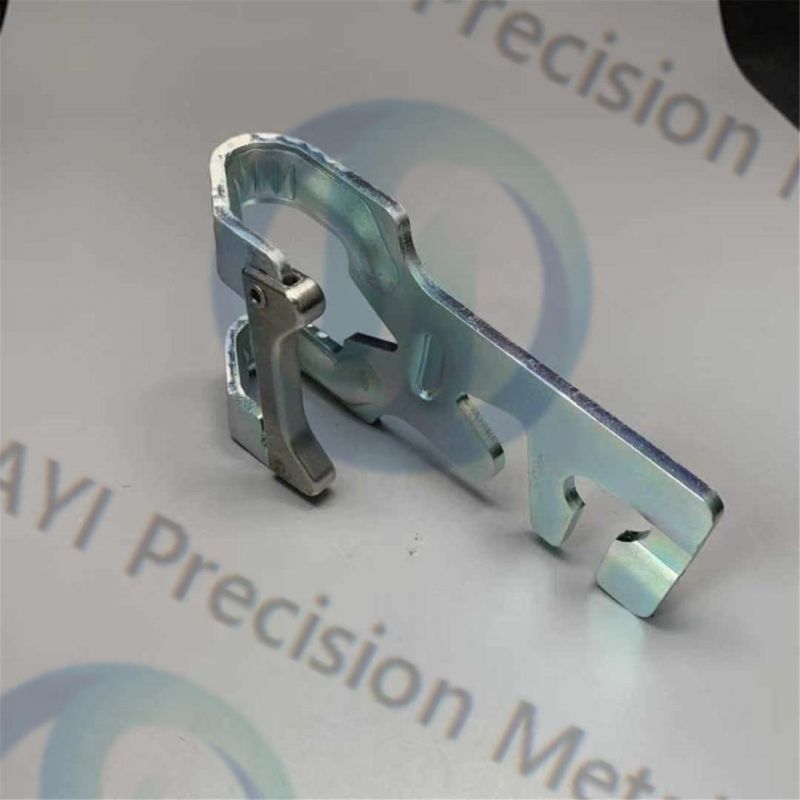

OEM High Quanlity Sheet Metal Part

HuaYi Precision Metal Co., Ltd.- Condition:New

- Certification:RoHS, GS, ISO9001

- Standard:DIN, ASTM, GB, JIS, ANSI, BS

- Customized:Customized

- Material:Stainless Steel

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Base Info

- Model NO.:HFY-129

- Purpose:Auto Parts

- Surface Treatment:Anodizing

- Machining Method:Sheet Metal

- Production Type:Mass Production

- Transport Package:Separate Packing + Wooden Cases

- Specification:Customized

- Trademark:Customized

- Origin:Customized

- Production Capacity:100000pieces,Year

Description

Basic Info.

Model NO. HFY-129 Purpose Auto Parts Surface Treatment Anodizing Machining Method Sheet Metal Production Type Mass Production Transport Package Separate Packing + Wooden Cases Specification Customized Trademark Customized Origin Customized Production Capacity 100000pieces/YearProduct Description

Description of products:

| Materials | Stainless steel |

| Min Tolerance | 0.1mm |

| MOQ | 1pcs |

| Lead Time | 5-8 days |

| QC System | 100% inspection before shipment. |

| Packagings | 1) PP bag, Standard packages, 2) Pallet or container, 3) As per customized specifications. |

| Shipment Terms | 1) 0-100kg: air freight priority, 2) >100kg: sea freight priority, 3) As per customized specifications. |

Detail Show for products

Our Company

Engineer Team

Steel Stamping fabrication, Sheet Metal Manufacturers, CNC Machining supplier in China

Steel Stamping fabrication/supplier in China

Huayi precision metals can produce moderately to highly complex parts from difficult materials with an accuracy of 0.005 mm or less. We have the most advanced machining equipment and experienced mechanics, so all orders can be completed in a very short time and on-time delivery. Huayi precision metal can provide precision milling, turning, tapping, drilling, deburring, finishing and management of external supply services.

Our workshop

How to place your order :

1. Please send us your drawings( 2D&3D) or sample.

2. Our engineering team work on them and submit a competitive quotation for you.

3. Confirm sample order and fabricate samples after you approve the quotation and submit them to you for your inspection.

4. Confirm production order after you approve samples.

5. Payment and shipping terms are negotiable.

Q&A:

Q1: How to have my components quoted?

A1: Please contact us via email and send us your drawings inclusive of 2D and 3D( STEP/X_T/PRT/ IGS/ DWG files) and detail requirements. We are pleased to sign NDA with you if you prefer. Then our engineering team will work on them and submit a competitive quotation to you ASAP.

Q2: What is the lead time for tooling and samples fabrication?

A2: The exact lead time depends on your parts specification.

The normal lead time is 12-18 days for tooling fabrication and samples.

If the tooling is not required, the lead time for samples is 10 days normally.

Q3: What's the advantage of your factory compared to other manufacturing enterprises in China?

A3: 1) Passed ISO9001-2015 certification

2) Have strong Mould and QC department

3) OEM/ODM customized services

4) Owned 4 factories

Q4: How to ship the samples and production order?

A4: We will normally ship samples via DHL, UPS or FedEx via our cooperated forwarder or freight collect. For the shipping of production order, it will be by sea or by air.

Q5: How to ensure the quality of the parts?

A5: Firstly, our team will inspect all incoming material. All parts will be 100% inspected before sending out, and then submit a Quality Inspection Report together with samples and production order.