Steel Molding Machinery/Steel Frame Machine/Stud and Truss Profile Roll Forming Machine Light Gauge Steel Framing Machine

SHANDONG TOP BUILDING MATERIALS CO., LTD.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Electric

- Feature:High Efficiency

- Certification:CCC, ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:38# 50# 75#

- Customized:Customized

- Advantage:Work Flexible

- Condition:New

- Size:50# 75# 100#

- Specification:75# 50# 100#

- Trademark:ELST

- Origin:Linyi China

- Production Capacity:1000 Set

Description

Basic Info.

Model NO. 38# 50# 75# Customized Customized Advantage Work Flexible Condition New Size 50# 75# 100# Specification 75# 50# 100# Trademark ELST Origin Linyi China Production Capacity 1000 SetProduct Description

Packaging & Delivery

| Packaging Details: | Nude packing in the container, with waterproof cloth and stow-wood. Imported computer control system is packed with waterproof cloth and card board. |

| Delivery Detail: | within 25-30 days |

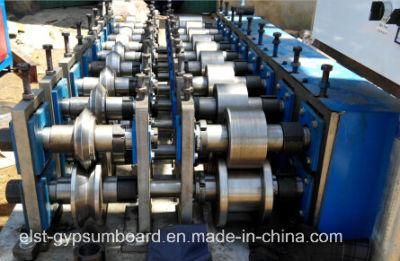

Stud and truss profile roll forming machine light gauge steel framing machine

Features of this producing line:

lower cost

high efficiency

reliable working

low energy consumption

1. Working Flow:

Decoiling--feeding---forming---cutting---finished product

2. Parts of Equipment:

Decoiler ,roll forming machine, hydraulic cutting (punching device),electric system(PLC control system),hydraulic system, stacker.

3. Techincal description:

1).Automatic inner tight decoiler

a.coil inner diameter 450mm-550mm

b. maximum width of coiling600mm

c. maximum weight of loading 2500kg

2). Main forming machine

a. number of forming steps 11rows

b. material of shaft 45# steel . Outer diameter 60mm

c.main motor power: 5.5kw

d. The speed of forming: 0-50m/min

3).Hydraulic cutter

a. material of blade:Cr12 mould steel with quenched treatment 60-62

b. cutting system :adopt advanced hydraulic drive, after forming automatic cut, no distort, no wasting , high safe factor.(tracking cutting)

4).The electrical control system

a. The Brand of display: DELTA

b.The main computer (PLC): DELTA DVP14

5).Hydraulic system

a. Adopting advanced hydraulic system of Tai Wan

b. Power:3kw

6).The equipments coating , package

a.the coating adopt international general shade-guide

b.The package :simple waterproof package.