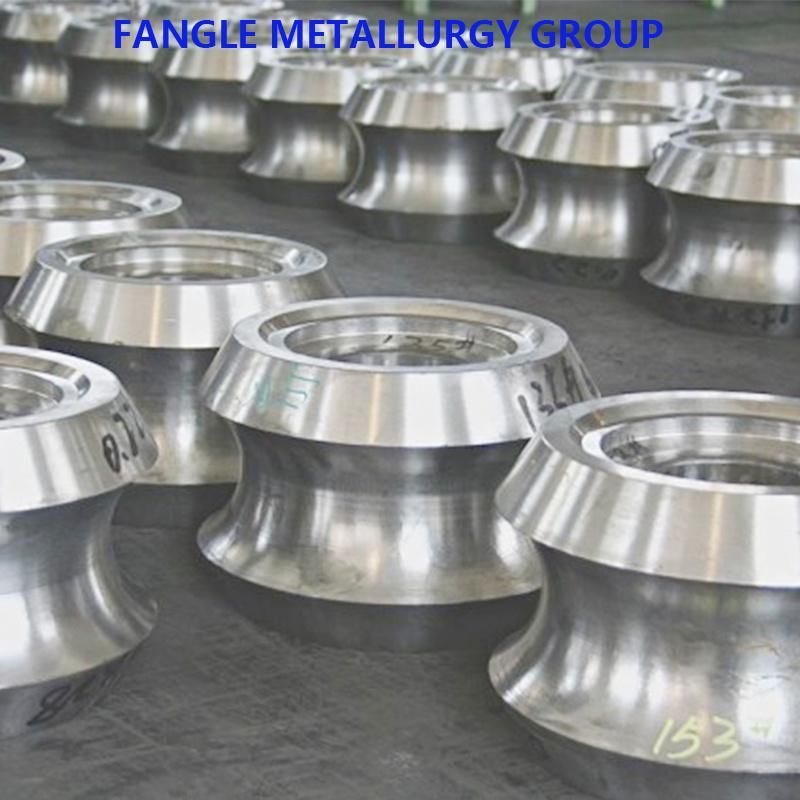

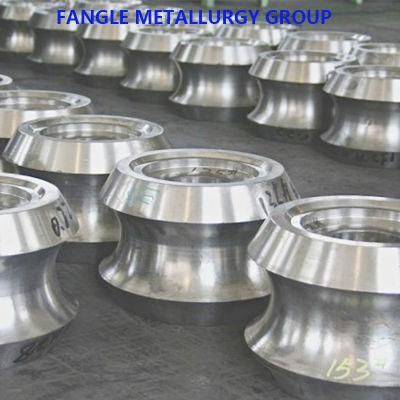

Stretch Reducing Mill Rollers for High Quality Seamless Steel Pipes

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Steel

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as required

- Transport Package:Woodern Case

- Specification:Export package

- Trademark:FANGLE

- Origin:China

- Production Capacity:15000 Tons,Year

Description

Basic Info.

Model NO. as required Transport Package Woodern Case Specification Export package Trademark FANGLE Origin China Production Capacity 15000 Tons/YearProduct Description

The steel tube rolled by pilger mill is reheated by heating furnace and then rolled by sizing rollers to get the more exact and higher precision dimension.Sizing roller machining accuracy will directly influence the sizing mill frame assembly accuracy and quality of seamless steel tube. Sizing roller adopt chilled nodular cast iron material.

The production process foresees:

element tests - intermediate frequency electric furnace smelting - centrifugal composite casting - lathe rough machining - heat treatment - CNC machine finishing - inspection - line cutting - packaging.

FANGLE monitor the whole process of quality control, and the sizing rollers manufactured by us have higher strength, higher precision and wearing resistance, longger service life.