Factory Lifetime Service! Wall Color Roof Building Tile Cold Roll Forming Machine with Mitsubishi PLC

Hangzhou Zhongyuan Machinery Factory- Type:Rolling Machine

- Forging Forming Method:Cold Roll Forming

- Power Source:Electric

- Feature:Automation

- Certification:ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:(YX25-183-1100)

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Certificate:Made-to-Order

- Certificates:ISO,CE,Soncap

- Machine Size:80000*1600*1600mm

- Machines Weight:About 8t

- Delivery Time:About 60days

- Operate Language:Engish or as Required

- Cutting:Cut to Length

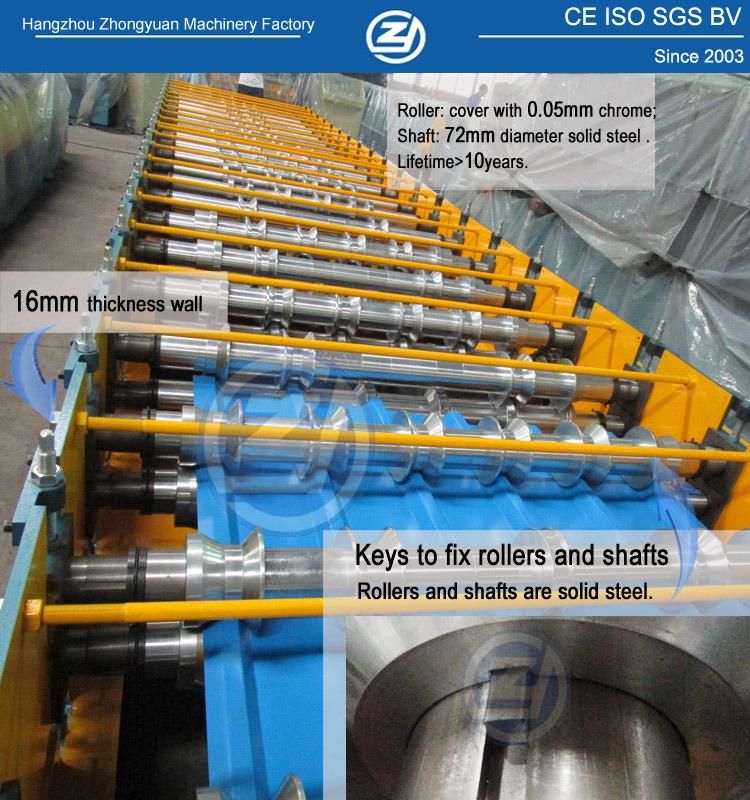

- Rollers and Shafts:Solid Steel

- Name:Tile Cold Roll Forming Machine with Mitsubishi PLC

- Transport Package:40gp+20gp Containers for One Machine

- Specification:CE SGS BV

- Trademark:Zhongyuan

- Origin:Hangzhou

- HS Code:84552210

- Production Capacity:10sets,Month

Description

Basic Info.

Model NO. (YX25-183-1100) Customized Customized Advantage Use Widely Condition New Certificate Made-to-Order Certificates ISO,CE,Soncap Machine Size 80000*1600*1600mm Machines Weight About 8t Delivery Time About 60days Operate Language Engish or as Required Cutting Cut to Length Rollers and Shafts Solid Steel Name Tile Cold Roll Forming Machine with Mitsubishi PLC Transport Package 40gp+20gp Containers for One Machine Specification CE SGS BV Trademark Zhongyuan Origin Hangzhou HS Code 84552210 Production Capacity 10sets/MonthProduct Description

Factory Lifetime Service!Wall Color Roof Building Tile Cold Roll Forming Machine with Mitsubishi PLC

Product Feature: The colored steel tiles produced by roof tile forming machine look beautiful, elegant and noble. They are widely used as the roof of garden, factory, hotel, exhibition center and villa, etc.

Machine's components: Roof tile forming machine consists of uncoiler, coil sheet guiding device, covering film device, main roll forming system, pressing device, cutting device, Hydraulic station, PLC control system and support table.

Main technical parameters:

1. Suitable material: Color steel sheet

2. Thickness of raw material: 0.5_0.6mm

3. Yield strength of material: 235Mpa

4. Working speed: About 1500-2000mm/min

5. Step distance: Adjustable according to requirement (>=250mm)

6. Power Requirement Main motor power: 5.5 Kw(Depend on final design)

Hydraulic station power: 5.5Kw(Depend on final design)

7. Uncoiler's loading capacity Max. Capacity: 5000kgs (can be increased to be 10T)

8. Controlling system: Mitsubishi PLC & converter

9. Machine's size: About 18m*1.5m*1.4m (Depend on final design)

10. Machine with CE certificate.

About us

1. Customize roll forming machines since 2003.

2. CE, ISO certificate by SGS.

3. Mitsubishi PLC controller and transducer from Japan

4.12moths warranty, lifetime technical support

5. Capacity: 12-15 sets/month

6. Delivery: In only 5-8 weeks for urgent order

7. Company occupies 6650, in which 5650 for workshops

8. Have our own tool center. 12 sets CNC machines.

9. Third party inspection: Bureau Veritas, SGS. Can provide assessment report.

10. Machine original brand: Zhongyuan

11. Set up business relationship with companies in more than 20 countries