Electrostatic Powder Coating Plant with Heat Insulation Curing Oven

Zouping Hongyuan Eco-Friendly Mechanical Technology Co., Ltd.- Type:Coating Production Line

- Coating:Powder Coating

- Substrate:Steel

- Certification:CE, ISO

- Condition:New

- Size:as Required

Base Info

- Model NO.:HY-PLD

- Area:as Required

- Output:as Required

- Pretreatment:with or Without

- Painting Method:Manually or Automatically

- Changing Colors:as Required

- Transfer Equipment:Automatically

- Curing Oven:Necessary

- Conveyor Type:as Required

- Control Box:English Panel

- Transport Package:Standard Package for Sea Shipment

- Specification:size as required

- Trademark:N,A

- Origin:China

- Production Capacity:100 Set Per Month

Description

Basic Info.

Model NO. HY-PLD Area as Required Output as Required Pretreatment with or Without Painting Method Manually or Automatically Changing Colors as Required Transfer Equipment Automatically Curing Oven Necessary Conveyor Type as Required Control Box English Panel Transport Package Standard Package for Sea Shipment Specification size as required Trademark N/A Origin China Production Capacity 100 Set Per MonthProduct Description

1.Powder coatingad's vantage over conventional liquid coatings

Powder coatings emit zero or near zero volatile organic compounds (VOC). Powder coatings can produce much thicker coatings than conventional liquid coatings without running or sagging. Powder coating overspray can be recycled and thus it is possible to achieve nearly 100% use of the coating. Powder coating production lines produce less hazardous waste than conventional liquid coatings. Capital equipment and operating costs for a powder line are generally less than for conventional liquid lines. Powder coated items generally have fewer appearance differences between horizontally coated surfaces and vertically coated surfaces than liquid coated items. A wide range of specialty effects is easily accomplished which would be impossible to achieve with other coating processes.

2.Powder coating line component:

Spray pre-treatment system(for option) : Dipping pretreatment with overhead crane, or fully automatic spraying pre-treatment.

Powder spraying booth: Automatic powder coating reciprocator, Manual powder coating and Semi-auto (Auto-powder coating with manual repairing spraying) are for your choice.

Drying tunnel oven(for option) : Drying oven which drying the water after pretreatment is designed according to customer actual conditions.

Curing tunnel oven : Tunnel curing oven, bridge type curing oven, batch type on the line.

Conveyor system : Closed-circuit conveyor, power and free conveyor, multi-track conveyor, and so on.

Electric control system: PLC control(for option), with or without touch screen.

3.The powder coating equipment we produced:

Electrostatic powder coating machine

Powder coating spray booth

Powder coating curing oven

Manual powder coating line

Semi-automatic powder coating line

Full automatic powder coating line

Reciprocating machine

Sieving machine

4. In order to improve the communication speed and save your time and energy and provide you the most suitable equipment, Hope you could tell us the following info:

1. The size of workpiece, especially the max size, such as length, width, height and thickness of the material/

2. The max weight of the workpiece

3. Is there any requirements about the suspension of the workpiece?

4. The material of the workpiece

5. The anticipative output for the biggest size of the workpiece(how many pcs in 8 hours)

6. The CLEAR length, width and height of the factory available for the powder coating line

7. The heating power: Liquefied Petroleum Gas, Liquefied natural gas, diesel or electric?

8. Do you need to change colors every day? How many colors do you have in total?

9. Do you need automatic painting or manual painting?

10. Do you need pre-treatment process?

If so,you like spray pre-treatment or bath pre-treatment?

11. The local electricity conditions(_V/3Phase/_Hz, -V/1phase/----Hz?)

Our standard voltage is 380V/3f/50Hz, 220V/1f/50Hz.

12. Do you have any special requirements about the package?

If not, we will pack the goods as our common package.

Production area and equipment for Electrostatic Powder Coating Plant with Heat Insulation Curing Oven

Package Show of Electrostatic Powder Coating Plant with Heat Insulation Curing Oven

Certificate of our product and company

Our Team is serving you at any time

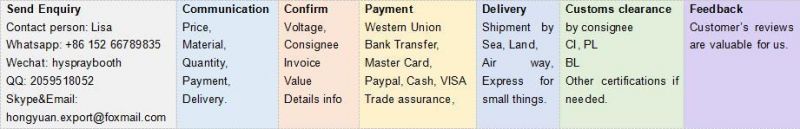

Contact person: Lisa, Mob.& : +86 152566789835

Send us inquiry for more info about Electrostatic Powder Coating Plant with Heat Insulation Curing Oven

Without communication, there is no relationship;

without respect, there is no love;

without trust, there is no reason to continue!

Happy new year to you all! Wish the best to your family!